USER manual

56 of 216

NERO

C:0 M:0 Y:0 K:100

ROSSO

C:0 M:100 Y:100 K:0

VERDE

C:100 M:0 Y:100 K:0

Problem Cause Action

THE MOTOR STOPS SUDDENLY OR THE

THERMAL PROTECTOR INTERVENES

DUE TO OVERLOAD

Pump malfunction.

Turn o the machine and request the Technical

Assistance.

THE PUMP FUNCTIONS BELOW

NOMINAL CAPACITY

Pump malfunction.

Turn o the machine and request the Technical

Assistance.

THE PUMP IS NOISY Pump malfunction.

Turn o the machine and request the Technical

Assistance.

Problems highlighted in grey require that the machine be switched

o and the Manufacturer’s Qualied Technician be called.

7.5 Cleaning operations

7.5.1 General instructions

For perfect hygiene and eciency of the unit, a few

simple cleaning tasks are required. The indications given

here are applicable for normal use of the coee machine.

If the machine is used continuously, then cleaning should

be performed more frequently.

Do not use alkaline detergents, solvents, alcohol or aggressive

substances. The used products/detergents have to be suitable for

this purpose and must not corrode the materials of the hydraulic

circuits.

Do not use abrasive detergents which may scratch the surface of

the body.

Always use perfectly clean and hygienic cloths for cleaning.

For washing the lters, lter holders and all machine components,

use detergents supplied by the Manufacturer or specic products

for cleaning professional coee machines.

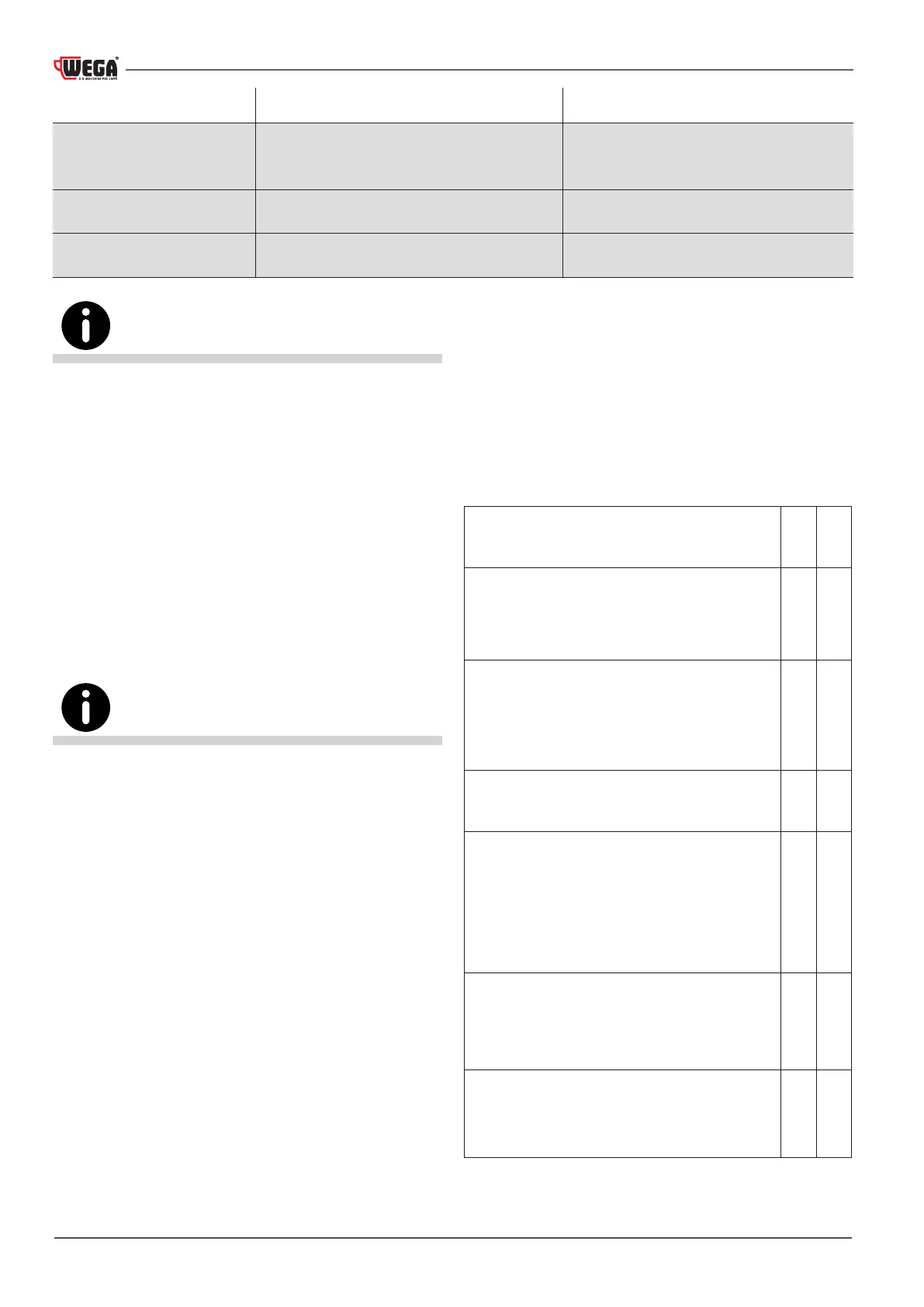

Cleaning

Daily

Weekly

Cappuccino maker:

Clean at least once a day or more often in the case of a

continued use of the cappuccino maker, following the

instructions of par. 7.5.2 on page 57.

X

Body and Grilles:

Clean the panels of the body with a cloth dampened in

lukewarm water.

Remove the drip tray and cup holder grille and wash with

hot water.

X

Filter and lter holder:

Wash the lters and lter holders daily and weekly, as

indicated in par. 7.5.3 on page 57.

X X

Steam spout:

Keep the nozzle clean at all times using a cloth dampened

in lukewarm water.

Check and clean the terminals of the nozzle, clearing out

the steam outlet holes with a small needle.

Weekly wash as described in par. 7.5.7 on page 58.

X X

Dispensing group:

Wash the dispensing unit

following the instructions of par.

7.5.4 or 7.5.5.

Carry out an internal cleaning on a weekly basis as specied

in par. 7.5.6 on page 58 .

X X

Grinder-dispenser and Hopper

Clean the hopper and the dispenser inside and out with a

cloth dampened with warm water.

When nished, dry all parts thoroughly.

X

Loading...

Loading...