27

Technical manual

ENGLISH

NERO

C:0 M:0 Y:0 K:100

ROSSO

C:0 M:100 Y:100 K:0

VERDE

C:100 M:0 Y:100 K:0

11 Electronic push button panels

(version EVD)

The electronic push button panel of the machine

permitt selection and programmation of coee doses.

They are connected to the electronic control unit.

To use and programming see the user's manual of

the specic model.

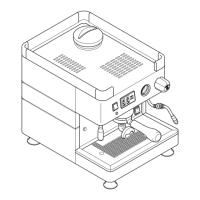

12 Pressure switch

The pressure switch makes it

possible to control boiler pressure

by activating or bypassing the

heating element in the boiler.

Any calibration of the pressure

switch which may be required can

be carried out with the machine in

operation by means of the screw

(6)

located on the body of the component.

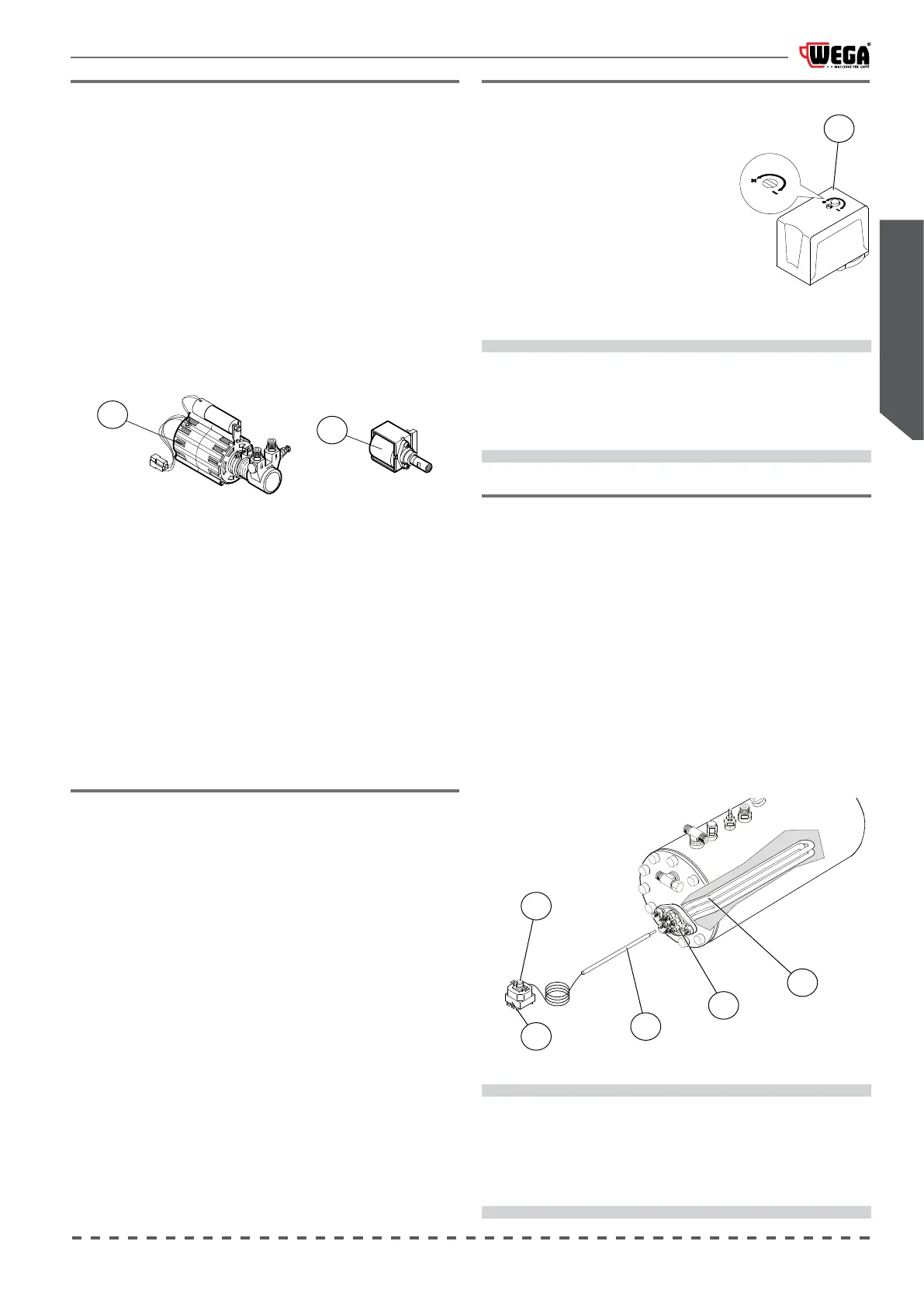

13 Thermostat

IlThe thermostat allows you to avoid damage to the

electrical resistance in case of lack of water in the boiler.

The thermostat bulb (7) is located inside a sheath (8)

placed at the center of the resistance. The contacts of the

thermostat (9) are connected to the electrical resistance

(10). If the resistance is exposed due to failure to load

water to the boiler, the temperature of the resistance

increases dramatically. At this point, the thermostat

interrupts the power supply to the resistance thus

preventing damage.

6

8

10

7

11

9

!

The internal contacts of the pressure switch may

be subject to oxidation. It is recommended to

clean the contacts regularly spraying them with

antioxidants.

!

To reset the thermostat, press the central button

(11). However, before trying to operate the

machine, verify the causes of the blockade of the

water feeding boiler.

10 Pumping system

This is a component that feeds the machine, raising

the water pressure to 8-9 bar for coee delivery and

automatic lling of the boiler

.

Depending on the whether the machine is equipped

with an inner tank, or connection to the aqueduct, it

changes, having supplied:

• motorpump

(1), in the versions with connection to the

water network;

• vibration pump (2) in the versions with inner tank.

2

1

Loading...

Loading...