DA200/ DA300

Bar Code Printer Service Manual

37

The printer status from

DiagTool shows “Head

Open”.

The printer carriage is open.

Please close the print carriage.

The printer status from

DiagTool shows “Out of

Paper”.

The label is installed incorrectly.

Please reinstall the label roll.

Gap/black mark sensor is not

calibrated.

Calibrate the gap/black mark sensor.

Memory full

( FLASH / DRAM )

* The space of FLASH/DRAM is full.

Delete unused files in the FLASH/DRAM.

* The connector is loose.

* Cutter jam.

* Cutter PCB is damaged.

* Plug in the connect cable correctly.

* Remove the label.

* Make sure the thickness of label is less

than 0.19 mm.

* Replace a cutter driver IC board.

Skip labels when

printing

* Label size is not specified properly.

* Sensor sensitivity is not set properly.

* The media sensor is covered with

dust.

* Check if label size is setup correctly.

* Calibrate the sensor by Auto Gap or

Manual Gap options.

* Clear the GAP/Black mark sensor by

blower.

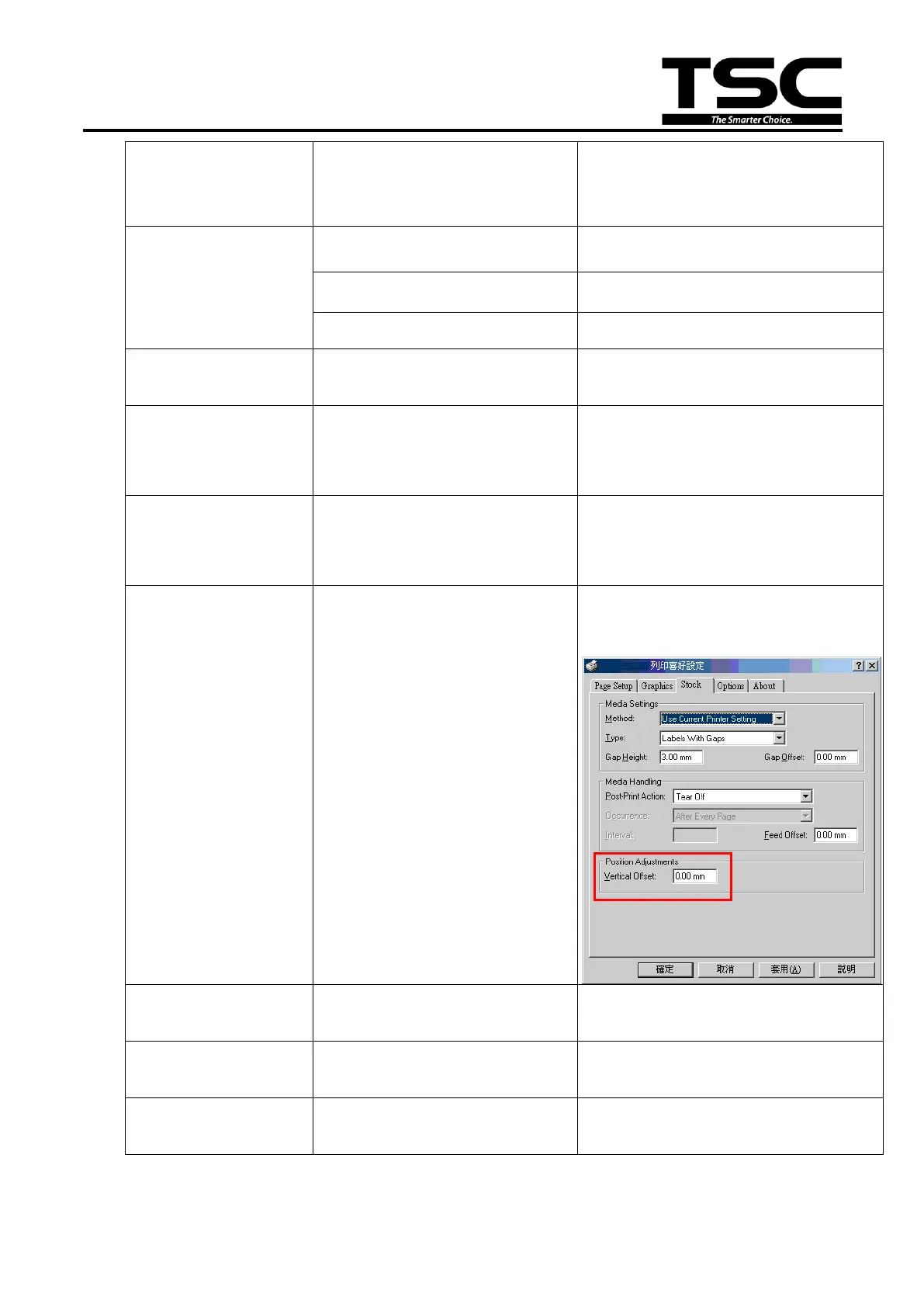

The printing position of

small label is incorrect

* Media sensor sensitivity is not set

properly.

* Label size is incorrect.

* The vertical offset setting in the

driver is incorrect.

* Calibrate the sensor sensitivity again.

* Set the correct label size and gap size.

* If using the software BarTender, please set

the vertical offset in the driver.

Missing printing on the

left or right side of label

* Wrong label size setup.

* Set the correct label size.

RTC time is incorrect

when reboot the printer

* The battery has run down.

* Check if there is a battery on the main

board.

Gray line on the blank

label

* The print head is dirty.

* The platen roller is dirty.

* Clean the print head.

* Clean the platen roller.

Loading...

Loading...