- Check the guide shoes for the variator back-plate

are not worn.

- Check there is no wear in the roller housing, and

the surfaces in contact with the belt on either of the

pulley halves.

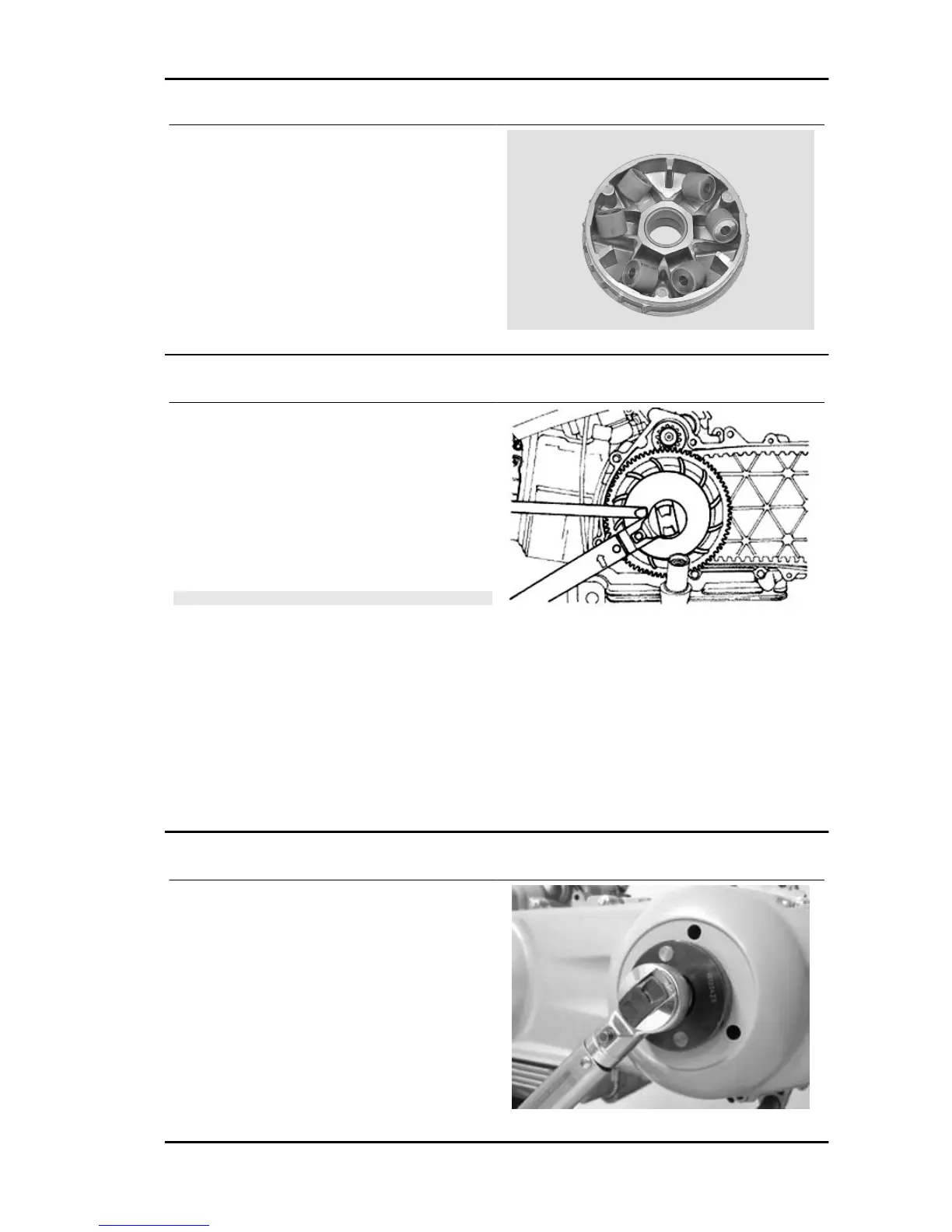

Refitting the driving pulley

- Reassemble the parts of the unit (internal lining,

fixed half-pulley, external lining, drive, belleville

washer and nut), spread recommended product

on the thread and tighten the nut to the prescribed

torque.

- Avoid half-pulley rotation using a calliper span-

ner.

N.B.

REPLACE THE NUT WITH A NEW ONE AT EVERY REFIT

Specific tooling

020368Y driving pulley lock wrench

Recommended products

Loctite 243 Medium strength threadlock

Medium Loctite 243 threadlock

Locking torques (N*m)

Locking torque 75 to 83

Refitting the transmission cover

- Check that there are 2 centring dowels and that

the sealing gasket for the oil sump on the trans-

mission cover is adequately fitted.

- Replace the cover and tighten the 10 screws to

the specified torque.

- Refit the oil loading cap/bar.

- Refit the steel washer and the driven pulley nut.

- Tighten the nut to the prescribed torque using the

lock wrench and the torque wrench tools.

Vespa LX 125 - 150 i.e. Engine

ENG - 103

Loading...

Loading...