8-44

8

ROBOT LANGUAGE

8-5 Sample Programs

8-5-11

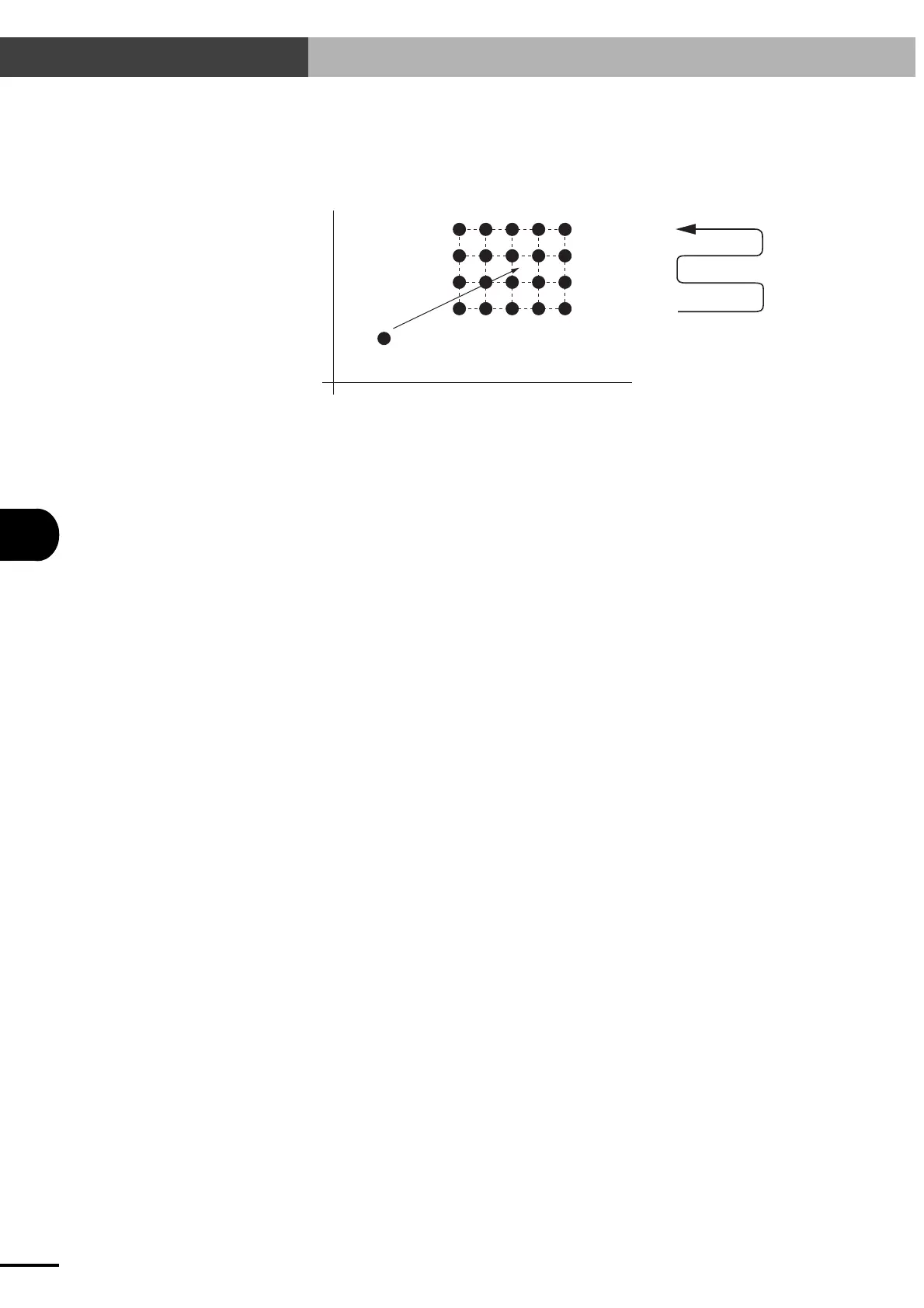

Changing the placement sequence for palletizing

With this sample program, the robot picks up a workpiece supplied at P0 and place it sequentially on

a 4×5 pallet with the placement sequence shown below.

Point B (=P252)

Point C (=P253)

Point D (=P254)

Place points

Pick point

Point A (=P251)

P0

X

Y

Placement sequence

■ Teaching each point of P0 and P251 to P254 should be completed beforehand in PNT

(point) mode. (Matrix is defined as pallet number 0 in this example.)

Program Comment

[NO0] <<Main routine>>

001: MAT 4, 5, 0 ; Defines 4×5 matrix as pallet number 0

002: C 1 ; Sets counter variable to 1

003: CALL 1, 5 ; Calls subroutine NO1 five times

004: C 10 ; Sets counter variable to 10

005: CALL 2, 5 ; Calls subroutine NO2 five times

006: C 11 ; Sets counter variable to 11

007: CALL 1, 5 ; Calls subroutine NO1 five times

008: C 20 ; Sets counter variable to 20

009: CALL 2, 5 ; Calls subroutine NO2 five times

[NO1] <<Execution while counting up>>

001: MOVA 0, 100 ; Moves to pick point

002: CALL 3, 1 ; PICK routine call

003: MSEL 0 ; Specifies movement matrix

004: MOVM C, 100 ; Moves to place point (on pallet)

005: CALL 4, 1 ; PLACE routine call

006: C+ ; Counter variable increment

[NO2] << Execution while counting down>>

001: MOVA 0, 100 ; Moves to feed source point

002: CALL 3, 1 ; PICK routine call

003: MSEL 0 ; Specifies movement matrix

004: MOVM C, 100 ; Moves to place point (on pallet)

005: CALL 4, 1 ; PLACE routine call

006: C- ; Counter variable decrement

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Loading...

Loading...