Pre-Installation

Greenstar 8000 Life – 6720883866 (2019/04)

10

[13] Ignition electrodes

[14] Flame sensing electrode

[15] Flow temperature sensor at flow pipe

[16] Heating block temperature limiter

[17] Flow temperature sensor at heating block

[18] Inspection cover

[19] Condensate sump

[20] Gas valve

[21] Drain point

[22] Control unit

3.9 Product data for energy consumption

The product data on energy consumption can be found in the operating

instructions for the user.

4 Pre-Installation

NOTICE:

Risk of damage to system or appliance!

Before installation

▶ All the following Pre-Installation sections must be read and

requirements met before starting appliance or flue installations.

4.1 System preparation

4.1.1 Artificially softened water

It is possible to have an ion exchange water softener fitted to the cold

water system of the property. However, the appliance requires an

untreated cold water connection taken from the mains supply, before the

water softener, to the primary water filling point of the heating system.

Alternatively there are water softening/treatment appliances that do not

adjust or alter the pH levels of the water. With these appliances it may not

be necessary to provide an untreated water by-pass to the primary water

filling point of the heat system.

NOTICE:

▶ Salt based softened water must not be used to fill the central heating

system.

4.1.2 Water systems and pipe work

Primary system plastic pipework:

• Any plastic pipe work must have a polymeric barrier, complying with

BS 7921 and installed to BS 5955 with 600mm (minimum) length of

copper connected to the appliance.

• Plastic pipe work used for under-floor heating must be correctly

controlled with a thermostatic blending valve limiting the

temperature of the circuits to approximately 50°C with 1000mm

(minimum) length of copper or steel pipe connected to the

appliance.

Primary system/connections/valves:

• Do not use galvanised pipes or radiators.

• All system connections, taps and mixing valves must be capable of

sustaining a pressure of 3 bar.

• Radiator valves should conform to BS 2767:10.

• All other valves should conform to BS 1010.

• It is best practice to fit Thermostatic Radiator Valves (TRV's) to all

radiators, except the area where the room thermostat is sited which

must be fitted with lockshield valves that are left open.

• If the circulating pump speed is fixed and system circulation can be

significantly adjusted or stopped by TRV's or zone valves, a system

bypass should be installed to give at least a 3 metre circuit when

activated. However; any appliance fitted with a modulating pump

may not require a system bypass.

• Drain cocks are required at all the lowest points on the system.

• Air vents are required at all high points on the system.

Primary system considerations - Regular appliances

Open vent

• Close Coupled feed and expansion arrangement:

– The open vent pipe and feed and expansion pipe must rise

continuously from the appliance and be a maximum of 150mm

apart.

– The feed and expansion cistern must be positioned to provide a

minimum static head of 250mmabove the highest point in the

heating system to the water level in the feed and expansion

cistern.

– Ensure adequate space is left in the expansion cistern for

expansion of the system water.

• No valve shall be fitted in the open vent pipe or the feed and

expansion pipe.

• The open vent pipe must be at least 22mmØ.

• The feed and expansion pipe must be at least 15mmØ.

Sealed system (appliance converted to operate on a sealed system)

• The CH sealed system must be filled using a WRAS approved filling

loop or comply with examples in 4.1.4 "System fill" section.

• An expansion vessel, of a size suitable for the system, must be fitted

as close as possible to the appliance in the central heating return.

• Also fit a pressure gauge, a 3 bar pressure relief valve and stop cock

(fixed cylinder type or sealed system approved connection).

• No valve shall be fitted that can isolate the appliance from the

expansion vessel or pressure relief valve.

• An automatic air vent must be fitted.

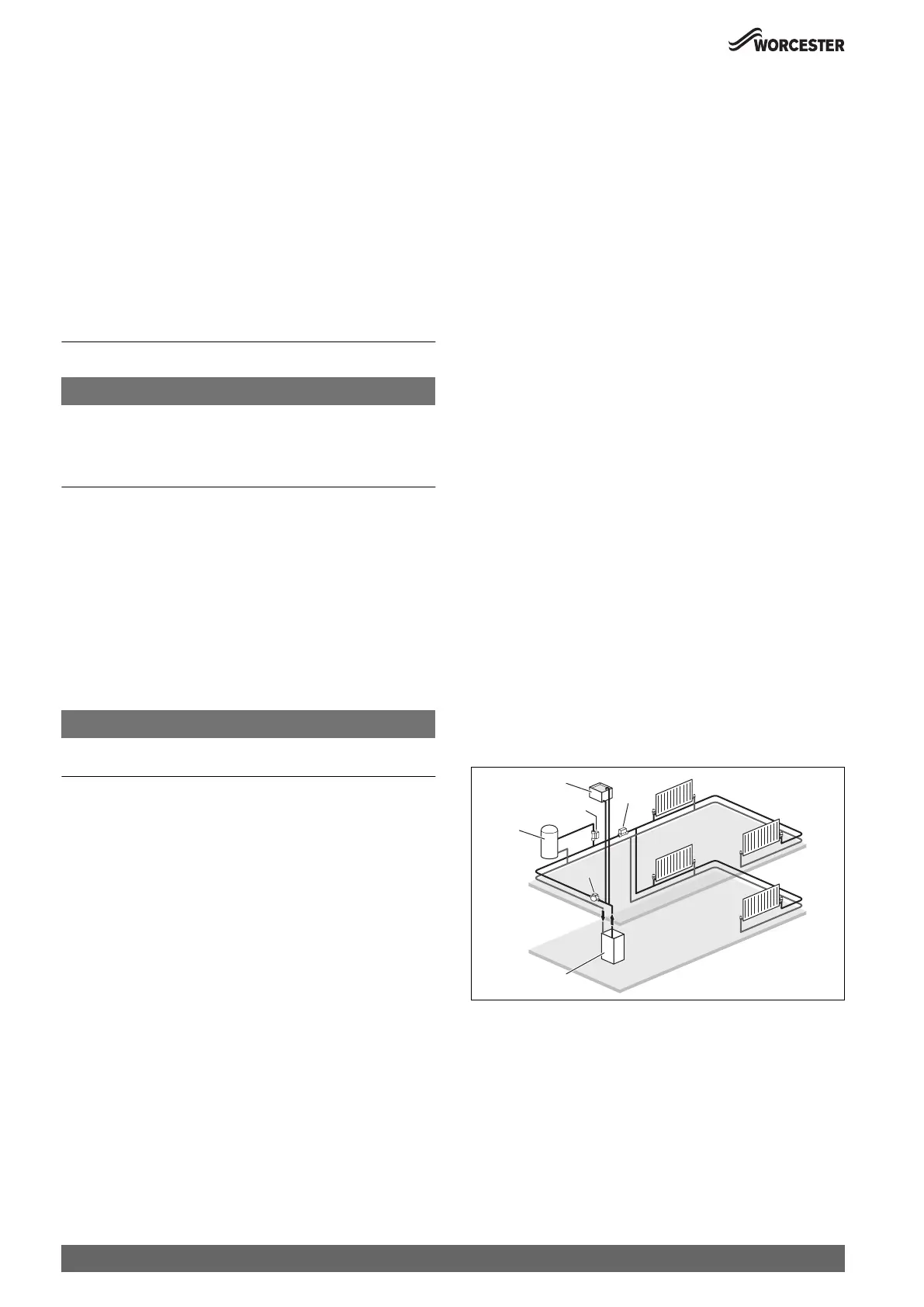

4.1.3 System layouts examples

Open vent primary system - Cylinder and central heating zone:

Typical S-Plan example

• The cylinder return must be the last connection on the common

return pipe to prevent reverse circulation.

Fig. 4 Cylinder and heating zone

[1] Appliance

[2] Zone valves

[3] Domestic hot water cylinder

[4] Circulation pump

[5] Feed and expansion tank

1

4

2

2

3

5

0010021234-001

Loading...

Loading...