95

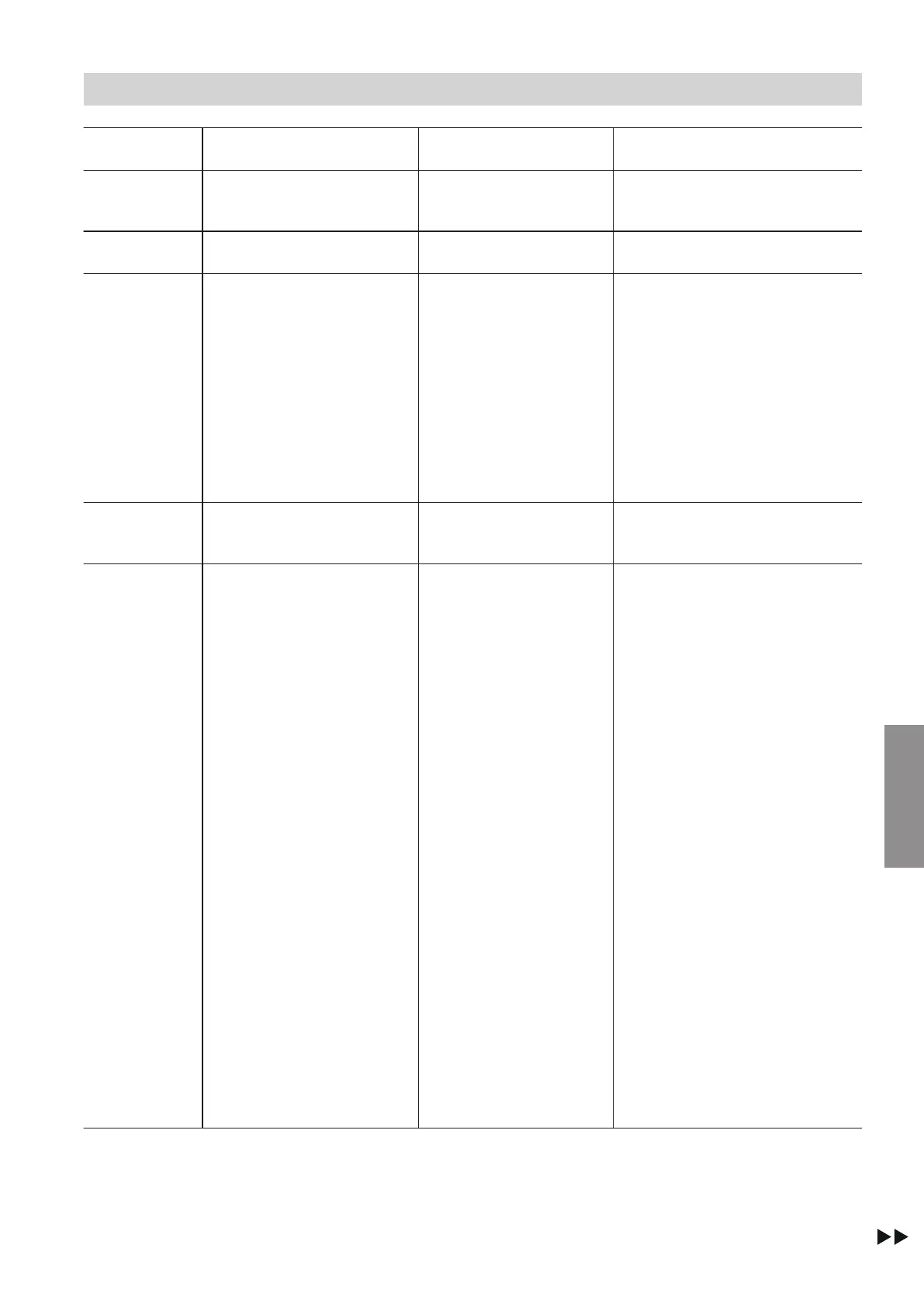

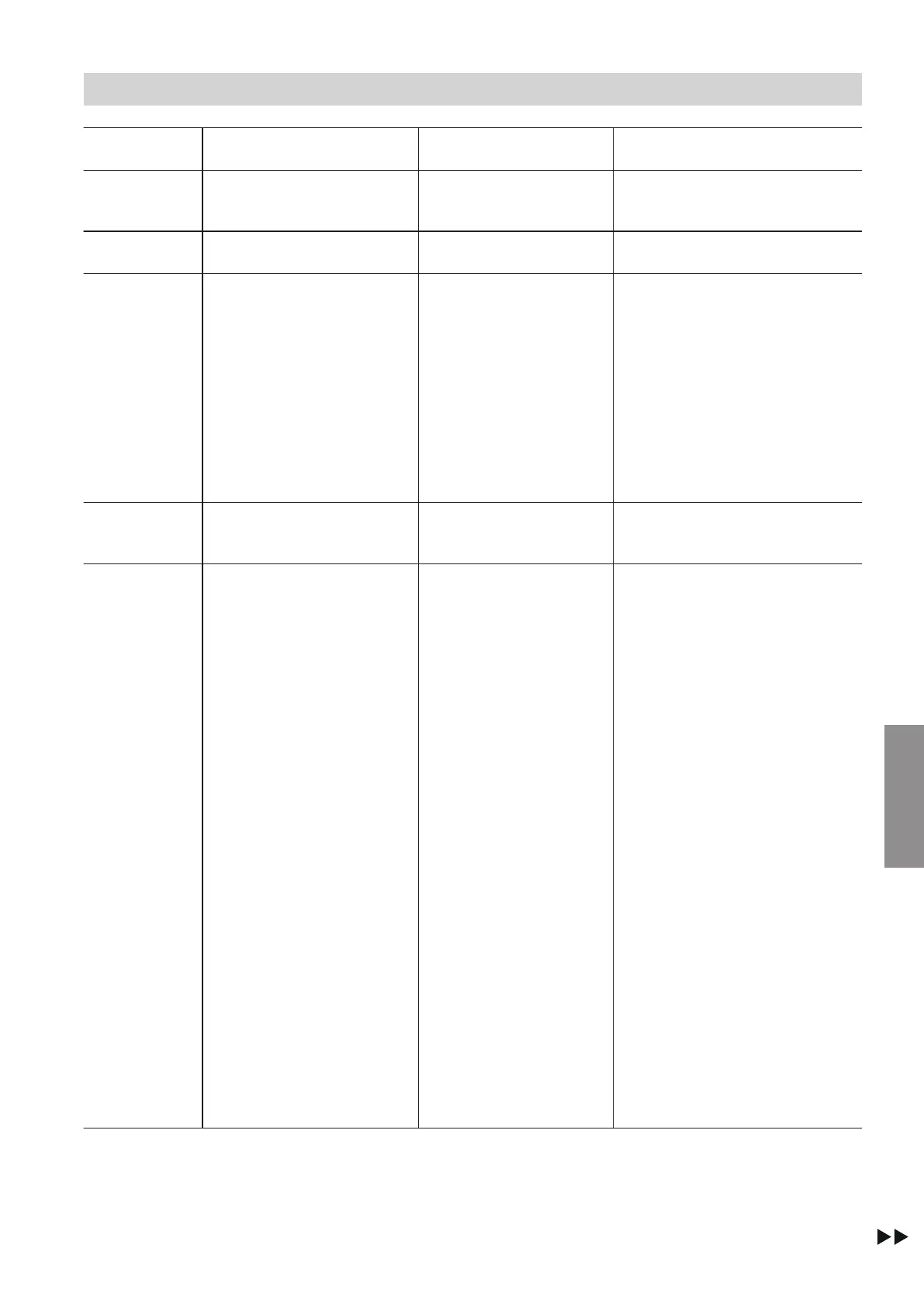

Displayed fault

code

System characteristics Cause Measures

F.365 Burner in a fault state Relay contact gas valve

feedback implausible. Re-

lay contact is sticking.

Replace BCU burner control unit

(see page 109).

F.366, F.367 Burner in a fault state Gas valve electricity sup-

ply does not turn off.

Replace BCU burner control unit

(see page 109).

F.369 Burner in a fault state Flame is lost immediately

after flame formation (dur-

ing safety time)

Check gas supply (gas pressure

and gas flow switch).

Check balanced flue system for

flue gas recirculation.

Check ionisation electrode for the

following:

■

Clearance to burner gauze as-

sembly.

■

Contamination on electrode.

Reset the appliance.

F.370 Burner in a fault state Fuel valve or modulation

valve will not close.

Reset the appliance.

If fault occurs repeatedly, replace

fan unit.

F.372 Burner in a fault state Repeated flame loss dur-

ing calibration

■

Check ionisation electrode and

connecting cable.

■

Check plug-in connections for

loose contacts.

■

Check flue system. Remove flue

gas recirculation if required.

■

Check system for condensate

backup.

■

Visually inspect gas solenoid

valve inlet and strainer on the in-

let side for contamination.

Note

To prevent water damage, detach

fan unit before removing the burn-

er. Deposits on the electrodes indi-

cate foreign bodies in the combus-

tion air.

Check the installation room and

flue system for causes of the de-

posits. For example: Laundry de-

tergents, cleaning agents, toilet-

ries, deposits in the ventilation air

supply (chimney). If burner gauze

assembly and ionisation electrode

have been replaced, also clean fan

unit, gas/air channel and Venturi

extension.

Reset the appliance.

Troubleshooting

Fault messages (cont.)

5593201

Diagnosis

Loading...

Loading...