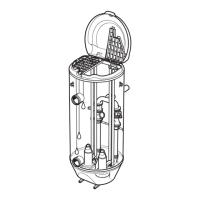

1. Discharge column

2.

Antirotation gusset (stop vanes)

3. Pump seat

4. Anti-rotation device on hydraulic end

Figure 9: Without adapter, with flange adapter, and with diffuser adapter

When the pump is installed in a discharge tube, the following must be considered:

• A suitable cable support and protection system must be used.

Before installation, check the following:

• The rubber seal ring underneath the pump is in place.

• There is no damage to, or debris on, the pump seat.

• There is no large construction debris under the pump tube. If debris is present, then there

is a risk that it gets sucked into the pump and cause propeller damage.

1. Make sure that the pump control is set to turn off the pump at or above the minimum

operating water level for this pump installation.

2. If a diffuser adapter will be used at the site, then make sure that the adapter is in place.

See

Install the diffuser adapter

on page 30.

3. Check that the cables and cable entries have not been damaged during transport.

4. Secure the cables so that they can be fed into the column in a controlled manner.

When the pump is lowered into the column, the cables must be fed into the column at the

same speed as the pump is lowered.

4 Installation

34 P7030, P7035, P7040 Installation, Operation, and Maintenance Manual

Loading...

Loading...