Climate Control Zoning System II installation and operation manual | Chapter 8 – Maintenance l 29

Chapter 8

Maintenance

Manual preventive maintenance

The system requires no preventive maintenance except

cleaning with a dry, soft cloth.

Warning! Do not use any detergents to clean

the Climate Control Zoning System II.

Automatic preventive maintenance

The system is equipped with an automatic exercise function

that consists of a test run designed to prevent the pump and

actuators from seizing up due to inactivity.

This exercise is run every six days ±24 hours at random.

• The pump exercise operates only if the pump has not been

activated since the last exercise. The pump is activated for

3 minutes during the exercise.

• The actuator exercise operates only if the actuators have not

been activated since the last exercise. The exercise consists

of opening and completely closing the actuators periodically.

Corrective maintenance

Fallback mode

If a thermostat is malfunctioning or not detected, the controller

executes the fallback mode to maintain the temperature in the

room until the problem is resolved.

Resetting the controller

If the controller does not work as expected, for example

due to a hang-up, it can be reset to solve the problem.

1. Disconnect and reconnect the controller to AC power.

Controller LEDs

Uponor recommends occasionally checking the power

LED on the controller for alarms. The power LED ashes

continuously for general alarms. Determine which thermostats

are issuing alarms by removing the cover. If a channel

LED is indicating an error, check the function and batteries

of the registered thermostat.

The controller power LED is on during normal operation.

All the channel LEDs are off when there is no current or

waiting actuator activity. The LEDs turn on when the

corresponding actuators are activated or start ashing

when they are awaiting activation.

Up to eight actuators in six rooms can be in the opening process

at the same time. If a slave module is installed, the LEDs of the

seventh and subsequent actuators ash while they are waiting

for the previous actuators to be fully open.

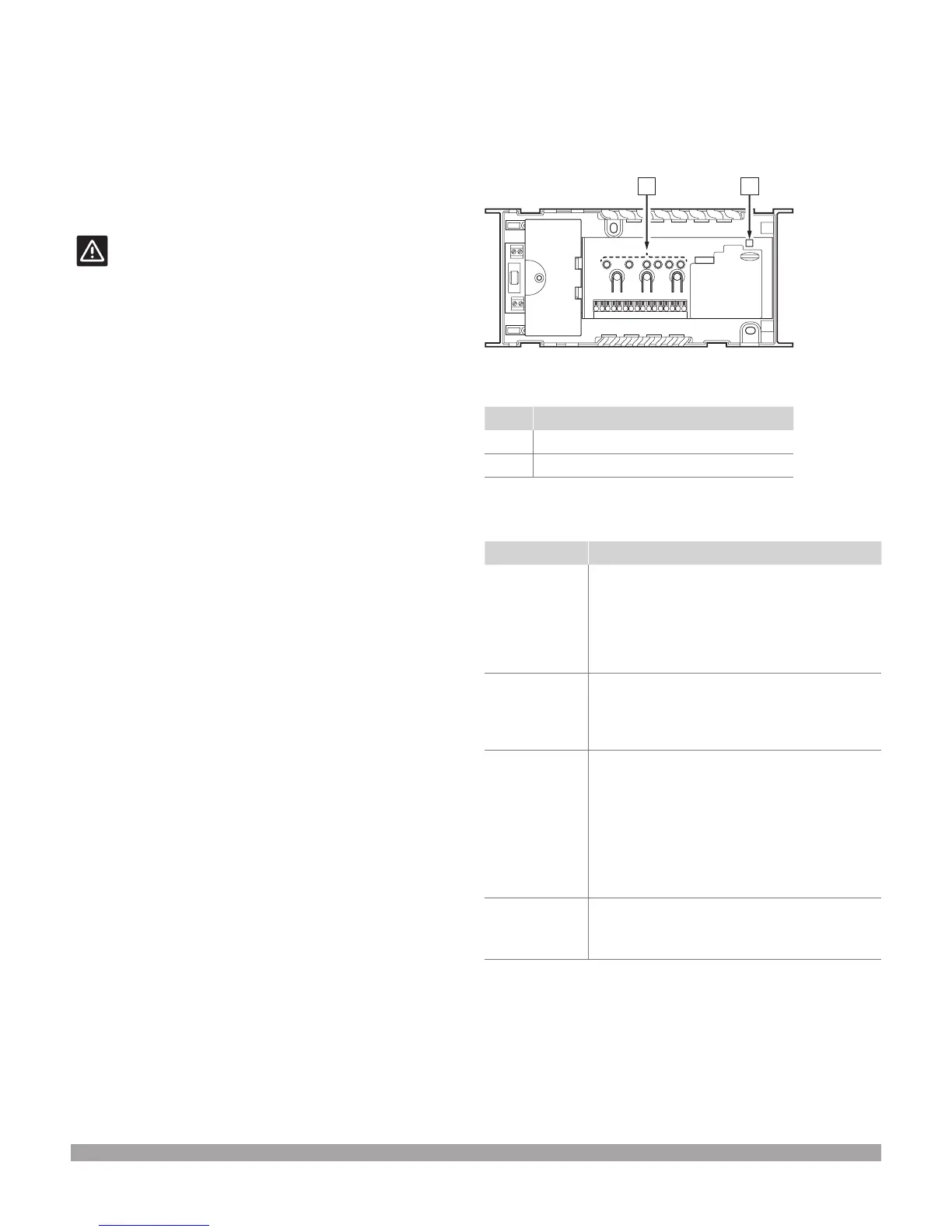

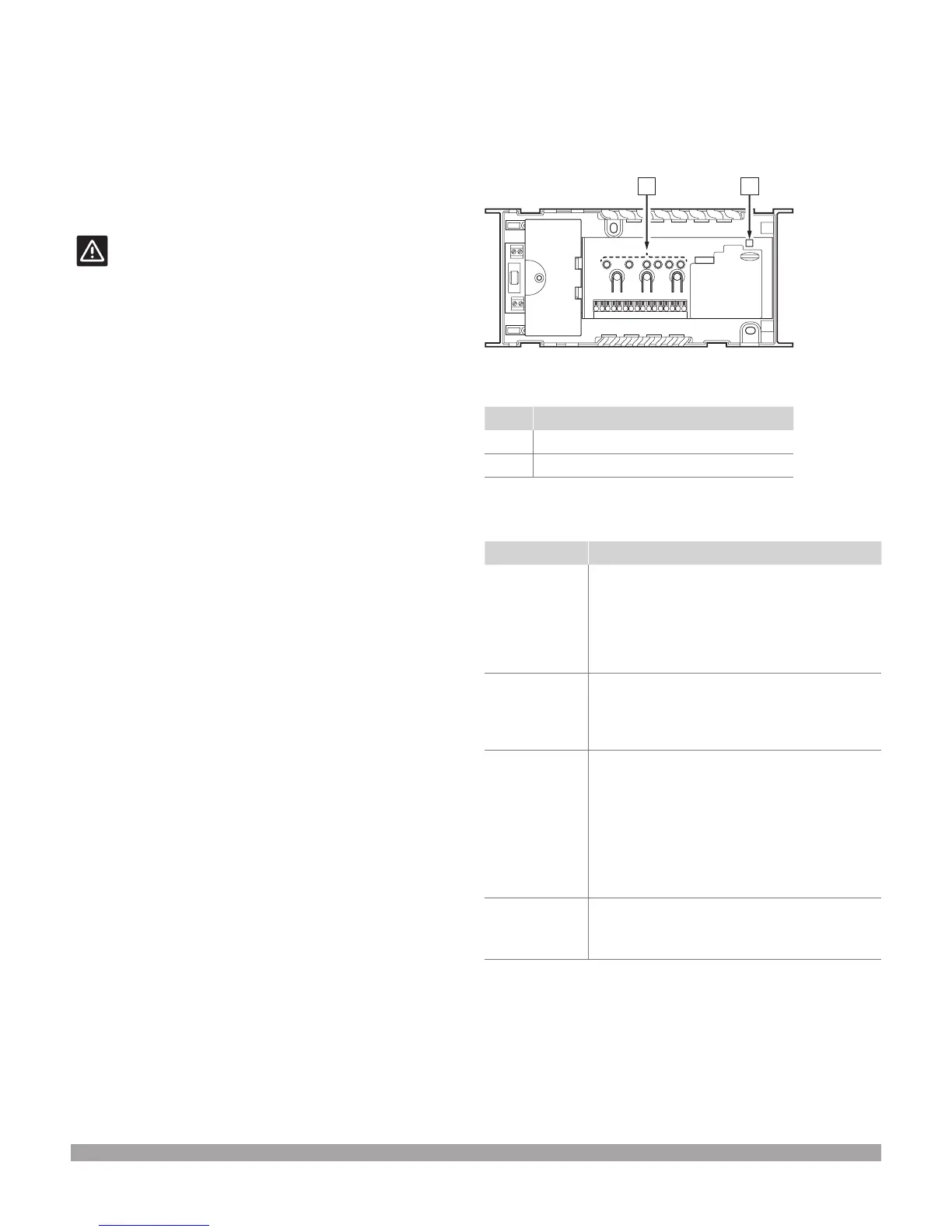

The illustration below shows the position of the controller LEDs.

Item Description

A Power LED

B Channel LEDs

The table below describes the status of the base unit LEDs.

LED Status

Power The base unit power LED is always on and ashes

when a problem occurs, such as:

• Loss of radio transmission from a thermostat

for more than 1 hour

• Loss of radio transmission from a timer or an

interface for more than 15 minutes

Channel during

run mode

• Red, on – actuators activated

• Red, ashing – thermostat communication

error or low battery indication

• Off – no demand for heating or cooling

Channel during

registering

mode

• Red, on – thermostat registered but with

communication errors

• Green, on – thermostat registered and

communication is OK

• Red, ashing – selector pointing at channel

• Green, ashing – channel selected to

be registered

• Off – channel not pointed, nor registered

Channel during

forced mode

• Red, on – actuators activated

• Red, ashing – selector pointing at channel

• Off – channel not pointed, nor activated

Figure 8-1: Controller LEDs

Loading...

Loading...