8-41

8

ROBOT LANGUAGE

8-5 Sample Programs

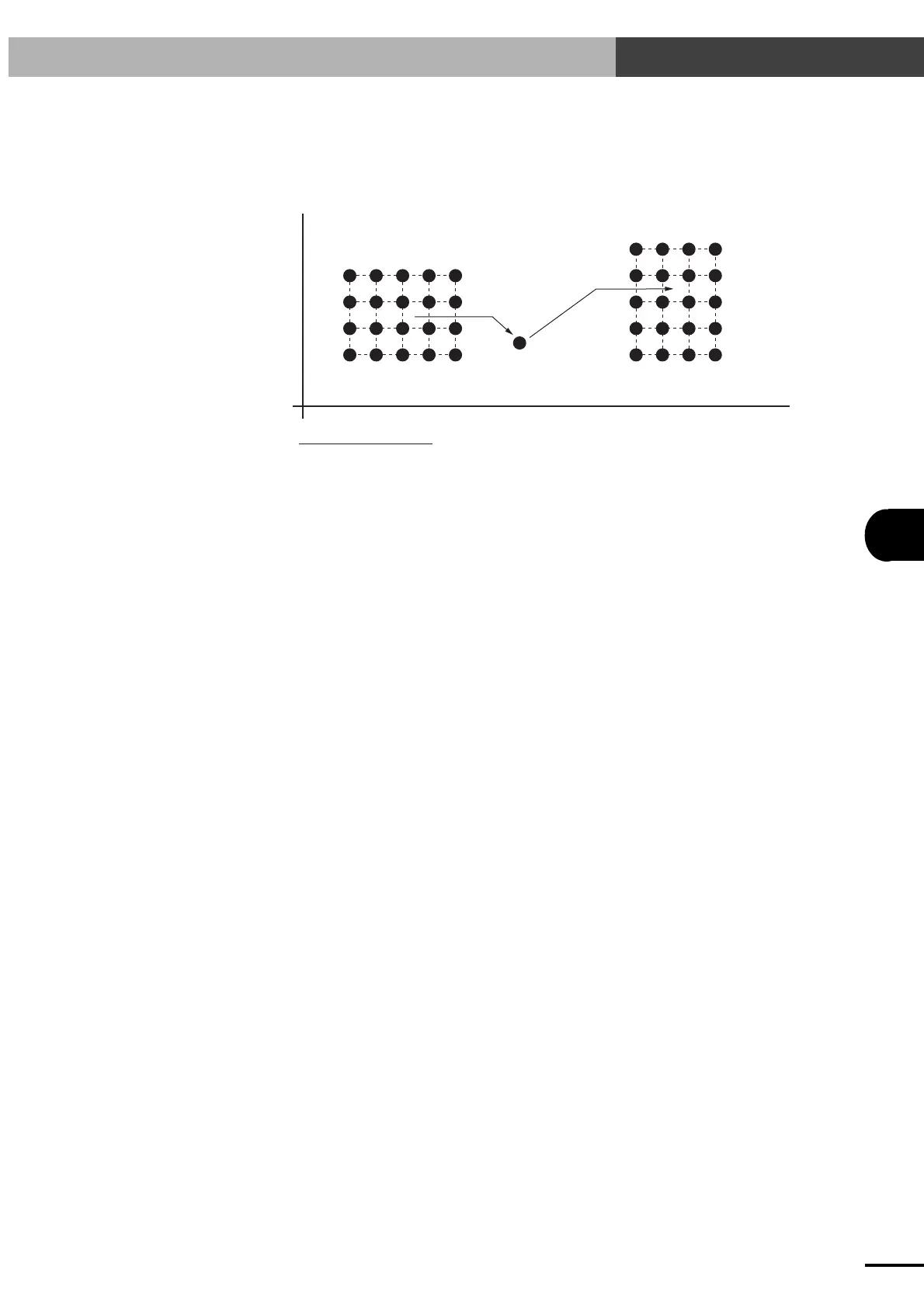

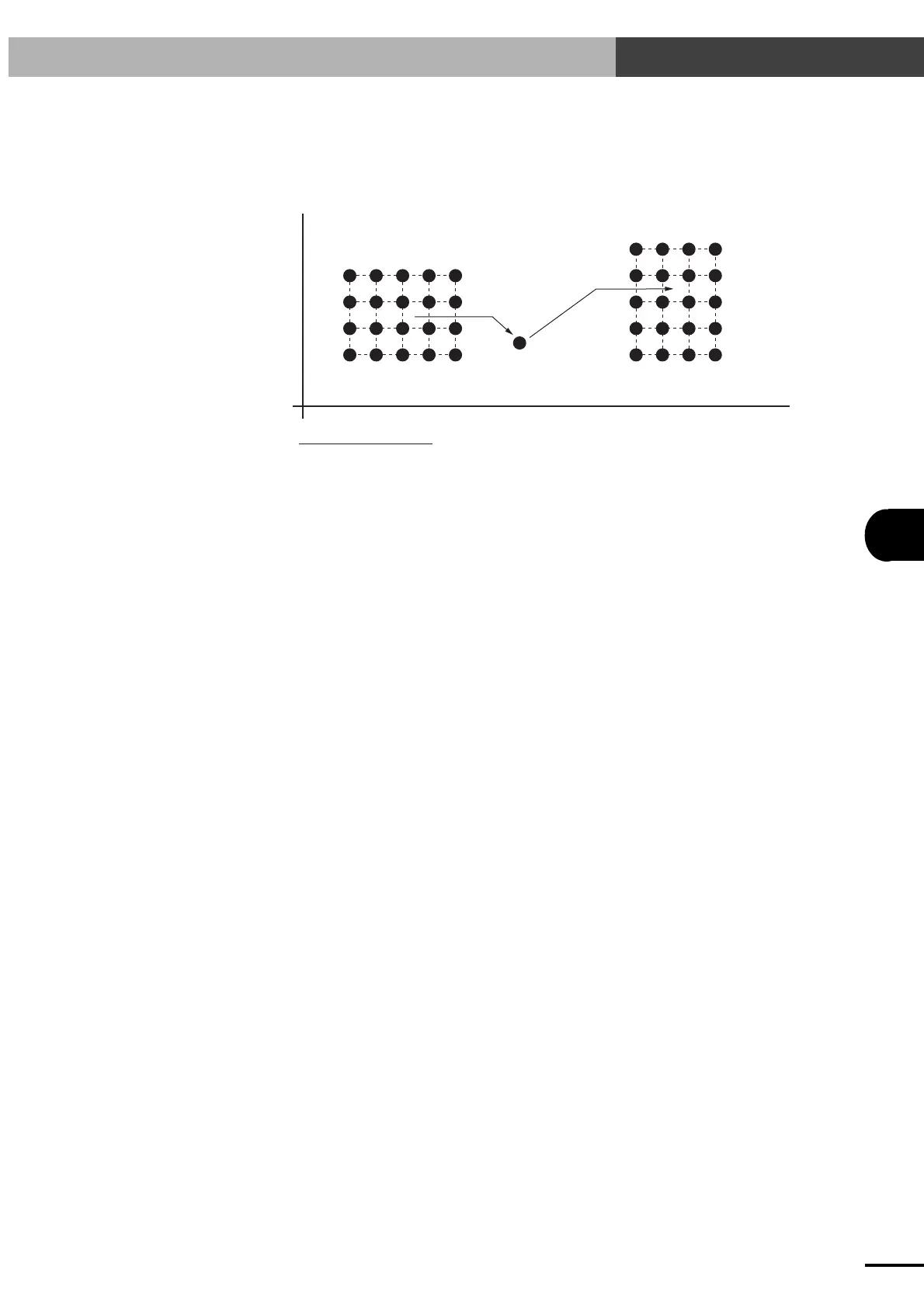

8-5-8 Palletizing for pallet versus pallet

With this sample program, the robot picks up a workpiece from a pallet, places it in the processing

position P0, and then picks up and places the processed workpiece on a transport pallet.

Pick-and-place sequence

point a → P0 → point A → ··· → point b → P0 → point B → ··· →

point c → P0 → point C → ··· → point d → P0 → point D

Point c (=P253)

Point d (=P254)

Workpiece

processing position

P0

Point a (=P251)

Point b (=P252)

Point B (=P248)

Point D (=P250)

Point A (=P247)

Point C (=P249)

Y

X

■ Teaching each point of P0 and P247 to P254 should be completed beforehand in PNT

(point) mode. (Supply pallet is defined as pallet number 0, and transport pallet as pallet

number 1 in this example.)

Program Comment

[NO0]

001: MAT 4, 5, 0 ; 4×5 matrix definition (for supply pallet)

002: MAT 4, 5, 1 ; 4×5 matrix definition (for transfer pallet)

003: C 1 ; Sets counter variable to 1

004: L 0 ; Label definition

005: MSEL 0 ; Matrix selection for feed pallet

006: MOVM C, 100 ; Moves to supply pallet

007: CALL 1, 1 ; PICK routine call

008: MOVA 0, 100 ; Moves to processing position

009: CALL 2, 1 ; PLACE routine call

010: CALL 3, 1 ; Workpiece processing routine call

011: CALL 1, 1 ; PICK routine call

012: MSEL 1 ; Matrix selection for transfer pallet

013: MOVM C, 100 ; Moves to transfer pallet

014: CALL 2, 1 ; PLACE routine call

015: JMPC 1, 20 ; Jumps to L1 if counter variable is 20

016: C+ ; Counter variable increment

017: JMP 0, 0 ; Jumps to L0

018: L 1 ; Label definition

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Loading...

Loading...