C-10 Solvent Considerations

Vacuum Degassing

The longer the solvent is exposed to the vacuum, the more dissolved gases are

removed. Two factors affect the amount of time the solvent is exposed to the

vacuum:

• Flow rate – At low flow rates, most of the dissolved gas is removed as the

solvent passes through the vacuum chamber. At higher flow rates, lesser

amounts of gas per unit volume of solvent are removed.

• Surface area of the degassing membrane – The length of the degassing

membrane is fixed in each vacuum chamber. To increase the length of

membrane, you can connect two or more vacuum chambers in series.

The in-line degasser is available as an option or factory-installed in the

Waters

®

2695 Separations Module, XE model.

Wavelength selection

This section includes UV cutoff ranges for

• common solvents.

• common mixed mobile phases.

• chromophores.

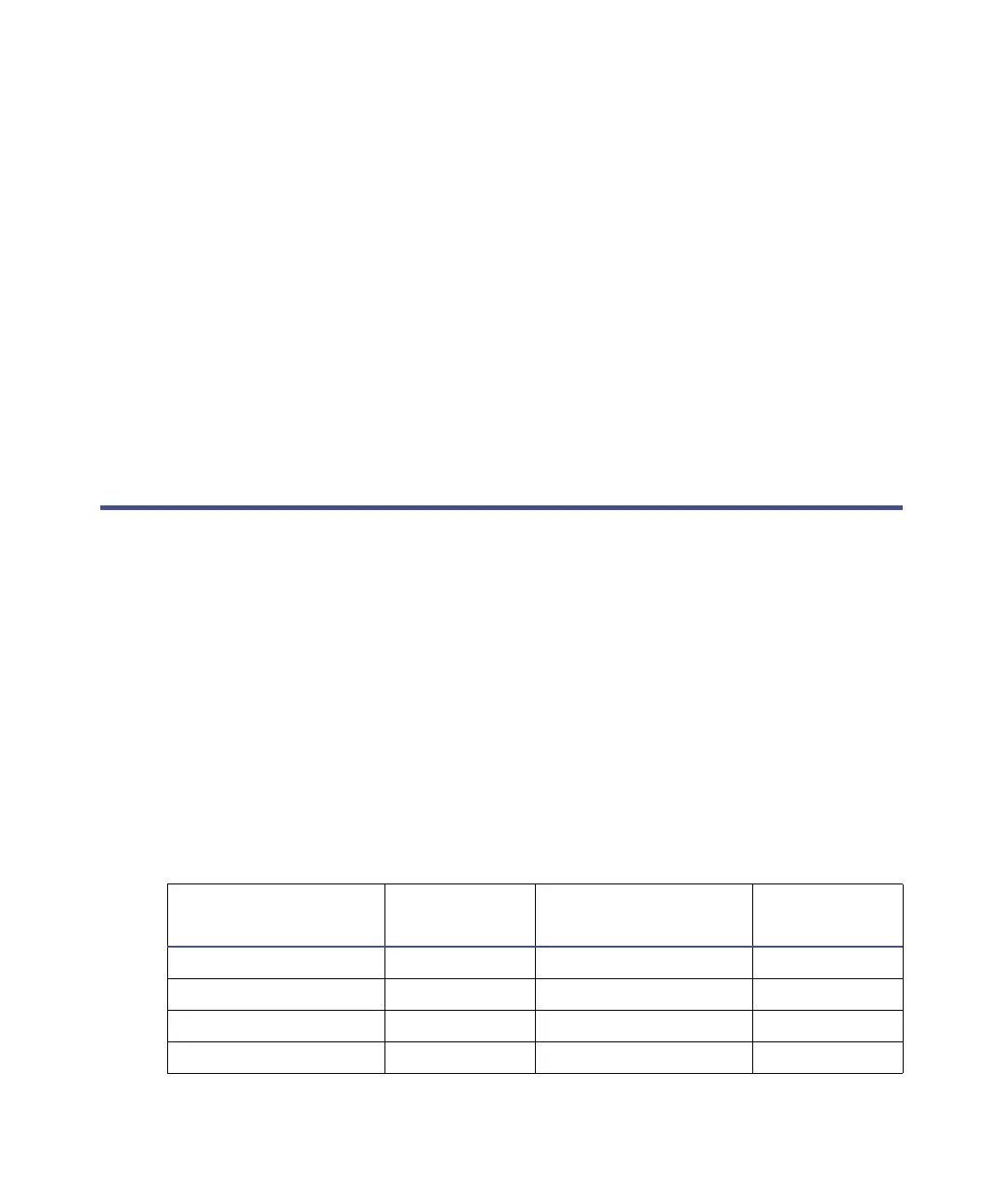

UV cutoffs for common solvents

The table below shows the UV cutoff (the wavelength at which the absorbance

of the solvent is equal to 1 AU) for some common chromatographic solvents.

Operating at a wavelength near or below the cutoff increases baseline noise

because of the absorbance of the solvent.

UV cutoff wavelengths for common chromatographic solvents

Solvent

UV Cutoff

(nm)

Solvent

UV Cutoff

(nm)

1-Nitropropane 380 Ethylene glycol 210

2-Butoxyethanol 220 Iso-octane 215

Acetone 330 Isopropanol 205

Acetonitrile 190 Isopropyl chloride 225

Loading...

Loading...