86

EPG-SPRINT / EPG-SPRINT X

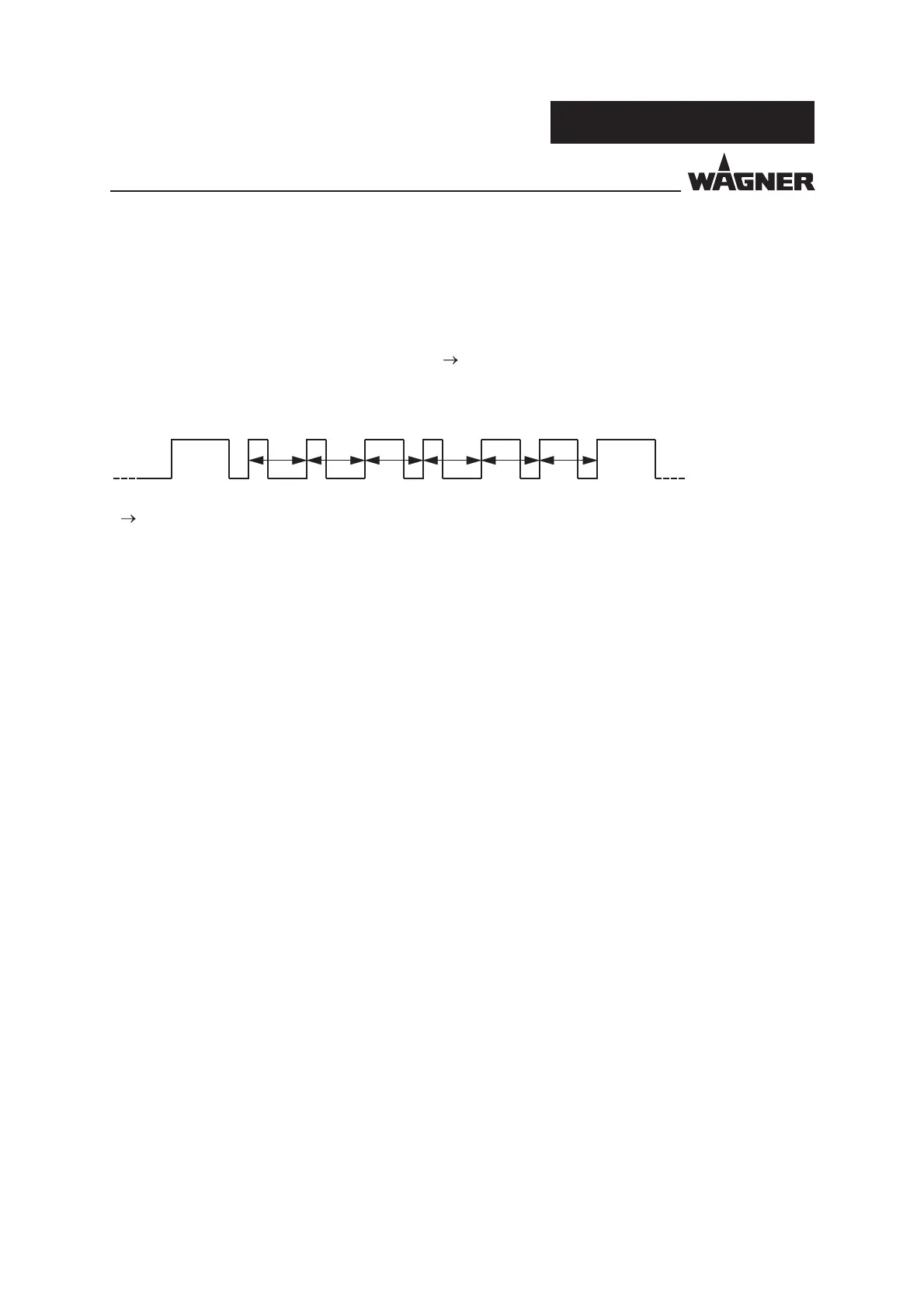

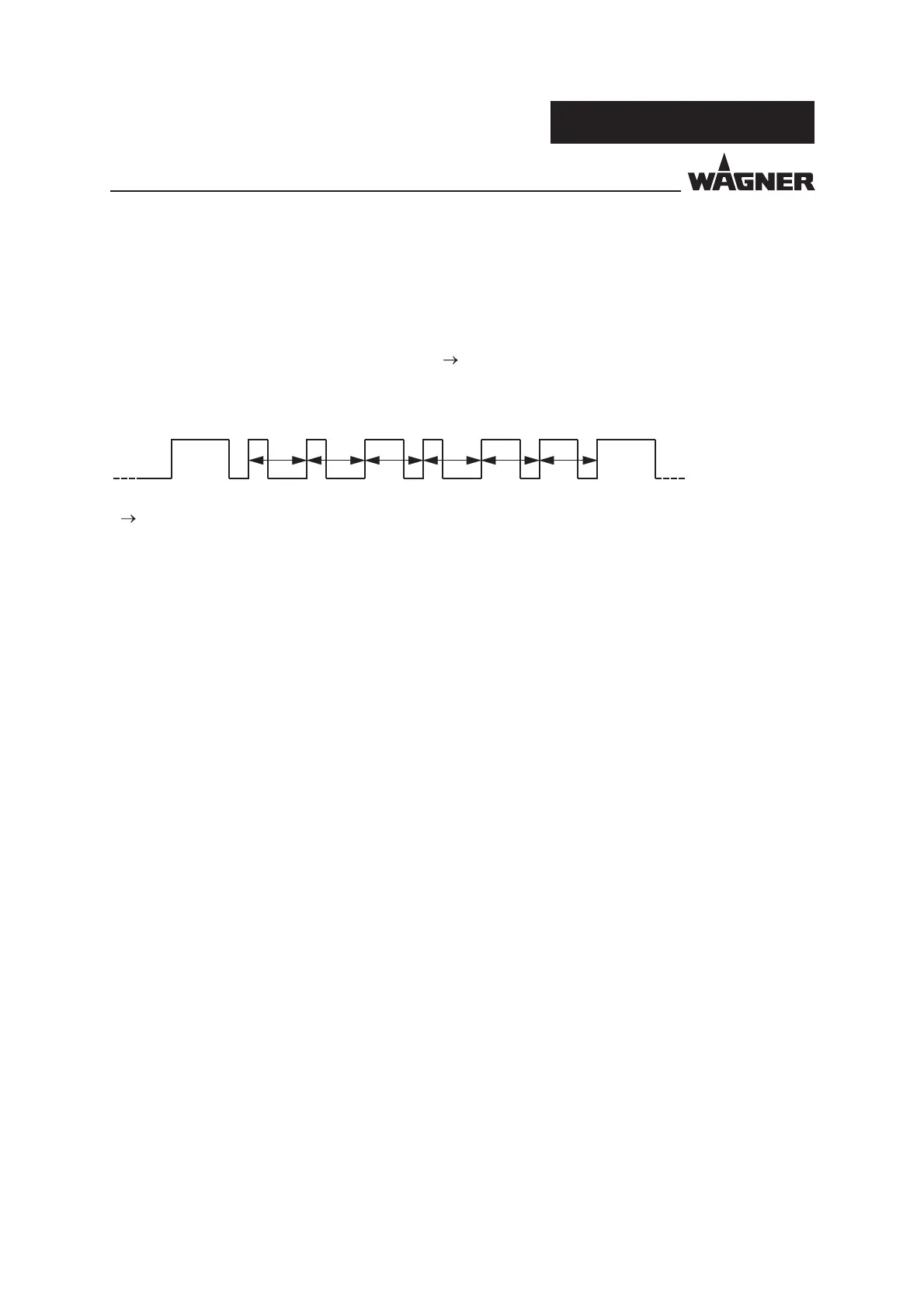

60ms

60ms 60ms 60ms 60ms

60ms

60ms

20ms 20ms 20ms

20ms 20ms 20ms

20ms

60ms

60ms

„0“ „0“ „1“ „0“ „1“

„1“

P_01285

SERVICE MANUAL

VERSION 09/2017 ORDER NUMBER DOC2309350

Example for accessing recipe 11

If recipe 11 is to be selected by way of example, the 0 0 1 0 1 1 data bit combination must be transferred.

The complete transfer frame is shown below:

Example: accessing recipe 11 binary 001011

decimal 11

Start sequence Stop sequence

1

Recipe 60+60+20+6*60+60 = 560

Conditions:

Recipe: 1 … 50 [range of values]

The control unit must be in coating mode (not standby, not ush, not con guration menu, not when starting the

unit, etc.).

The C16 setting parameter must be set to "on" in the "Service" con guration menu.

The maximum/minimum times of the transfer protocol must be observed.

Flush function (via the same protocol):

Flush can be activated/deactivated via the serial transfer protocol.

There are two di erent ush modes:

– Continuous ushing Transfer "Recipe Number" 60 to start

– Pulse ushing Transfer "Recipe number" 62 to start

Flushing can only be activated if the control unit is in coating mode (not standby, not ush, not con guration

menu, etc.). The coating must be OFF, .e.g., "Prima Input EPG ON" to LOW.

The C16 setting parameter must be set to "on" in the "Service" con guration menu.

The maximum/minimum times of the transfer protocol must be observed.

– Command for activating continuous ush function: Transfer "Recipe number" 60

– Command for activating pulse ush function: Transfer "Recipe number" 62

– Command for deactivating continuous ush function: Transfer "Recipe number" 61 or 0

The same protocol can be used to correct the powder quantity (for description, see page 87).

Loading...

Loading...