Inspection and maintenance

53

Greenstar 8000 Life – 6720883866 (2019/04)

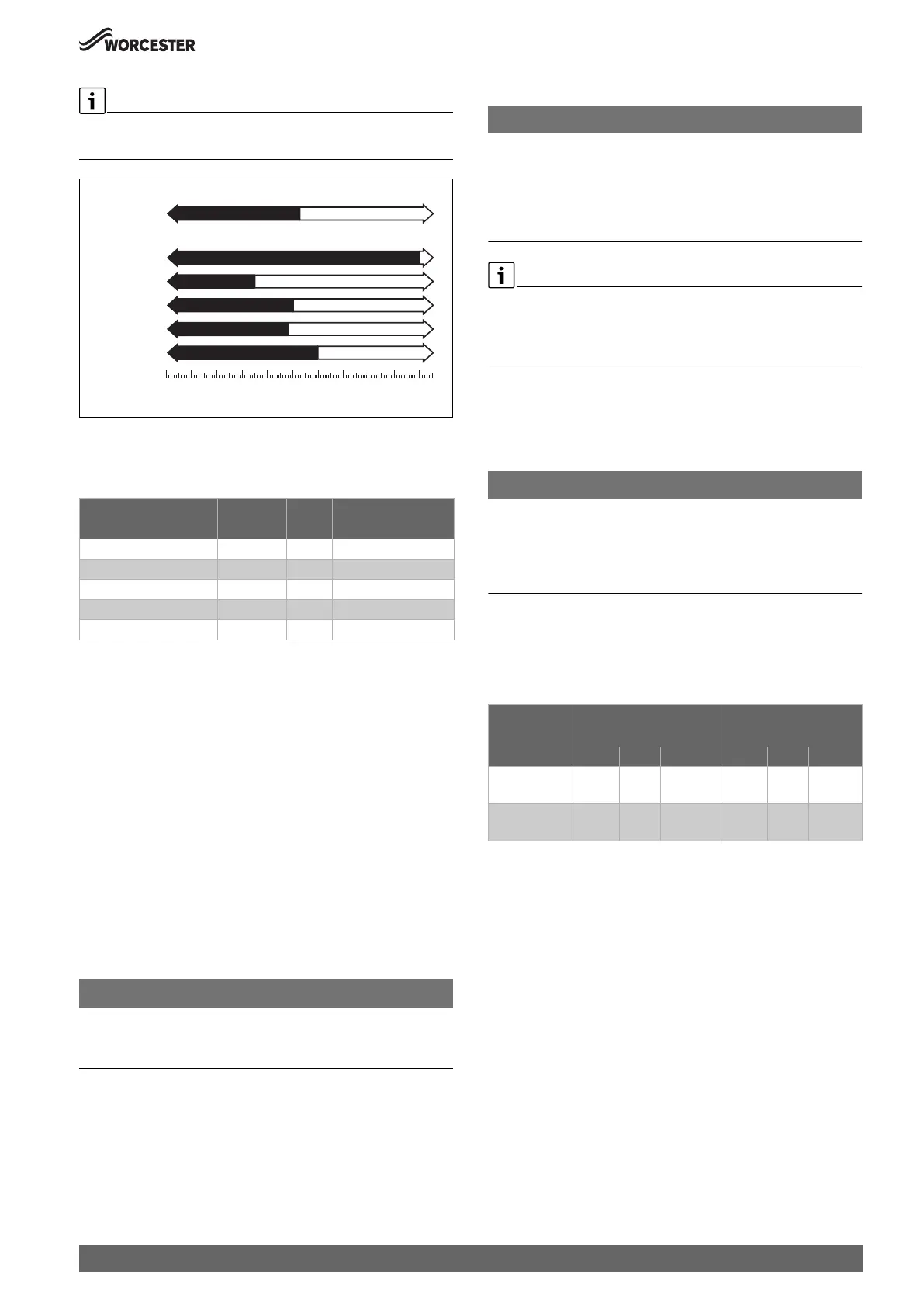

Fan pressure test reading.

▶ The pressure reading will be in negative values.

Fig. 71 Fan pressure test values

Appliance fan pressure test values

Natural Gas and LPG appliances

Table 24 Natural Gas and LPG appliances

[] Cleaning required

[] No cleaning required

If the manometer reading is higher then the appliance output value

[P] mbar.

▶ The heat exchanger/exhaust path/siphon does not require attention.

If the manometer reading shows the heat exchanger requires

cleaning, then carry out the following checks.

▶ Check that the siphon is not restricted or blocked.

▶ Check the exhaust paths for restrictions.

▶ Clean the heat exchanger with a suitable cleaning tool, refer to

cleaning section.

▶ Re-check the fan pressure readings.

If the boiler, after completing the above checks, fails the fan pressure

test then contact Worcester, Bosch Group for advice.

▶ Replace test point cover after completing pressure check.

8.6 Check working gas inlet pressure

NOTICE:

Gas inlet pressure

▶ Do not continue with the other checks if the correct gas inlet pressure

can not be achieved.

▶ Check the gas supply working pressures in the system conform to the

readings shown in the table shown in section 6.6 "Checking gas inlet

pressure".

8.7 Checking the flue integrity

NOTICE:

▶ Check flue joints are secure, the terminal and the terminal guard, if

fitted are clear and undamaged.

▶ Combustion testing must be carried out by a competent person.

Testing must not be attempted unless the person carrying out the

combustion check is equipped with a calibrated Flue Gas Analyser

conforming to BS 7967 and is competent in its use.

Flue gas analysis

▶ Ensure that the gas inlet pressure has been checked and is

satisfactory.

▶ Refit the test point plugs after the test has been completed.

▶ Refer to section 6.10 "Checking flue integrity" and check that the

readings conform to those given, confirming flue system and

combustion circuit are ok.

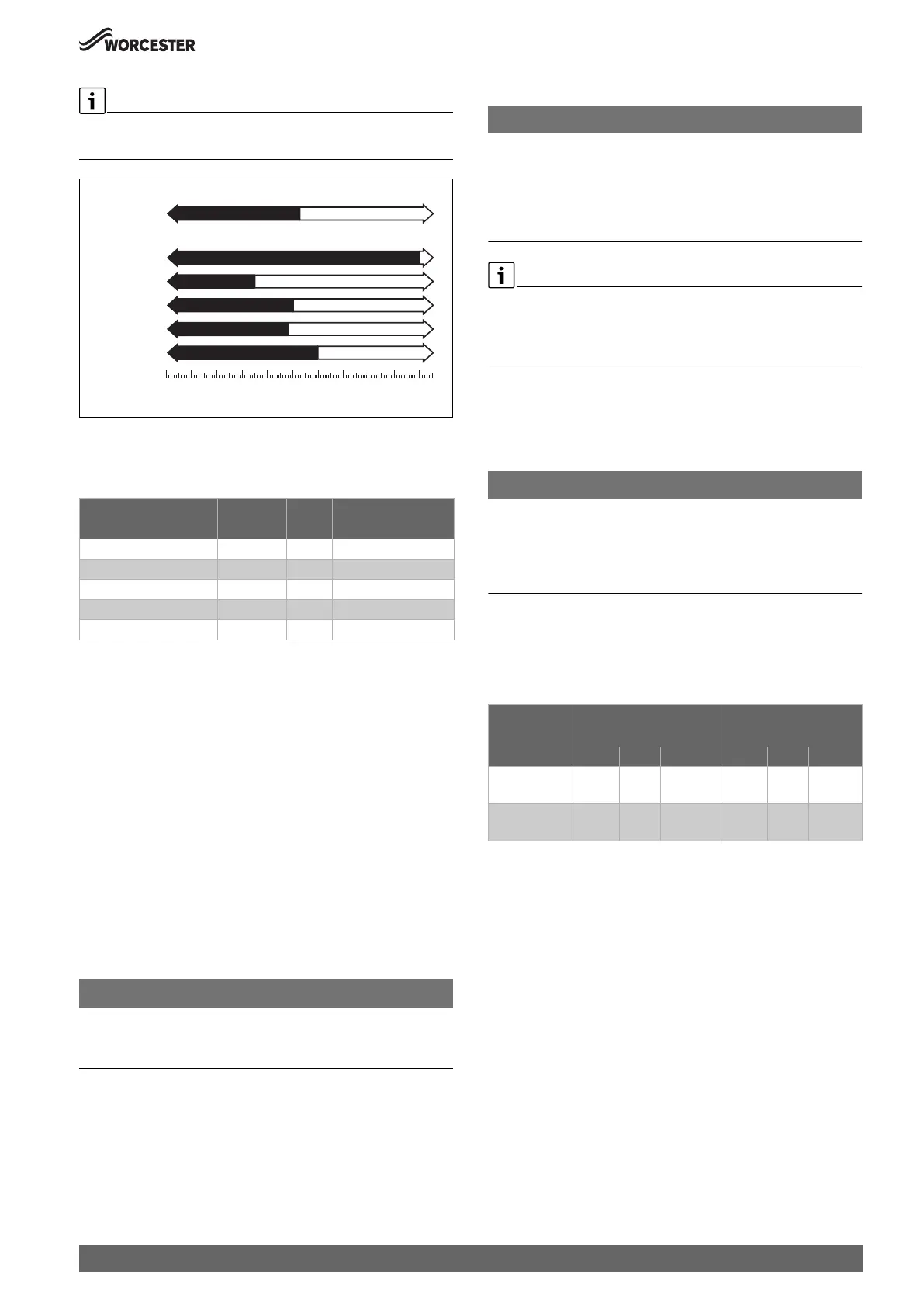

8.8 Flue gas analysis

NOTICE:

Combustion testing

▶ Combustion testing must be carried out by a competent person.

Testing must not be attempted unless the person carrying out the

combustion check is equipped with a calibrated flue gas analyser

conforming to BS 7967 and is competent in its use.

▶ Set the appliance to maximum and minimum output in chimney

sweep mode for the flue gas analysis checks ( chapter 6.4).

▶ Check that the readings conform to those given in the following

tables. In addition to CO and CO/CO

2

ratio checks also check the

maximum and minimum CO

2

percentage reading.

Table 25 CO

2

and O

2

contents

If the CO

2

is out of tolerance then please check:

▶ The gas inlet pressure.

▶ The gas rate.

▶ The fan test pressure.

▶ The flue and air intake, plus any possible blockages in the condensate

disposal.

▶ The condition of burner.

▶ For leaks or obstructions in the exhaust paths.

▶CO

2

is correctly adjusted.

The gas valve and venturi are factory set and should not need to be

adjusted, if found to be out of tolerance and when all other possible

causes have been checked, please contact the Worcester Bosch Group

Helpline 0330 123 3366.

Appliance

Value [P]

GR8300iW 30 0 mbar to -10,0 mbar

GR8300iW 35 0 mbar to -3,5 mbar

GR8300iW 40 0 mbar to -5,0 mbar

GR8300iW 45 0 mbar to -4,8 mbar

GR8300iW 50 0 mbar to -6,0 mbar

FAN PRESSURE TEST

Appliances

0

-6

-5

-4

-3

-2-1

-8

-7

-10

-9

mbar

GR8300iW 30:

- 10.0

GR8300iW 35:

- 3.5

GR8300iW 40:

- 5.0

GR8300iW 45:

- 4.8

GR8300iW 50:

- 6.0

Clean the Heat Ex. Heat Ex. ok

0010024797-001

Maximum rated output Minimum rated output

Gas type CO

2

O

2

CO CO

2

O

2

CO

Natural gas 9.5 %

± 0.4

4.0 % <250ppm 8.6 %

± 0.4

5.5 % <75ppm

Liquid

propane (LPG)

10.8 %

± 0.4

4.6 % <250ppm 10.2 %

± 0.4

5.5 % <75ppm

Loading...

Loading...