Series 613 OPERATION

984360EC Edition 12.08.2022 109/

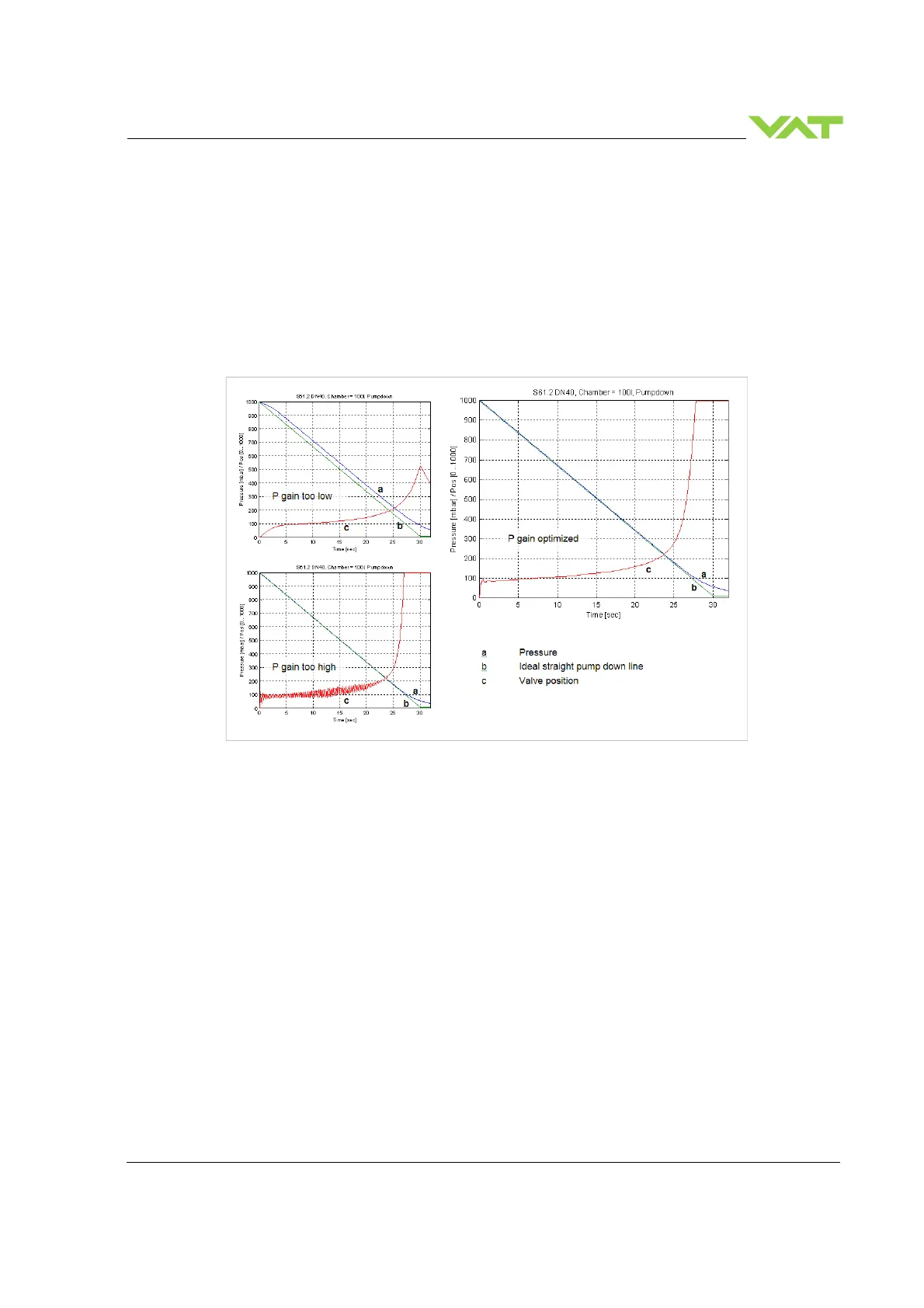

Optimizing I-Gain

Start with P-Gain set to half of the value found when optimizing P-Gain and set I-Gain to 1.0.

Keep the P-Gain constant.

If the pressure follows the ideal pump/venting line with significant delay, the I-Gain is too low.

If the pressure oscillates around the ideal pump/venting line or if the valve position oscillates, I-Gain is

too high.

I-Gain is optimized if the pressure follows the ideal pump down line closely and the valve position is

not oscillating at all.

Example:

Optimizing I-Gain

I-Gain is responsible to reach the setpoint. If reaching setpoint is not important (e.g. setpoint is 0)

leave the I-Gain at 0. Otherwise start with P-Gain set to half of the value found when optimizing P-

Gain and set I-Gain to 0.1. Keep the P-Gain constant. Start again the pump down. Check how the

pressure reaches the setpoint:

If the setpoint is reached too slowly increase I-Gain

If there is an undershoot increase I-Gain

Required information for support:

• Go to ‘Tools / Create Diagnostic File’ in ‘Control Performance Analyzer’ and save file

• Pressure / flow / gas conditions to be controlled

• Chamber volume

• Pumping speed (l/s) and pump type (e.g. turbo pump)

• System description

• Problem description

Send diagnostic file with and all required information to tuning-support@vat.ch

Loading...

Loading...