Installation manual

33

487 14 59 11 - TD30 TD50 TD75 US

Evacuation system

Exhaust duct

• The exhaust duct must be smooth on the inside (low air

resistance).

• The exhaust duct must lead to the outdoors.

• The exhaust duct must lead clear of the building as

condensation may cause frost damage to the building.

• The exhaust duct must be protected against rain and foreign

objects.

• The exhaust duct must have gentle bends (fig. 1).

• The exhaust duct must not be a shared duct between dryers

and appliances using gas or other fuels as their energy

source.

When several dryers share an exhaust duct:

• The exhaust duct diameter must increase after each dryer

(fig. 2).

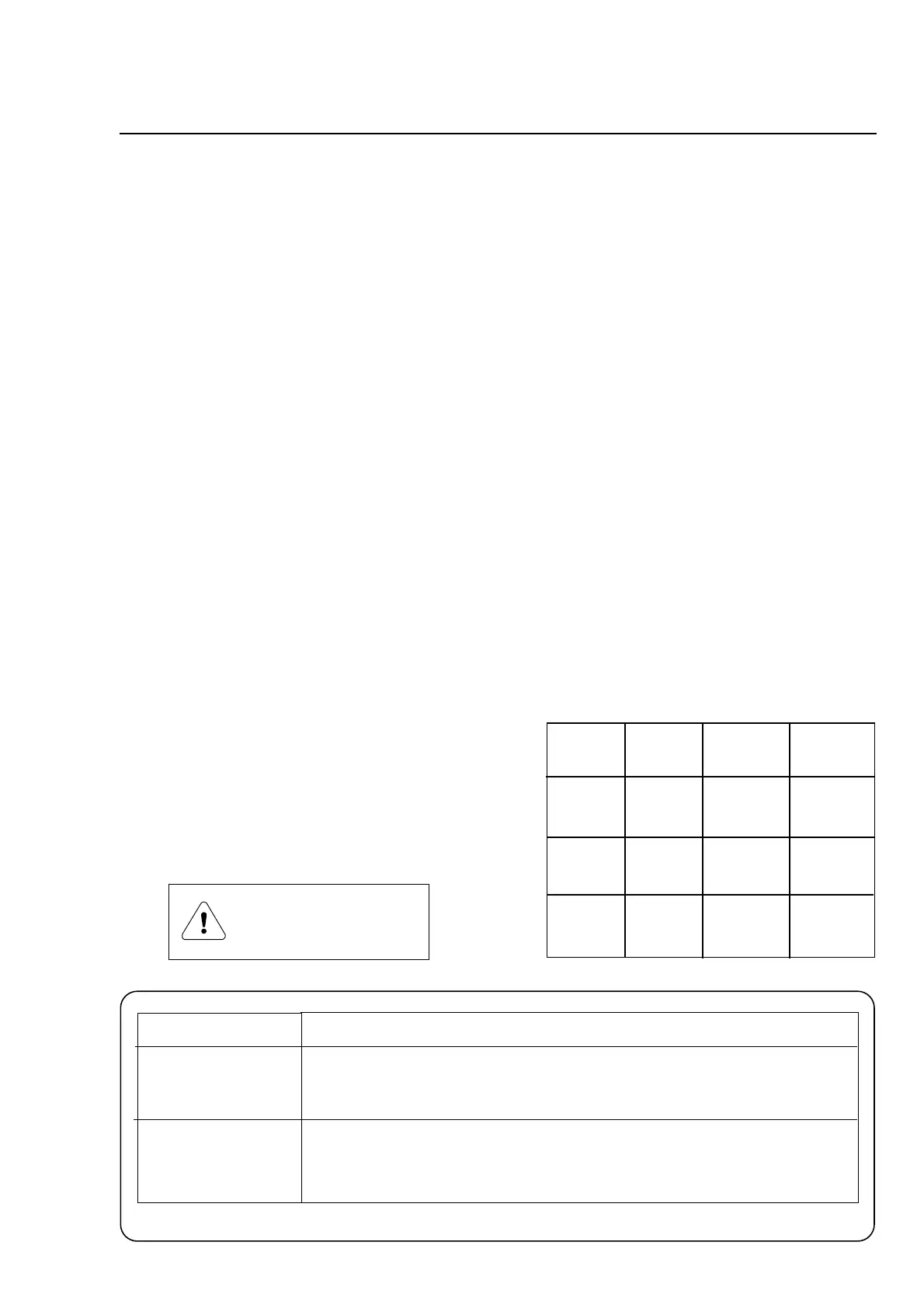

The table below shows the exhaust duct diameter and the

necessary fresh-air inlet area.

Note! It is recommended that each dryer is connected to a

separate exhaust duct.

The exhaust duct

diameter must not

be reduced.

12345678910

7

3

/4” 11” 12

3

/8” 14” 15

3

/4”17

3

/4”18

3

/4”19

5

/8”21” 22”

(200) (280) (315) (355) (400) (450) (475) (500) (535) (560)

1

5

/8 3

1

/4 4

7

/8 6

1

/2 8

1

/16 9

5

/8 11

5

/16 13 14

1

/2 16

1

/8

(0.15) (0.35) (0.45) (0.60) (0.75) (0.90) (1.05) (1.20) (1.35) (1.50)

Number of tumble

dryers

Exhaust duct

diameter, inches

(mm)

Required area of

fresh-air inlet, square

feet (minimum)

(m

2

)

Each machine requires a 15

3

/4”x 15

3

/4” fresh-air inlet opening. (400 x 400 mm)

With With With

1 elbow 2 elbow 3 elbow

Type 30 30 ft 24 ft 18 ft

Type 50 30 ft 24 ft 18 ft

Type 75 100 ft 94 ft 88 ft

Loading...

Loading...