11. Testing the automatic gate system.

It is necessary to test all the accessories connected to the control unit, especially the safety devices such as the sensitive edges and photocells.

Remember that the photocells reverse the movement of the gate only during closing and the sensitive edges and/or internal photocells, if engaged

during opening, reverse the movement of the gate for 1.5 seconds, while if engaged when closing they fully re-open the gate.

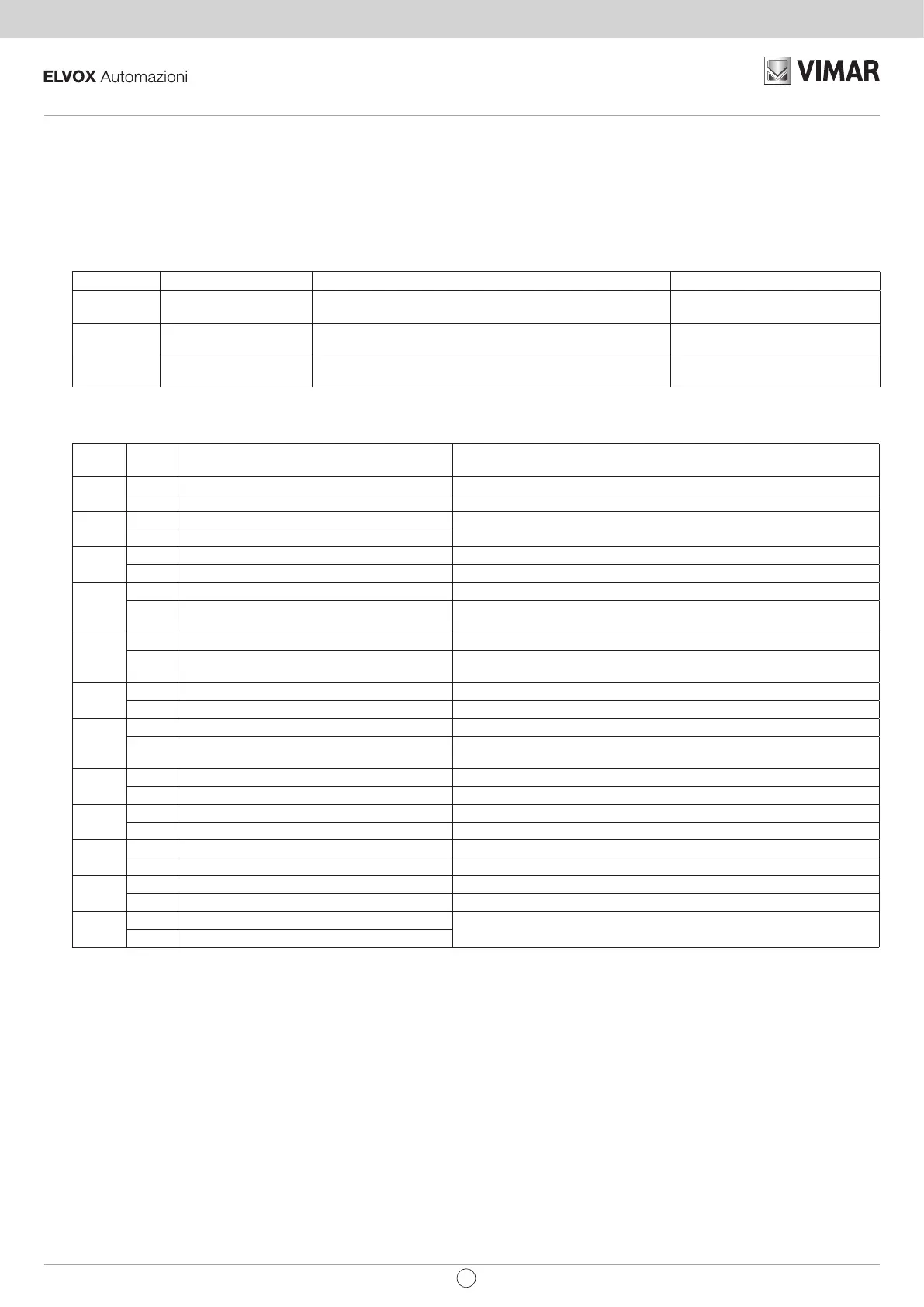

12. Trimmer for adjustments.

Trimmer Function Description Range

TR1 - DELAY Pause time

With Dip switch 1 ON, it adjusts the amount of time during

which the gate remains stationary before automatic closing.

From 1 to 130 seconds, maximum,

clockwise

TR2 - TORQ Motor torque With Dip switch 8 OFF, it adjusts the motor torque.

From 20 to 100%, maximum,

clockwise

TR3 - SL Deceleration speed

It adjusts the deceleration speed.

If turned completely clockwise, deceleration is excluded

From 0 to 100%, maximum, clock-

wise

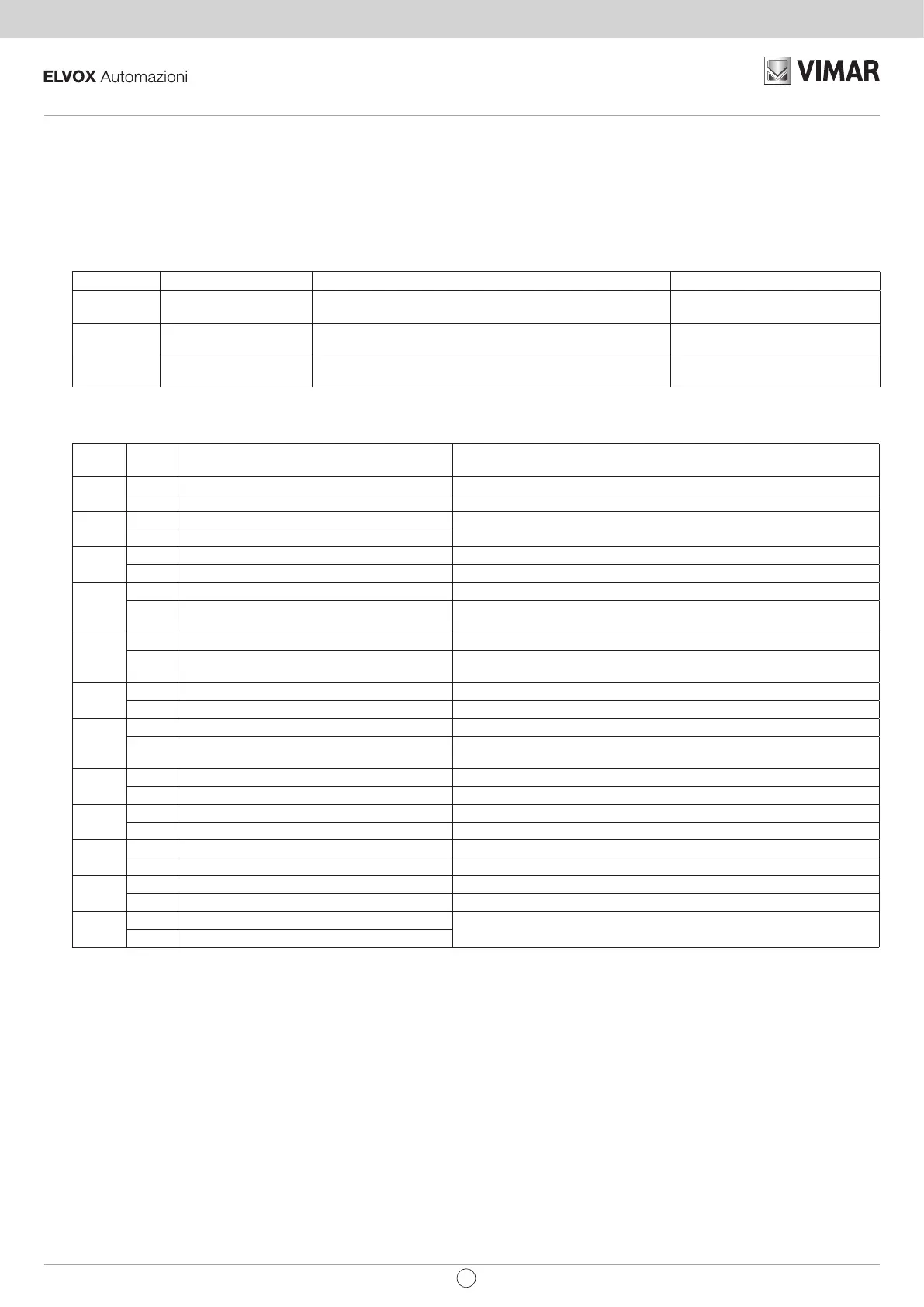

13. Dip switch functions.

Num-

ber

Sta-

tus

Function Description

DIP 1

OFF Automatic closing disabled -

ON Automatic closing enabled The open gate is closed automatically after the pause time.

DIP 2

OFF Operating logic: Opens-Stops-Closes-Stops

It modies the operating sequence of inputs SEQ (sequential) and PED

(pedestrian) also via remote control.

ON Operating logic: Opens-Closes

DIP 3

OFF Courtesy function on photocell disabled -

ON Courtesy function on photocell enabled Reduction to 5sec of the residual pause time after passing over photocells.

DIP 4

OFF Collective operating logic disabled -

ON Collective operating logic enabled

When opening the gate ignores any controls and reloads the pause time

when on pause.

DIP 5

OFF Pre-ashing disabled -

ON Pre-ashing enabled

3 seconds before the start of each movement, the ashing lamp begins to

ash.

DIP 6

OFF Flashing controlled by the control unit. It congures the output for ashing lamps without independent ashing.

ON Flashing built into the ashing lamp. It congures the output for ashing lamps with independent ashing.

DIP 7

OFF Hammering disabled -

ON Hammering enabled

It generates instant hammering to hook (at the end of closing) or release

(at the beginning of opening) the electrical lock.

DIP 8

OFF Force adjustment enabled. Possibility of adjusting the force of the motors using trimmer TR2 TORQ.

ON Force adjustment disabled. Motor force at maximum. Trimmer TR2 TORQ disabled.

DIP 9

OFF “Soft” start disabled -

ON “Soft” start enabled It slows down the start of each movement.

DIP 10

OFF

Output +P.OUT for 2

nd

radio channel. It enables use of the 2

nd

remote control channel.

ON Output +P.OUT for safety device test. It checks the operation of the safety devices if connected to +P.OUT.

DIP 11

OFF Input P.IN normally open For use on a possible open-only push button

ON Input P.IN normally closed For use on a possible sensitive edge

DIP 12

OFF Sensitive edge with electro-mechanical switch

It congures the type of sensitive edge. In only operates with DIP 11 ON

ON Sensitive edge with resistive load 8.2 Kohm

35

SW230.T / SW230.T.120

EN

Loading...

Loading...