Installation manual

37

487 14 59 11 - TD30 TD50 TD75 US

Gas installation general

Install a manual gas shutoff valve upstream from

the dryer.

The gas connection to the dryer should be

dimensioned to an output depending upon the kW-

rating of the dryer.

The factory nozzle pressure setting must

correspond to the fuel value given on the data

label.

Check that the nozzle pressure and fuel value

correspond with the values in the gas tables on the

following pages. If not, contact the supplier.

Bleed the pipe system before connecting the

machine.

After connection, test all joints for leaks.

The dryer and its individual shutoff valve must be

disconnected from the gas supply piping system

during any pressure testing of the system at test

pressures in excess of 1/2 psig (3.5 kPa).

The dryer must be isolated from the gas supply

piping system by closing its individual manual shut-

off valve during any pressure testing of the gas

supply piping system at test pressures equal to or

greater than 1/2 psig (3.5 kPa).

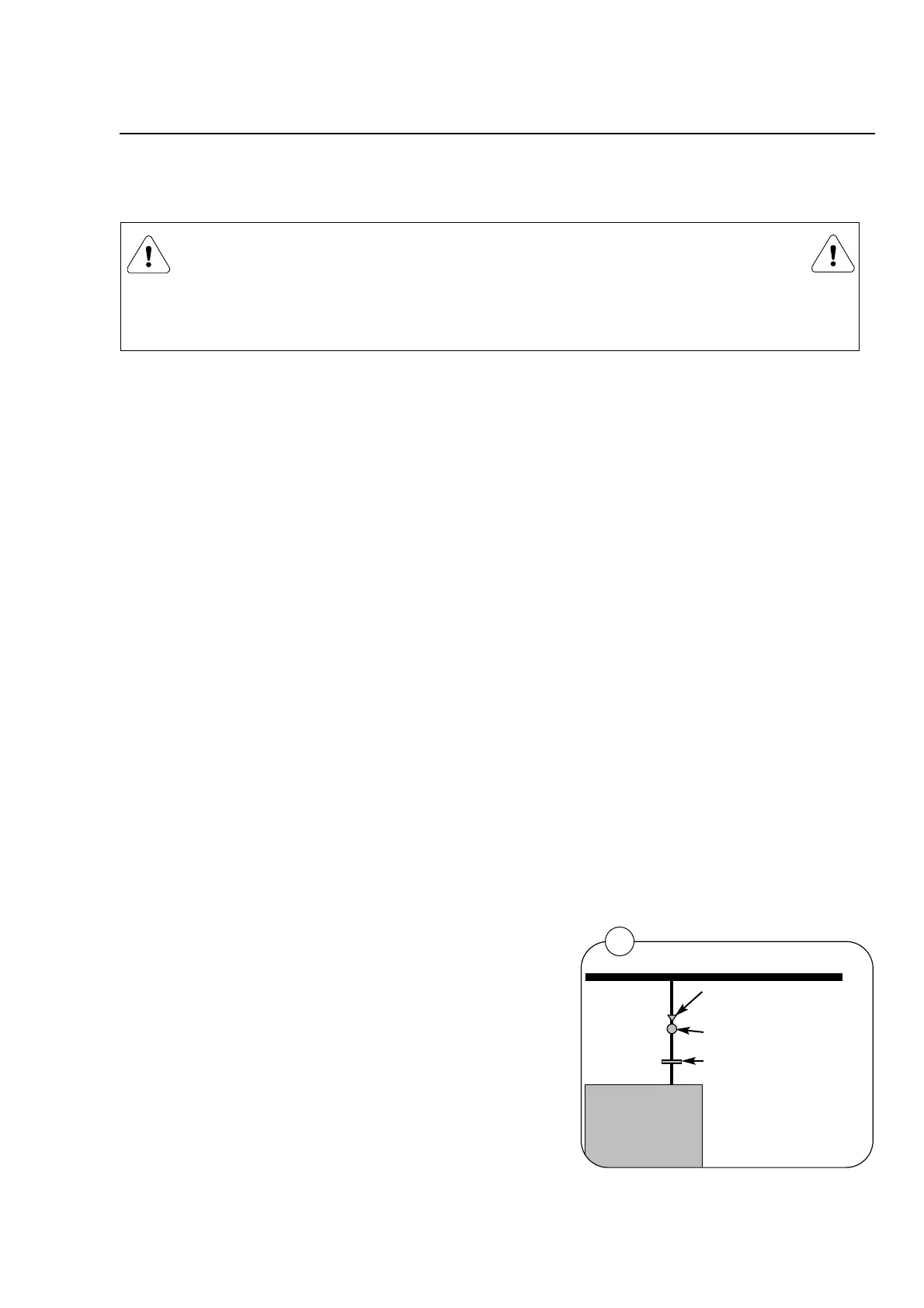

Fig.1 A minimum

1

/

8

inch NPT plugged tap,

accessible for test gage connection, must be

installed immediately upstream from the gas

supply connections to the dryer.

It is your responsibility to have all plumbing connections made by a qualified

professional to insure that the gas plumbing installation is adequate and conforms

with local and state regulations or codes. In the absence of such codes, ALL

plumbing connections, material, and workmanship must conform to the applicable

requirements of the National Fuel Gas Code ANSI Z223.1-LATEST EDITION or

the CAN/CGA-B149, INSTALLATION CODES - both the latest edition.

1

Pressure regulator

(optional) propane only

Gas shutoff valve

1

/

8

” NPT plugged tap

Loading...

Loading...