Do you have a question about the Xylem FLYGT P7030 Series and is the answer not in the manual?

Purpose and importance of reading the manual.

Understanding safety messages, hazard levels, and symbols.

Guidelines for safe operation and Ex-approved installations.

Risks associated with biological hazards and chemical contact.

Emissions, waste disposal, and end-of-life procedures.

Importance of original parts and warranty information.

Procedures for inspecting units and transport safety.

Temperature limits and handling procedures for the unit.

Recommendations for proper storage locations and methods.

List of pump models and their standard or EX variants.

Specifications and usage guidelines for the pump.

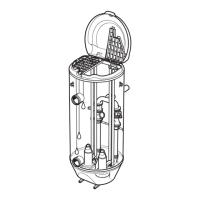

Detailed breakdown of pump components with visual aids.

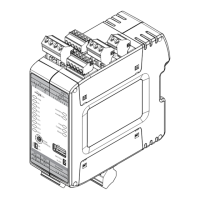

Introduction to MiniCAS II, MAS 711, and MAS 801 systems.

Comprehensive features, components, and functions of the MAS 801 system.

Monitoring bearing temperatures with Pt100 sensors.

Methods for monitoring stator winding temperatures.

Monitoring electrical parameters with MAS 801.

Usage, components, and sensor types for the MAS 711 system.

Methods for monitoring stator winding temperatures.

Data logging and retrieval capabilities.

Parameters tracked by the MiniCAS II system.

Information on diffuser and flange adapters.

Explanation of the specifications shown on the unit's data plate.

Exemption from efficiency requirements for submersible motors.

Details on ATEX, IECEx, FM, and CSA certifications.

Guide to interpreting product code characters.

General safety, electrical, explosion, inhalation, and fall hazards.

General guidelines and conditions for pump cables.

Specifications for cable support and protection systems.

Procedure and equipment for installing the diffuser adapter.

Steps and consultations required for installing the pump.

Safety precautions, electrical hookups, and grounding procedures.

Components used for sealing the cable entry points.

Step-by-step guide for preparing pump cables.

Wiring instructions for standard pumps with MAS 801.

Wiring instructions for Ex-proof pumps with MAS 801.

Wiring procedures for MiniCAS and MAS 711 systems.

Understanding and verifying power cable phase connections.

Bending radius, weight, and diameter for SUBCAB cables.

Interpreting symbols and motor connection diagrams.

Control lead colors for MiniCAS sensor wiring.

Wiring FLS and thermal detectors for MiniCAS.

Procedure to verify correct propeller rotation direction.

Safety checks before putting the unit into operation.

Method for calculating zinc anode lifespan.

Step-by-step guide for safely starting the pump.

Safety measures before and during maintenance work.

Specifications for tightening screws and nuts.

Procedure for verifying temperature sensor functionality.

Procedure for testing float switch (FLS) sensors.

Steps for draining and refilling pump oil.

Procedure for replacing the PEM in MAS 801 systems.

Steps before working on the pump's hydraulic components.

Tools, steps, and clearance measurement for propeller replacement.

Detailed steps for removing the propeller.

Detailed steps for installing the propeller.

Procedure for replacing the pump's bellmouth.

Procedure for replacing the pump's zinc anodes.

General service guidelines and detailed inspection checks.

Actions required for a major pump overhaul.

Troubleshooting steps based on alarm sources.

Guidelines for diagnosing electrical faults.

Causes and remedies when the pump doesn't start.

Issues with pump stopping when using level sensors.

Troubleshooting frequent pump cycling.

Causes and solutions when motor protection activates.

Diagnosing low flow or no water output.

Maximum operating parameters for the pump.

Temperature-to-resistance data for Pt100 sensors.

| Type | Submersible Pump |

|---|---|

| Maximum Submergence | 20 m |

| Motor Speed | 2900 rpm |

| pH of the Pumped Liquid | 6-14 |

| Pump Material | Cast Iron |

| Seal Type | Mechanical Seal |

| Protection Class | IP68 |

| Liquid Temperature | 0°C to 40°C |

| Voltage | 400V |

| Frequency | 50 Hz |

| Max Head (m) | 60 m |

| Discharge Size | DN 80 - DN 150 (3 - 6 in) |