Maintenance schedule

January 11, 2016, 715004599 Rev. B 91

Maintenance schedule

The following table lists periodic maintenance schedules that ensure optimum instrument

performance.

The maintenance frequencies shown apply to instruments that normally receive moderate

use.

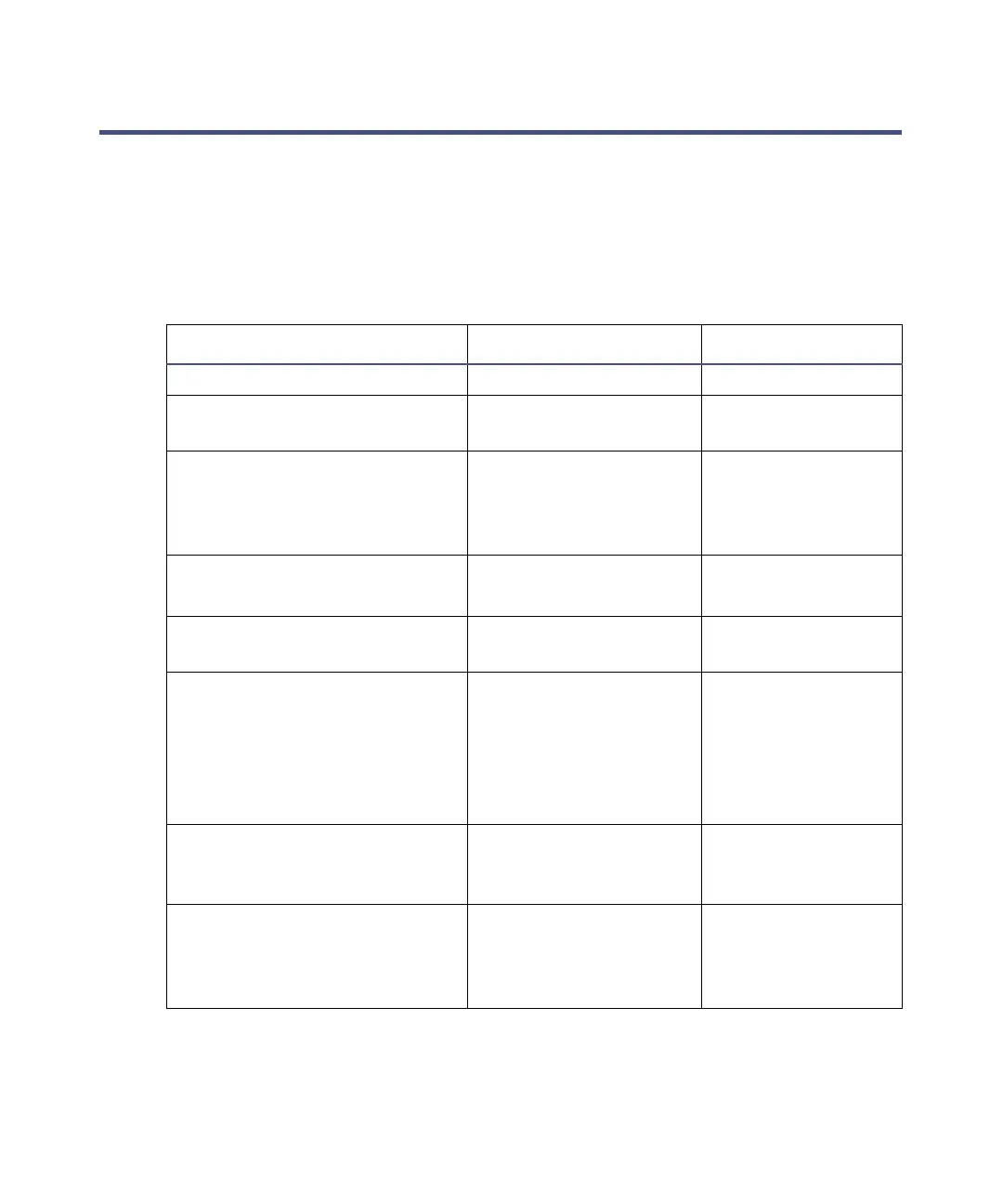

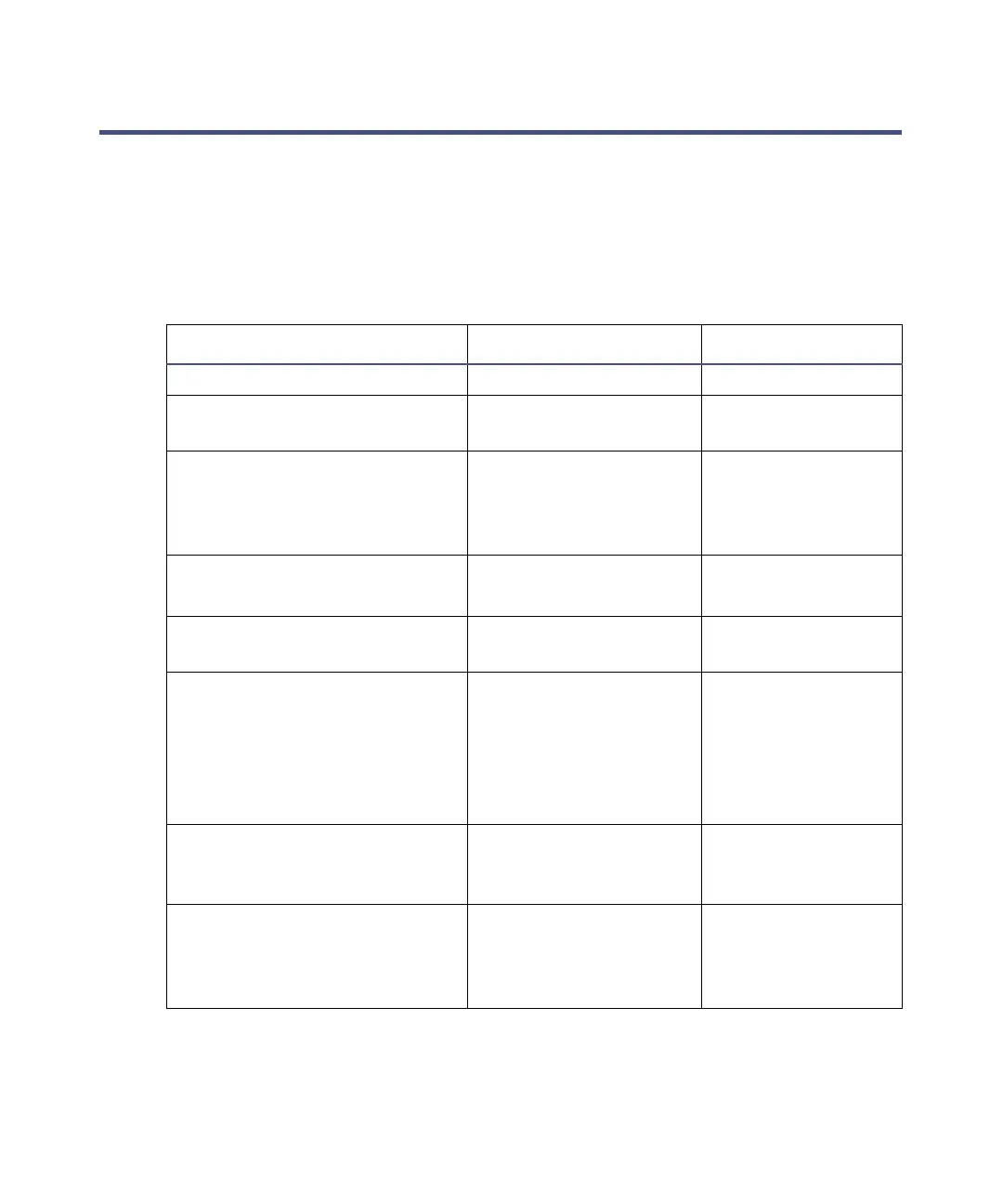

Maintenance schedule:

Procedure Frequency For information...

Clean the instrument case. As required. See page 108.

Empty the exhaust trap bottle in

the instrument exhaust line.

Check daily, empty as

required.

See page 108.

Replace the oil-free (scroll)

pump’s seals.

Annually. See Edwards

document XDS35i

Instruction Manual

A730-01-880.

Gas ballast the roughing pump. ESI – weekly. See page 110.

Inspect and adjust the roughing

pump oil level.

Weekly. See page 112.

Clean the source components. When they are visibly

fouled, the background or

high-peak contaminants

are unacceptably high, or

sensitivity decreases to

unacceptable levels.

See page 114.

Clean or replace the ESI probe tip. When sensitivity

decreases to unacceptable

levels.

See page 184.

Replace the ESI probe capillary. When sensitivity

decreases to unacceptable

levels or sample flow is

inconsistent.

See page 150.

Loading...

Loading...