VM1000C Pilot’s Guide Page

27

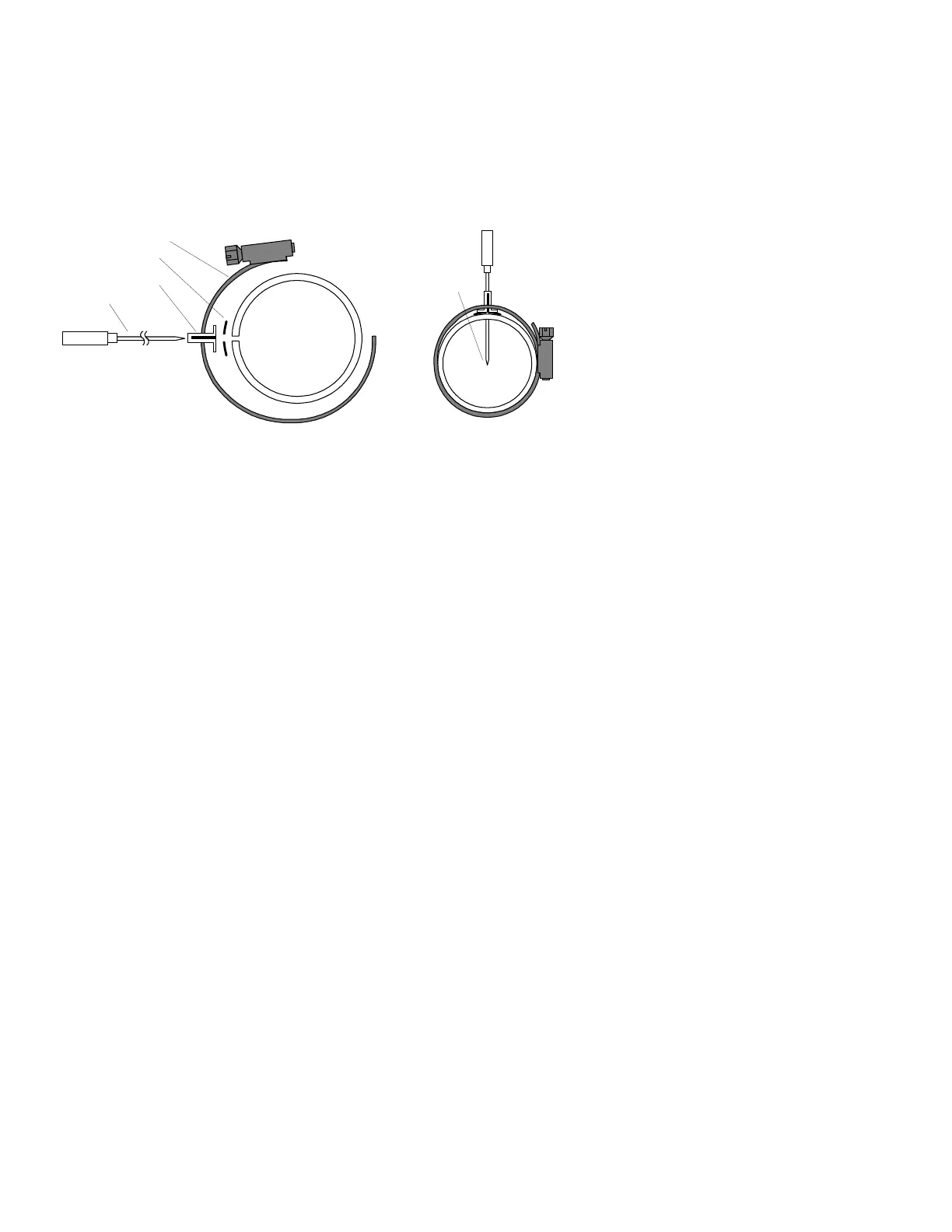

drilling to ensure that nothing interferes with the probe, clamp, screw or

wire. Careful matching of probe position will provide best temperature

measurements.

Insert the probe in the exhaust or previously drilled hole so that the tip of

the probe is in the center of the exhaust stream. Tighten the stainless

steel clamp to a torque of 45 in/Lbs. Cut off the excess strap close to the

screw.

Position probe

in approximate

center of

exhaust

Probe

Clamp

Thimble

note orientation of

slot

Seal Washer

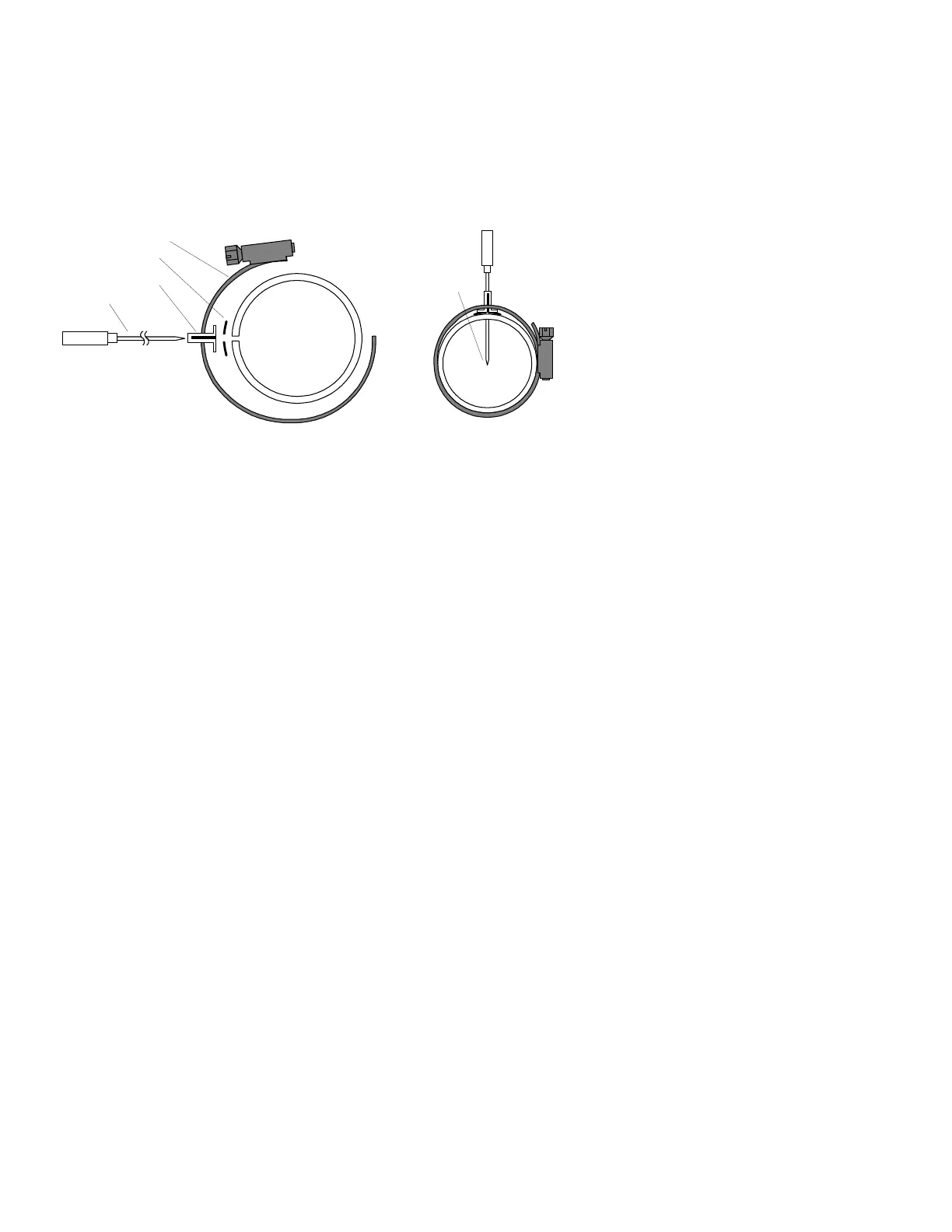

Turbine Inlet Temperature (TIT) Probe Installation (Optional)

Use the J1 connector harness 700200 and insert the yellow wire into the

connector pin 16 and the red wire into pin 17. The standard TIT probe PN

M111-T with a #48 clamp is placed in the exhaust stack accumulator to a

maximum depth of 1/2 inch and approximately 4 inches from the turbine

inlet if possible, on the waste-gate side of the turbine.

TIT for second Turbine Inlet Temperature

Use the J1 connector harness 700200 and insert the yellow wire into the

connector pin 18 and the red wire into pin 17The standard VISION

MICROSYSTEMS TIT probe P/N M-111-T with a special clamp is placed

in the exhaust stack accumulator to a maximum depth of 1/2 inch and

approximately four inches from the Turbine inlet if possible, on the waste

gate side of the turbine.

Cylinder Head Temperature (CHT) Probe Installation

Use the J2 connector harness 700700 or 700702 labeled C1 through C4

or C6. The VISION MICROSYSTEMS probe is a bayonet probe P/N

5050-T that has a captive 3/8-24 boss that is screwed into the head of

each cylinder.

Loading...

Loading...