Page 26 Vision Microsystems Incorporated

The most common installation problems are related to poor quality

terminations.

Wiring Markings

The VM1000C is supplied with special Teflon insulated Chromel- Alumel

factory assembled wiring harness configured for the correct number of

cylinders. The wire harness is marked E1= EGT-1, C1= CHT-1, etc.

NOTE: Unlike most other EGT & CHT installations the probe wire

length is not critical and should be trimmed to any length as required

for a clean installation. Do not extend the thermocouple wire with

copper wire.

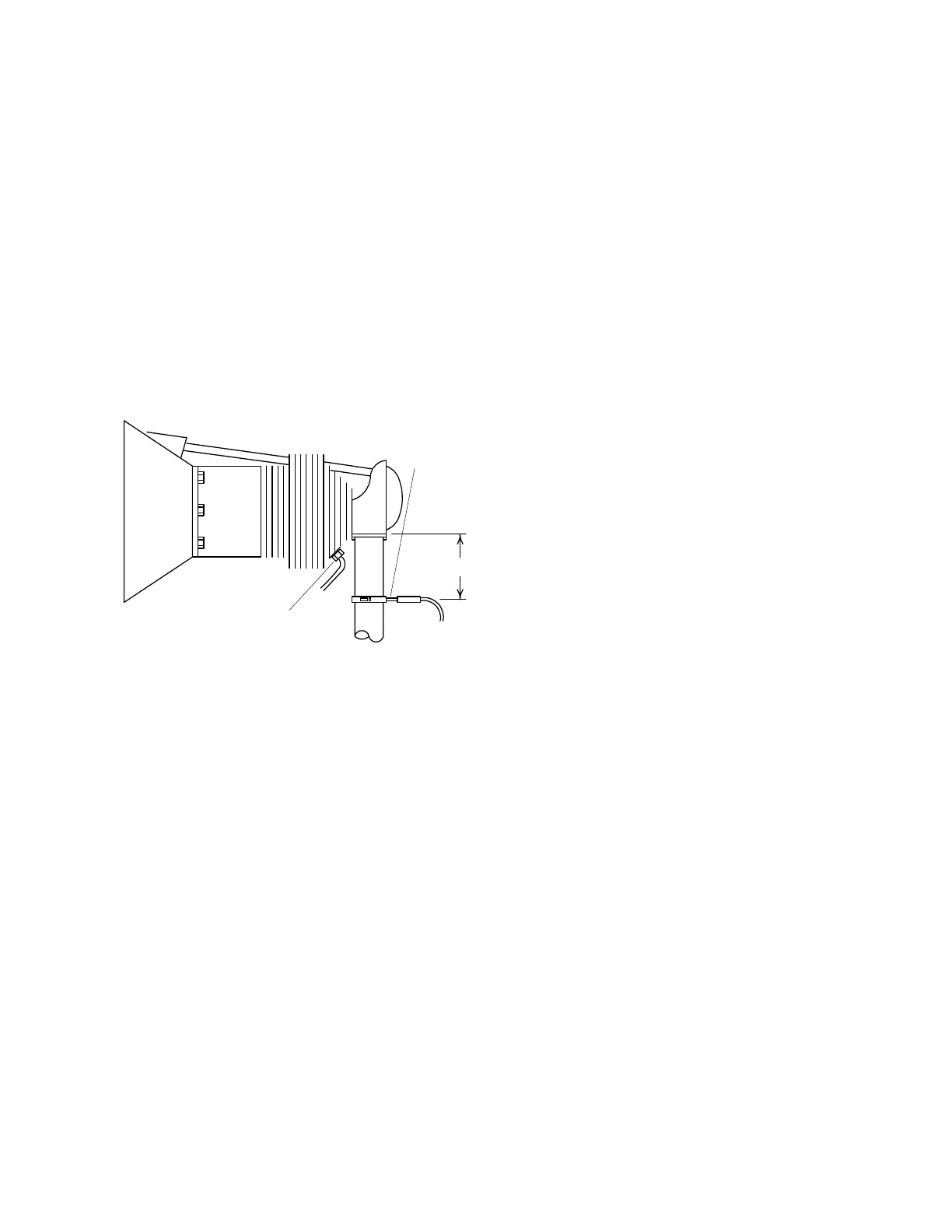

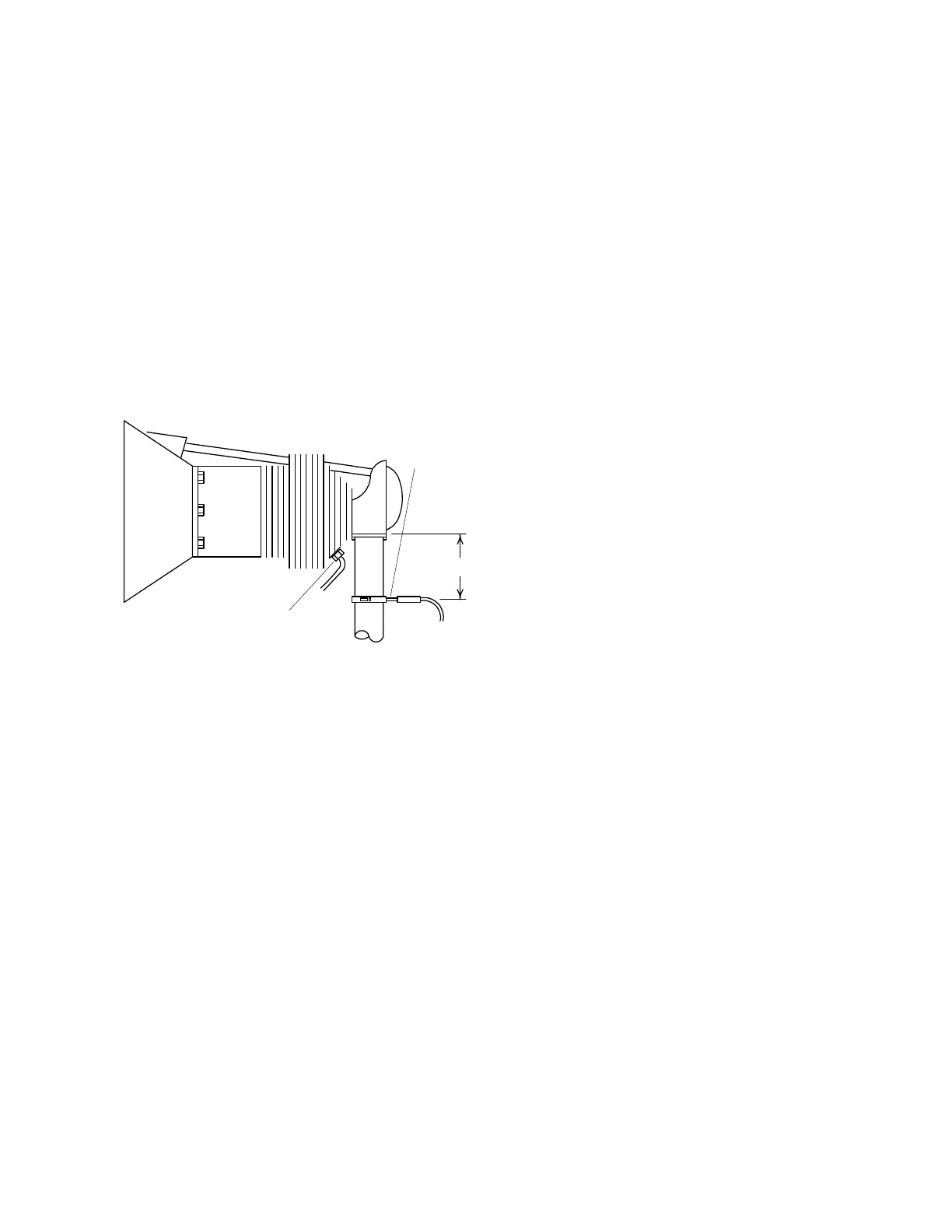

Exhaust Gas Temperature Probe (EGT) Installation

Use the J2 connector harness 700700 or 700702 labeled E1 through E4

or E6. Remove the existing EGT gage and Probe. Replace with VISION

MICROSYSTEMS probe M-111 in all exhaust stacks.

2" to 4"

EGT probe

Drill no. 40

pilot hole,

then no. 30

hole.

CHT probe

exhaust stack

The Model M-111 Probe will fit any engines where the existing holes in

the exhaust stack are 1/8" to 1/4" in diameter. If no hole exists, it will

require the drilling of a 1/8" diameter hole and ream to fit. It is important

that each probe be mounted the same distance from its exhaust stack

flange. A nominal distance of 2 to 4 inches from the exhaust flange is

recommended. If the recommended distance is impractical because

of obstructions, slip joints or bends in the exhaust system then position

the probes a uniform distance from the flange as space permits. Do not

mount probes in slip joints. Be certain to locate all holes BEFORE

Loading...

Loading...