VESDA

®

LaserPLUS Product Guide

27

1.11 Preliminary Systems Check

A preliminary systems check is required after installing the LaserPLUS detector, before it is

commissioned for use. The check can be conducted by connecting the detector to a LCD

Programmer or using VConfig PRO, or VSM3 PC based software. The preliminary systems

check includes:

• Conducting a VESDAnet communications check

• Selecting pipes in use

• Accepting factory default configurations, or changing to site requirements

• Normalizing the air flow

• Conducting a basic pass/fail smoke test

• For details on preliminary systems check refer to the LCD Programmer or the relevant

software manuals

Refer to the VESDA LCD Programmer and Commissioning Guides for further details.

1.12 Maintaining the LaserPLUS detector

To maintain the VESDA LaserPLUS at its peak performance the maintenance schedule given

below should be followed. Maintenance can be conducted by the original installer, a VESDA

distributor, or a service contractor. To work effectively the LaserPLUS detector needs to be

supported by a well designed pipe network. The VESDA Maintenance Manual contains a

schedule for pipe network maintenance.

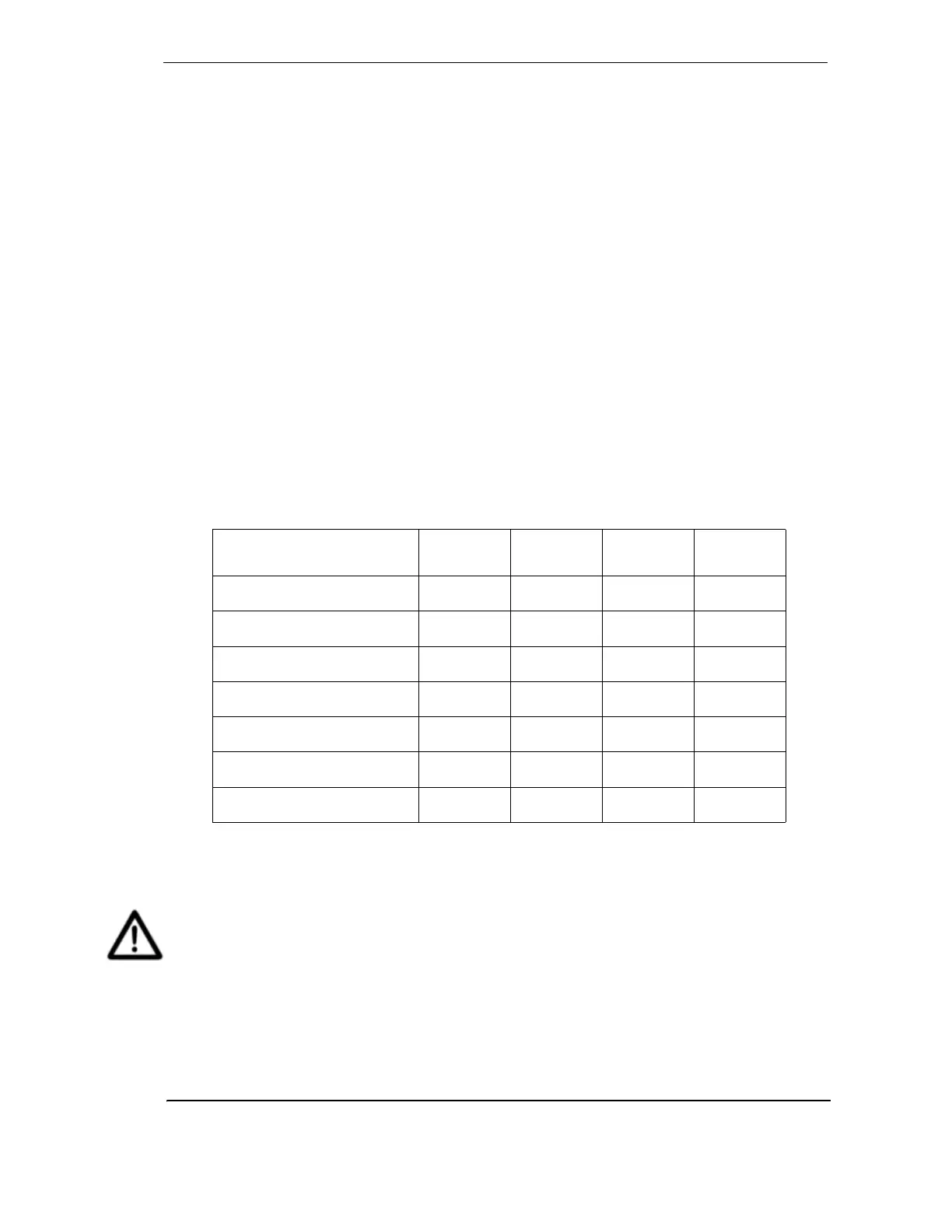

Table 9 - Maintenance schedule for LaserPLUS detector

Note: The frequency of maintenance checks could vary depending upon local codes and

standards and the environment of the installation.

Caution: While a VESDA Zone is isolated, no fire warnings will be issued by the LaserPLUS

detector and any fire will go undetected. Prior to any maintenance or testing:

- Inform appropriate supervising authority about the risk associated with isolating a

VESDA Zone.

- Check to see if the LaserPLUS detector is also being used by third party

- Ensure that any ancillary devices dependent on the LaserPLUS detector are enabled

by the isolation before work is begun.

Maintenance Check Quarterly

Six

Monthly

Annual

Every Two

Years

Power Supply

Check Pipe Network

Filter Inspection

Pipe Integrity Smoke Test

Check Pipe Flow

Clean Sampling Point.

Flush Pipe Network

Loading...

Loading...