25

Technical manual

ENGLISH

NERO

C:0 M:0 Y:0 K:100

ROSSO

C:0 M:100 Y:100 K:0

VERDE

C:100 M:0 Y:100 K:0

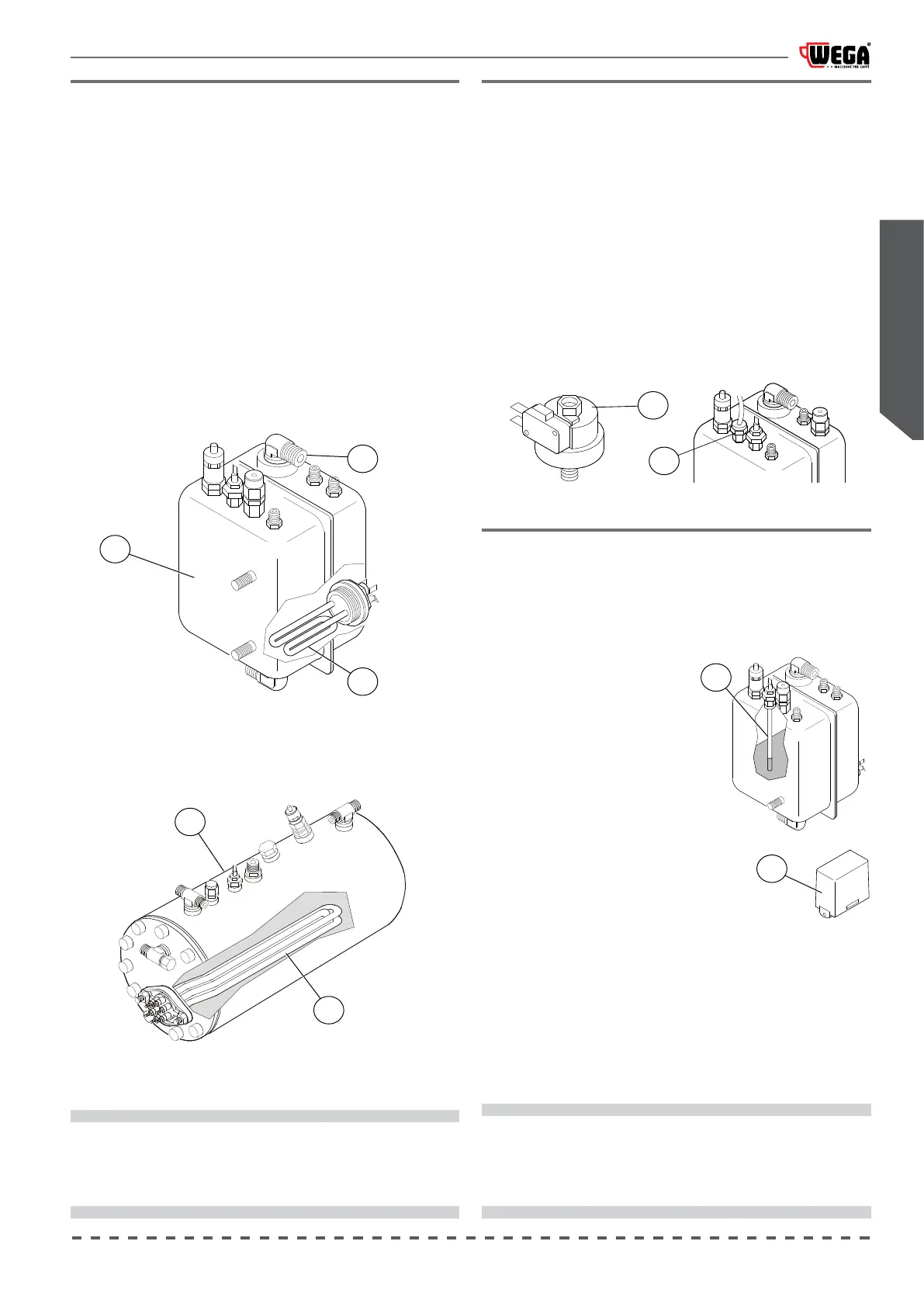

4 Boilers

The boiler is constructed in steel (1) (version 1GR)

or copper sheet metal (version 2GR) , to which the

heat exchangers (3) are assembled which in turn are

connected to the delivery group. During delivery, cold

water is sent to the inside of the exchanger by means of

the motor pump. Inside the heat exchanger, cold water

and the pre-existing hot water are mixed, thus obtaining

optimal water temperature for coee infusion.

The water is heated in the boiler by means of an

electrical heating element immerged in the water (2).

1

2

!

Do not replace thhe heating element with a higher

power one. Before making any modication contact

the manufacturer.

1

3

2

Version 1GR

Version 2GR

5

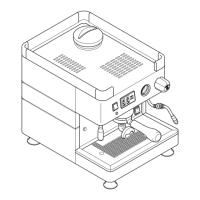

Control of the pressure in the boiler

Versions EMA - EPU:

The pressure switch (1) makes it possible to control

boiler pressure by activating or bypassing the heating

element in the boiler.

Version EVD:

The pressure in the boiler is controlled by an

appropriate NTC sensor place on the boiler (2). This

sensor continously sends information to the electronic

control unit, which as a result, active or less the heating

element by using a power triac.

1

2

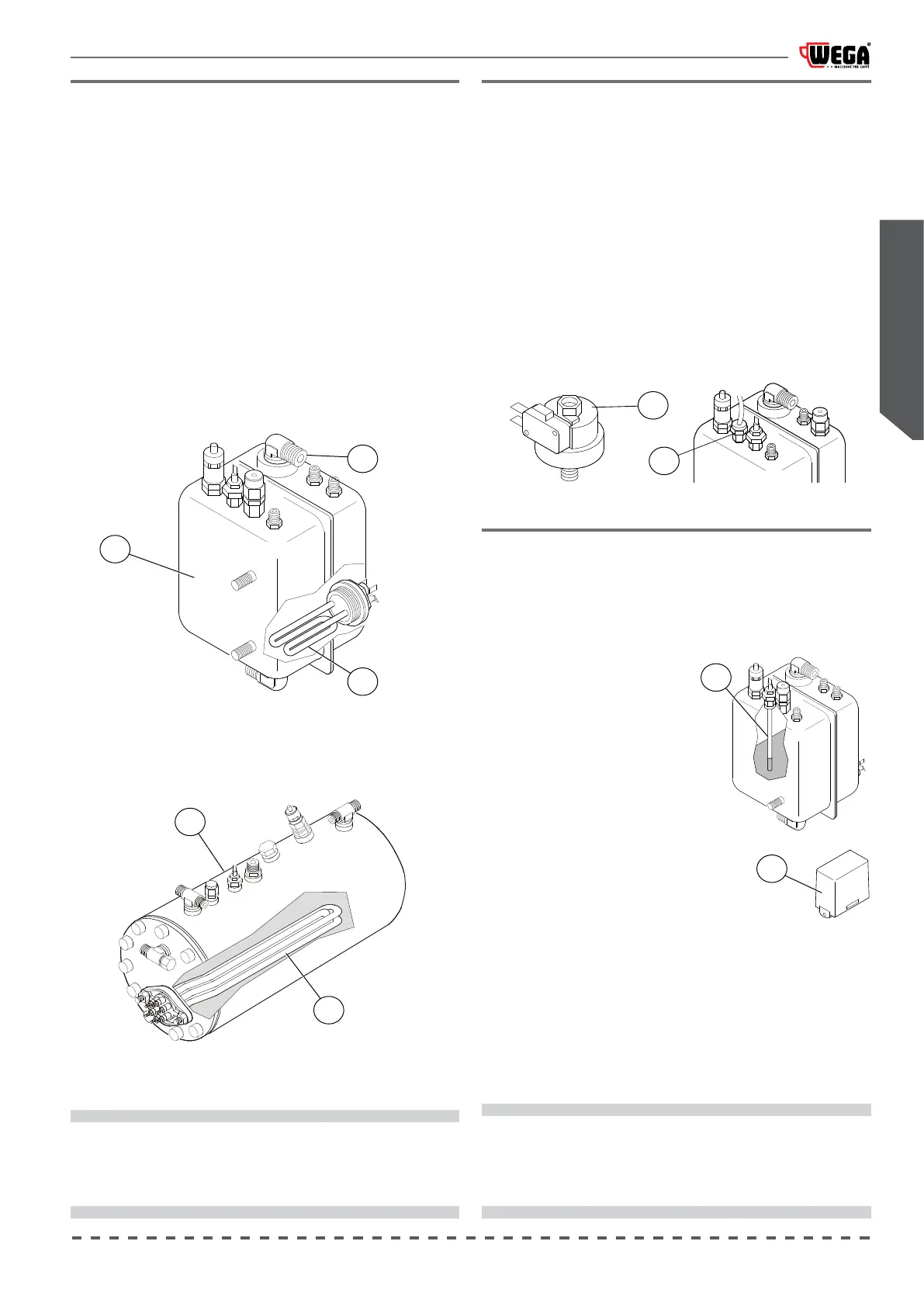

6 Automatic Water Entry

The Automatic Water Entry system is for checking the

boiler level. It is composed of:

• level probe inserted in the boiler (1) composed of a

stainless steel rod;

• electronic control unit (2);

• the pump allows the raising

of the pressure of the inow

water at a pressure of 8-9 bar

for the delivery.

The electronic control unit

controls the water level in the

boiler. When the water level

drops down, the contact with

the probe is interrupted, the

electronic control unit sends

a signal to the lling solenoid

valve, which activates the motor pump and the lling

solenoid valve, thus restoring the level of water in the

boiler.

To avoid possible flooding due to machine

malfunctions or leaks in the hydraulic circuit, the

electronic control unit includes a timing device

“Time-out” that cuts off automatic filling after a

maximum operating time (2 minutes).

!

In versions with the inner tank, the water lack is reported,

in version EVD by the ashing of led STOP/PROG. of the

push button panel or by the specic warning light in

versions EMA-EPU.

1

2

Loading...

Loading...