By using an analogue sensor, two adjustable alarm limits can be used, one for warning (“B”-

alarm) and one for pump stop (“A”-alarm).

3.6.4 Pump memory

The pump memory is located inside the junction box of the pump. The memory is loaded

with data from the factory, which is then uploaded to the MAS system at first start-up.

The data that is uploaded contains the following features:

•

Data plate information

• Sensor types and alarm settings recommended by the manufacturer

• Operational data and data to support service:

– Histograms of temperatures, vibrations, and cycle length

– Start and stop registration

– Service log with a maximum of 200 lines of text

– Conditions to prompt for service based on for example, running time, number of starts

and stops or specific dates

For more information, see the MAS 711 Installation and User Manual.

3.7 Monitoring with MiniCAS II

This table shows the parameters which can be tracked with the MiniCAS II monitoring

system.

Parameter Sensor Standard or optional

Stator winding temperature One of the following choices:

• Standard: 3 thermal switches

• Optional: 3 PTC thermistors

Standard

Leakage in the inspection

chamber

Float switch leakage sensor (FLS) Standard

Leakage in the junction box Float switch leakage sensor (FLS) Optional

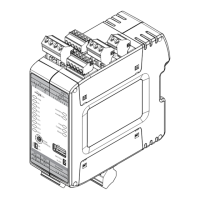

3.7.1 MiniCAS II

One MiniCAS II is required for each pump.

1. Combined power and signal cable

2. MiniCAS II

MiniCAS II features include the following:

• Two pump sensors

• Signal leads are incorporated in the SUBCAB

®

power cable.

• LED alarm indication

3.8 Column adapters

There are two accessories which can be used to install these pumps in slightly larger

columns:

• Diffuser adapter

• Flange adapter

3 Product Description

20 P7030, P7035, P7040 Installation, Operation, and Maintenance Manual

Loading...

Loading...