Commissioning

37

Greenstar 8000 Life – 6720883866 (2019/04)

5.5.2 Cable preparations

NOTICE:

Damage to control unit!

Small pieces of wire can cause shorts and damage to electronics.

▶ When stripping wires always ensure copper strands do not fall into

the control box.

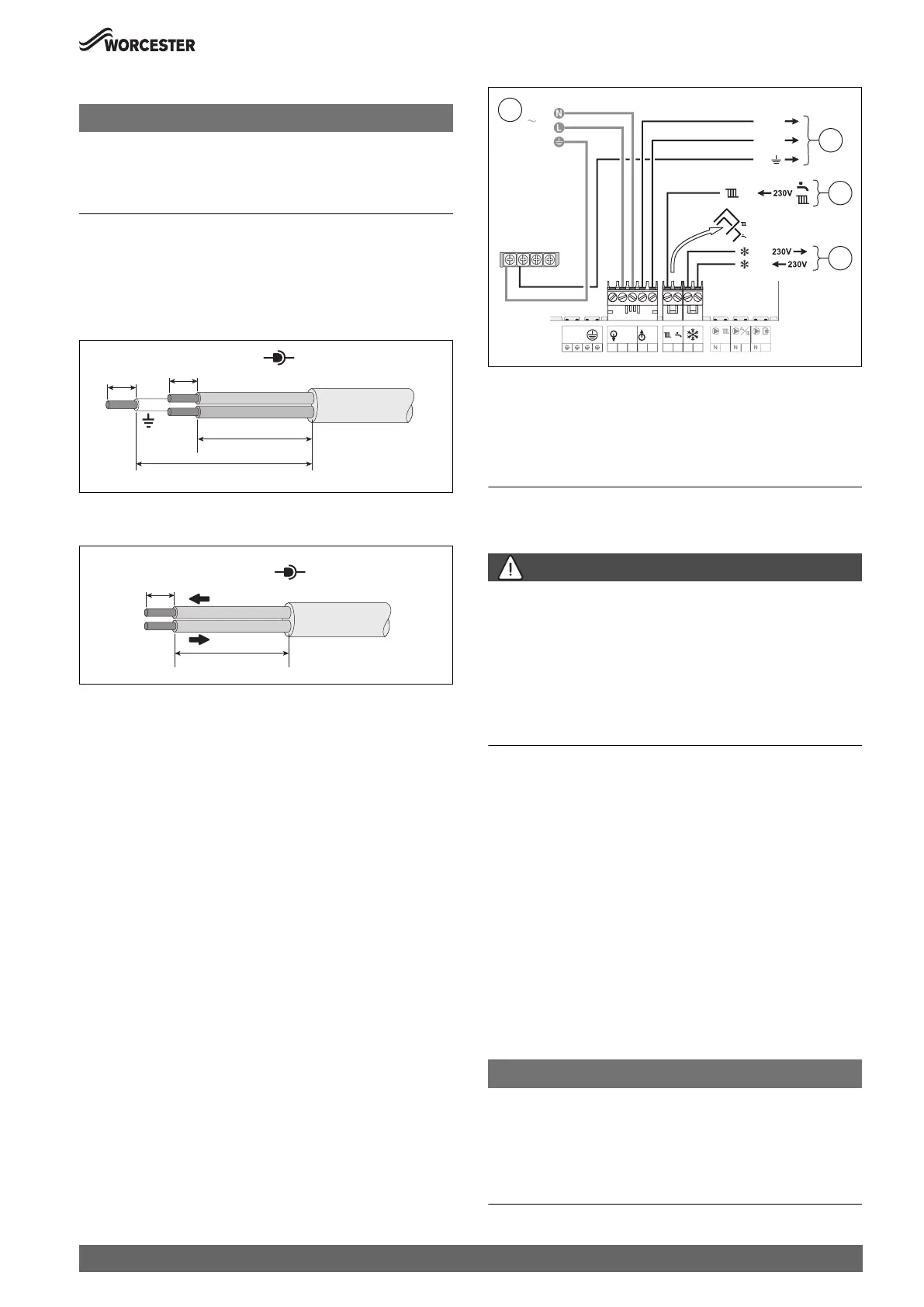

Mains voltage (power cables), example figure 55

▶ Ensure the conductors (C) can reach the appropriate terminal

connection and that the protective (earth) conductor is longer than

the other wires.

– Power cables connected to the appliance my have different

conductor lengths depending on the termination point.

Fig. 55 Mains voltage (power cables) preparation

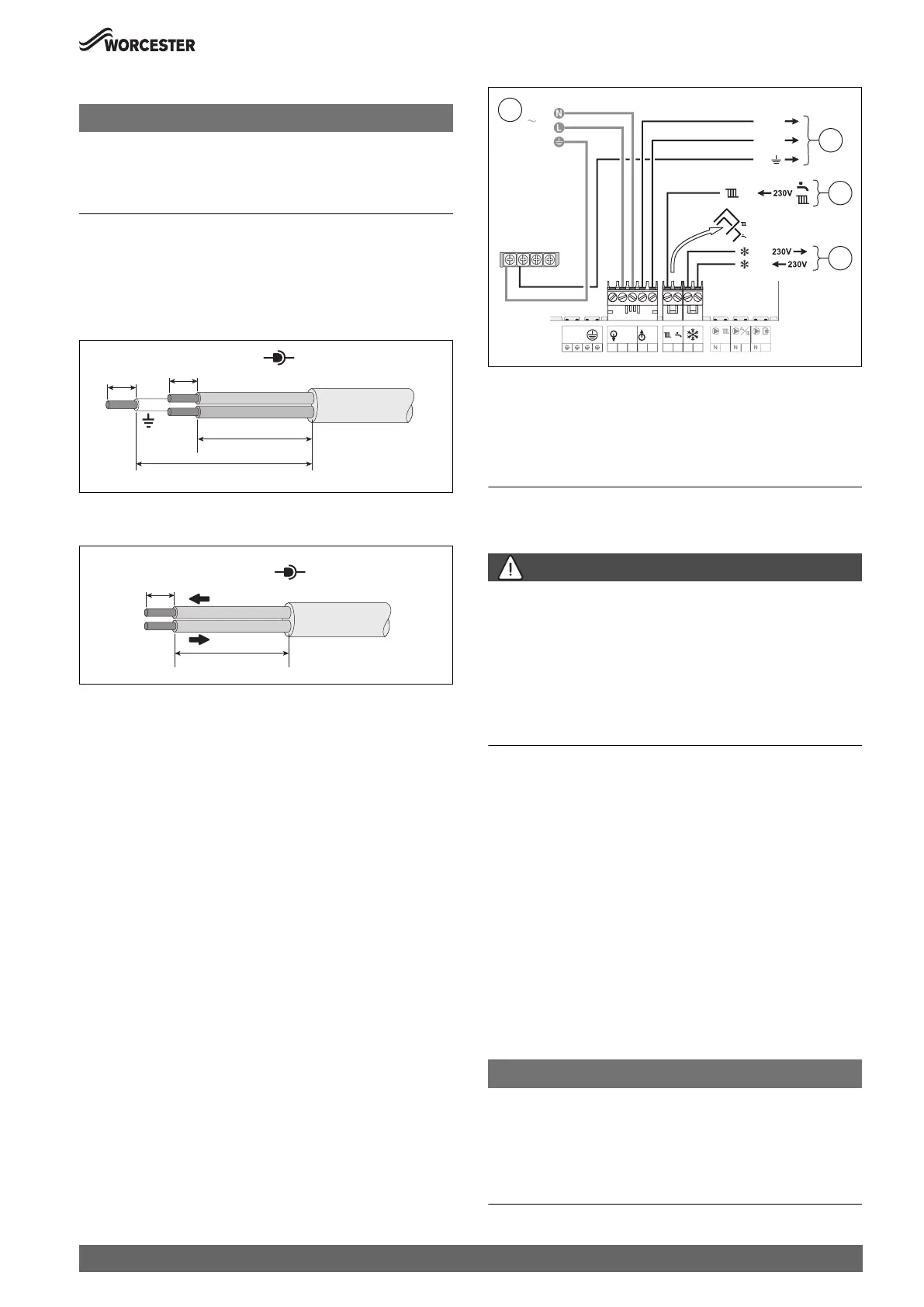

Low voltage (signal cables), example figure 56

Fig. 56 Low voltage (signal cables) preparation

5.5.3 External controls - domestic installations

Appliance external control connections example

▶ The electrical power supply to the external equipment [2] is supplied

from 230V OUT - L (Live), N (Neutral) and \ (earth) terminals.

▶ The Switch Live from the external equipment [3]:

– Both pre-wired links are removed, the CH demands are combined

and wired to the (LR terminal.

▶ External frost thermostat connections [4]:

– The Live supply is terminal FS

– The Switch Live is terminal FR

Fig. 57 External controls connections example

[1] 230V mains supply to the appliance.

[2] 230V supply from the appliance to the wiring centre.

[3] CH Switch Live (Demand) from the external controls.

[4] External frost protection Live supply and Switch Live (Demand).

6 Commissioning

6.1 Pre-Commissioning checks

DANGER:

Risk of electric shock!

▶ Isolate electrical components from the power supply (230 V AC)

(fuse, circuit breaker) and secure against unintentional re-

connection before carrying out any work.

Information on safe isolation can be found in the Health and Safety

Executive guidance HSG85.

▶ Check for zero potential before proceeding with work, using test

equipment approved to GS38 to confirm that the electricity supply is

disconnected.

Checks before commissioning:

▶ Check that the service and water pipes are connected correctly.

▶ Check the gas type specified on the identification plate matches that

of the gas supply and that the gas supply is properly purged.

▶ Appliance converted to sealed system.

– Check that the appliance is filled with water and under pressure

(1.5 bar) and that there are no leaks.

▶ Check that the electrical connections of the appliance are correct:

– Mains electrical supply - 230V, 50Hz

– Compliant earth connection

– Correct polarities.

– External equipment and controls are wired in correctly.

▶ Check that the flue is correctly fitted, airtight, free from any

obstruction and the connections are secure.

▶ Check that the condensate pipe work is connected properly and that

there are no leaks.

NOTICE:

If the appliance is not to be commissioned immediately then, after

successfully completing all of the checks and any rectification work:

▶ Isolate the electricity supply.

▶ Isolate the gas supply.

▶ Drain the system and appliance.

▶ Label appropriately.

0010023711-001

> C

C

6-8mm

6-8mm

N

L

230V

0010012956-001

26-30mm

6-8mm

0-30V

1

0010022788-001

FS

FR

PE

P

PW

FS

FR

LR

LR

PW

N

IN

230V

OUT

230V

LN

L

230V AC

LR

3

L

N

2

4

230V OUT

Loading...

Loading...