Pre-Installation

13

Greenstar 8000 Life – 6720883866 (2019/04)

4.2.2 Gas supply

• Appliances using Natural Gas (NG) must be connected to a governed

meter.

• Appliances using Liquid Petroleum Gas (LPG) must be connected to

a regulator.

• Installation and connection of the gas supply to the appliance must

be in accordance with BS6891.

• Gas pipe sizing should be calculated to ensure no more than the

permitted mbar drop between the meter/governor to the appliance

inlet. ( chapter 12.7).

• The meter or regulator and pipe work to the meter or regulator must

be checked, preferably by the gas supplier. This is to ensure that the

equipment is in good working order and can meet the gas flow and

pressure requirements, in addition to the demand from any other

appliance being served.

Pipe sizing (NG & LPG)

Gas pipe work:

▶ Gas installation pipe work must be designed to ensure the pressure

loss between the meter outlet (NG) or storage and regulator (LPG)

and the inlet to each appliance does not exceed 1mbar (NG) 2.5mbar

(LPG) table 15 ”Allowed mbar pressure drop”.

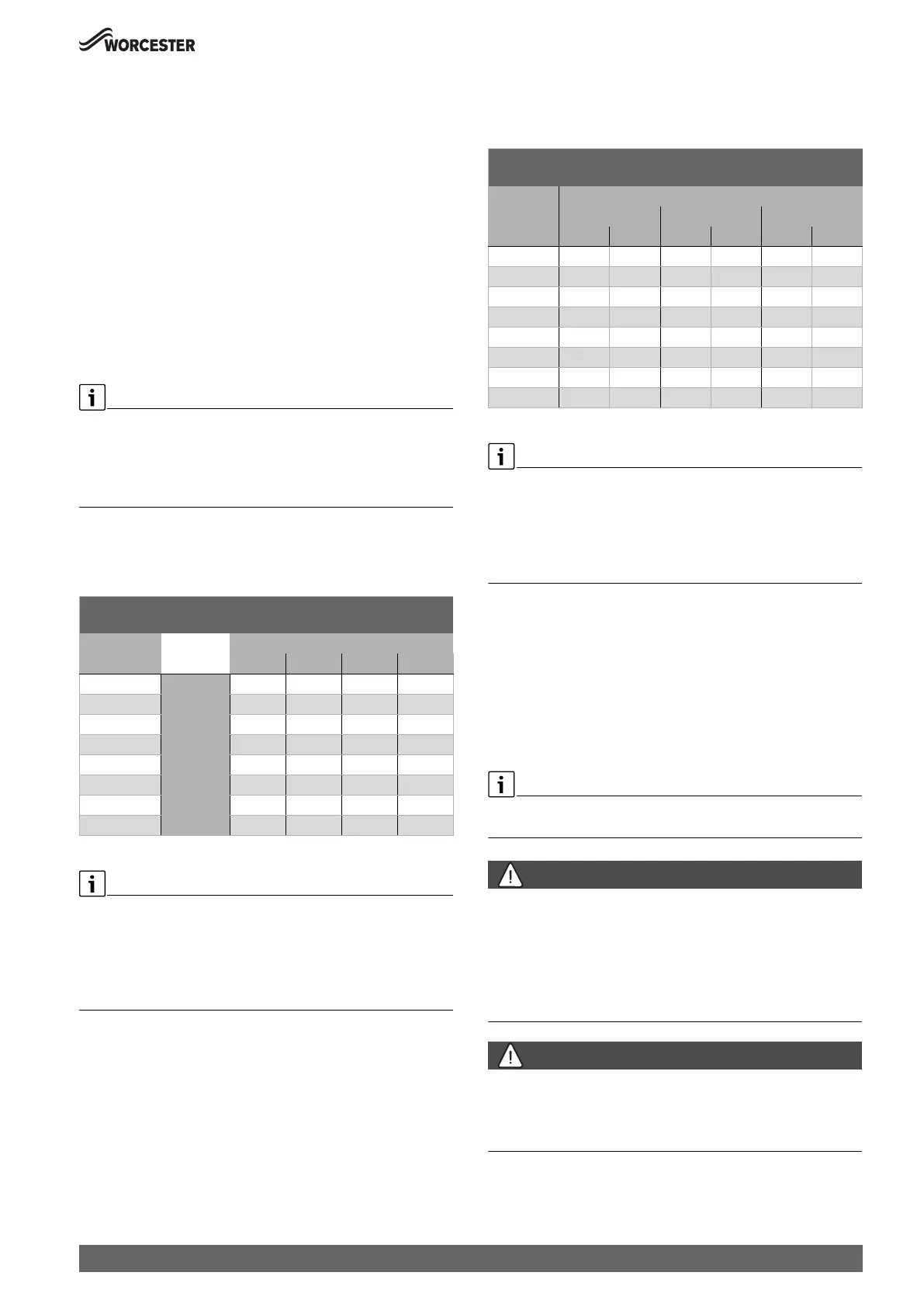

Natural Gas (NG):

Discharge rates for copper tube with 1mbar differential pressure

between the ends for Natural Gas.

Table 5 Natural Gas

Natural Gas:

▶ When using this table to estimate the gas flow rate in pipe work of a

known length, the effective length will be increased by 0.5m for each

90° elbow and tee fitted and by 0.3m for each 90° bend. This method

is only a estimate - for more complex design please refer to BS6891

2015 and training given in ACS.

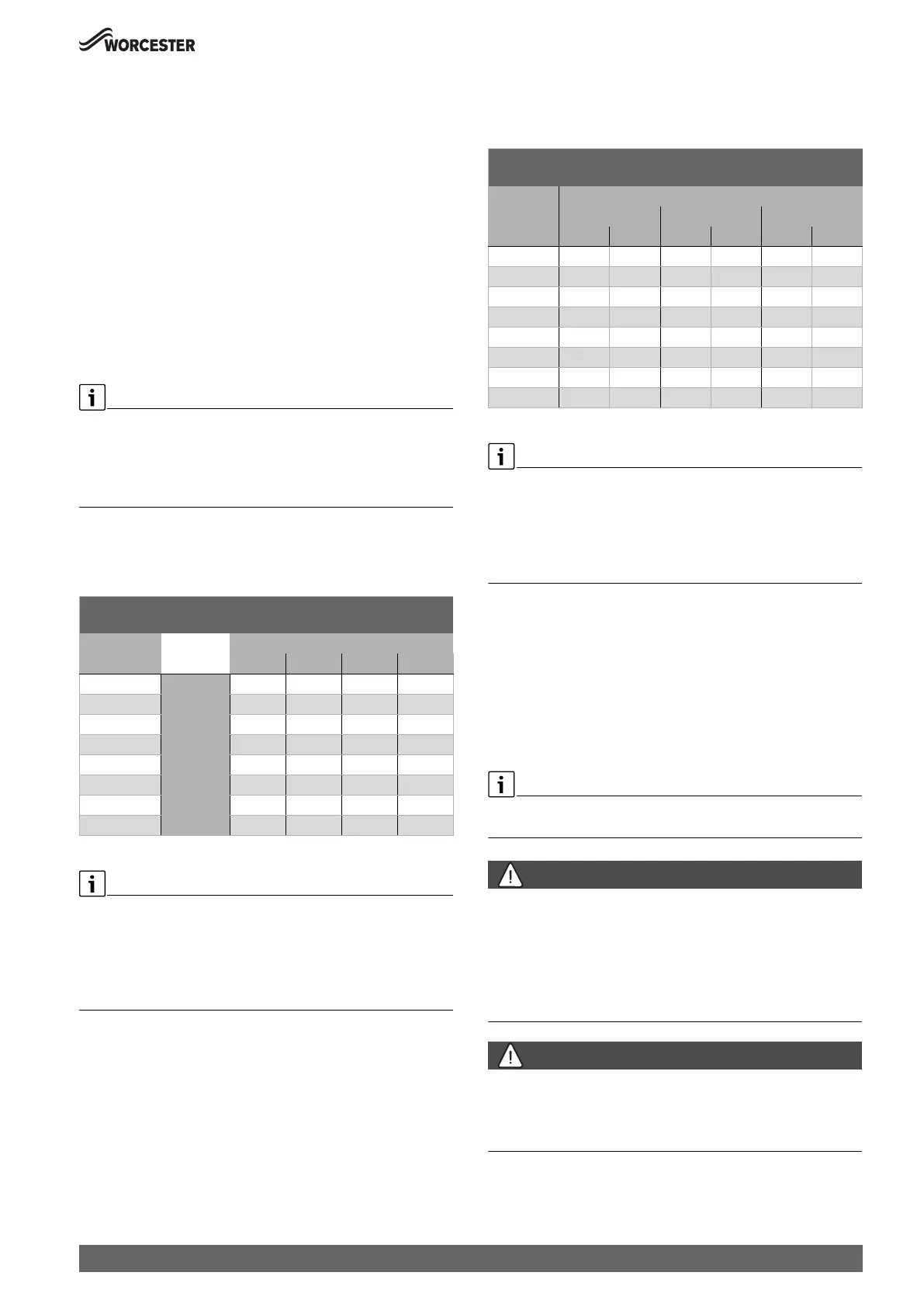

Liquid Petroleum Gas (LPG):

Discharge rates for copper tube with 2.5mbar differential pressure

between the ends for LPG.

Table 6 Liquid Petroleum Gas (LPG)

Liquid Petroleum Gas (LPG):

▶ When using this table to estimate the Gas flow rate in pipe work of a

known length, the effective length will be increased by 0.6m for each

90° elbow or tee and by 0.3m for each 90° bend or straight coupler.

This method is only a estimate - for more complex design please refer

to BS6891 2015 and training given in ACS.

4.3 Appliance location and clearances

4.3.1 Appliance location

• Follow local regulations for the location within the property that the

appliance is to be installed.

• This appliance is only suitable for installing internally within a

property at a suitable location onto a flat, fixed rigid surface capable

of supporting the appliance weight.

• The appliance is not suitable for external installation.

No surface protection is required againat heat transfer from the

appliance

DANGER:

Danger to life due to explosion!

An increased and permanent ammonia concentration can lead to stress

corrosion cracking on brass parts (e.g. gas taps, union nuts). As a result,

there is a risk of explosion due to gas leakage.

▶ Do not use gas appliances in rooms with an increased and permanent

ammonia concentration (e.g. livestock stables or storage rooms for

fertilisers).

DANGER:

Danger from explosive and flammable materials:

Storage of explosive and flammable materials.

▶ Do not store flammable materials (paper, curtains, clothing, primer,

paint, …) in proximity to the appliance.

Discharge rates for Natural Gas (m

3

/hr)

with straight horizontal copper tube

Pipe Pipe Size (mm)

Length (m) 15 22 28 35

3

2.9 8.7 18 32

6 1.9 5.8 12 22

9

1.5 4.6 9.4 17

12 Discharge 1.3 3.9 8 15

15

m

3

/hr 1.1 3.4 7 13

20 0.95 2.9 5.9 11

25

0.92 2.5 5.2 9.5

30 0.88 2.3 4.7 8.5

Discharge rates for LPG (m

3

/hr & kW)

with straight horizontal copper tube

Tubing Outside diameter

Length (m) 15mm 22mm 28mm

kW m

3

/hr kW m

3

/hr kW m

3

/hr

3 38.4 1.49 207 8.01 412 15.92

6 26.1 1.01 135 5.21 230 8.86

9 20.5 0.79 108 4.19 215 8.33

12 17.9 0.70 94 3.62 187 7.25

15 15.5 0.60 82 3.20 168 6.51

18 13.5 0.53 74 2.86 145 5.61

21 12.9 0.50 67 2.58 135 5.24

24 12.0 0.47 61 2.58 126 4.87

Loading...

Loading...