51

CHAPTER2 PROFIBUS Unit

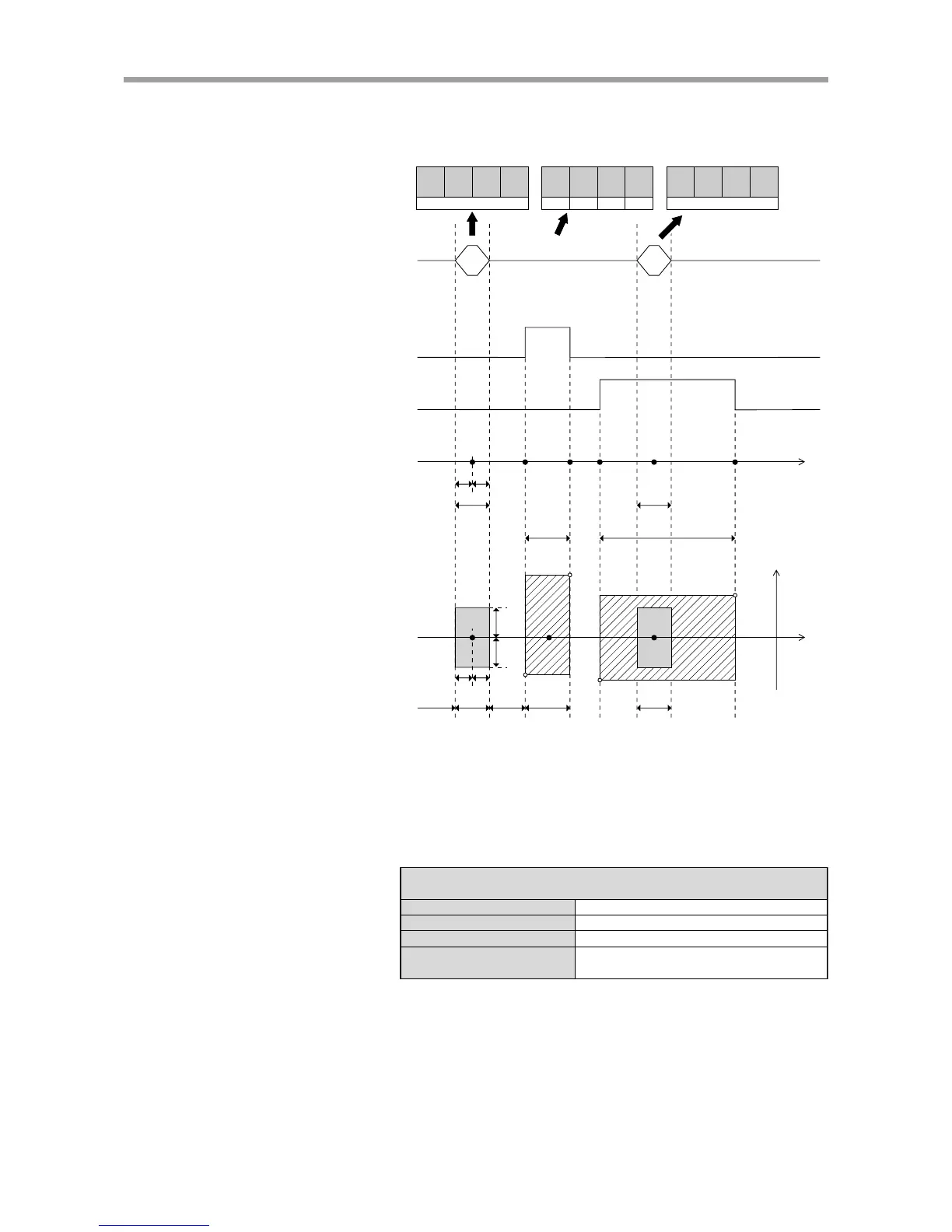

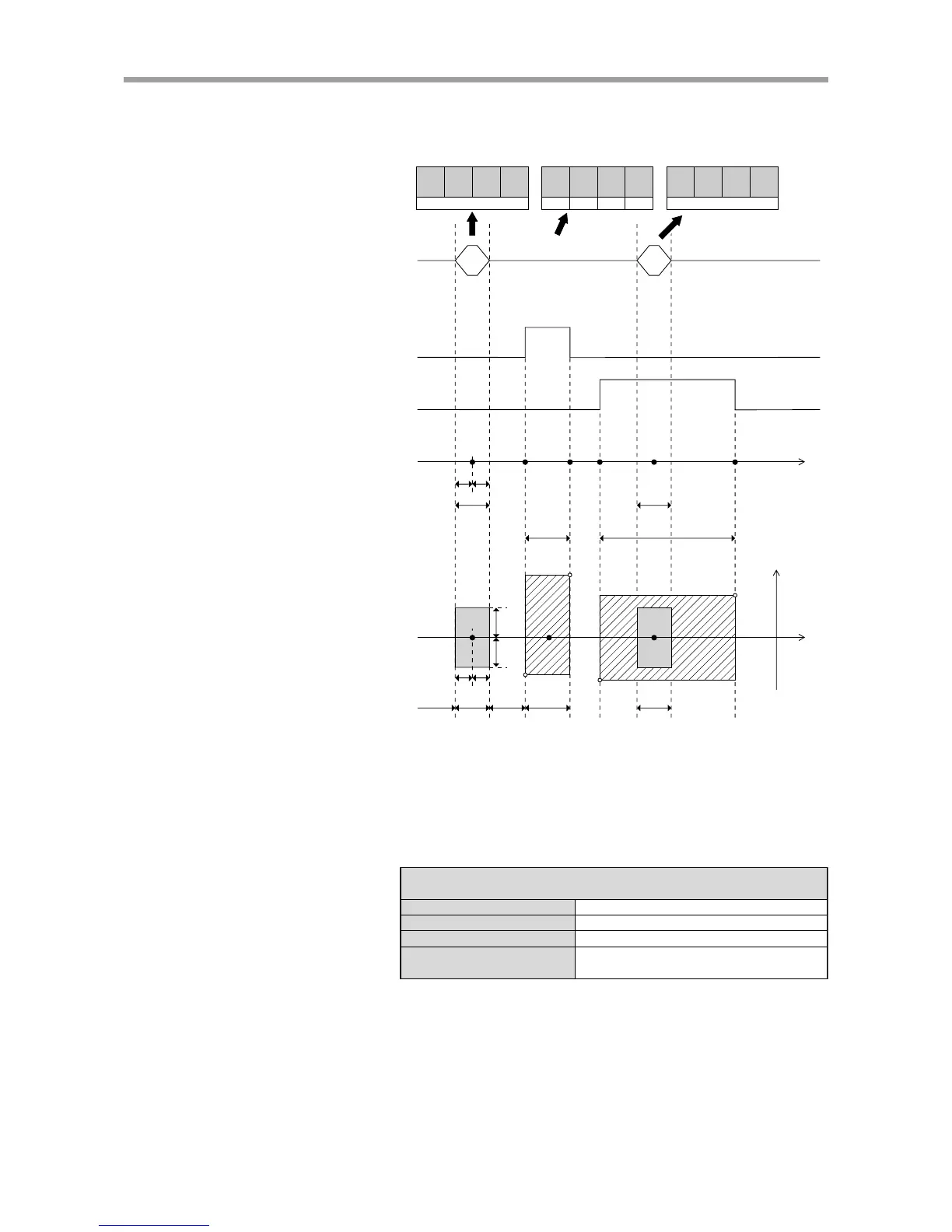

(3) Outputting the corresponding point number by the point zone output

function

Zone outputs (ZONE 0, ZONE 1) are also explained here.

a: X-axis position judgment parameter range

b: Y-axis position judgment parameter range

(In this case, this is the OUT valid position range.)

PO

203

(2

3

)

PO

202

(2

2

)

PO

201

(2

1

)

PO

200

(2

0

)

PO

203

(2

3

)

PO

202

(2

2

)

PO

201

(2

1

)

PO

200

(2

0

)

PO200 to 203

(Target position's point number

outputs 200 to 203)

ZONE0 (Zone output 0)

ZONE1 (Zone output 1)

Current robot position

*Positive logic

*Positive logic

aa

X+

Pm P902

Point output

(point n)

m-No. is output as binary value

OFF OFF OFF OFF

n-No. is output as binary value

Current robot position

aa

Pm

* The number of target point number outputs that can be used depends on I/O assignment type.

qwe

r

t

X+

b

b

P900

Zone output range

* For single-axis type

* For dual-axis type

Precondition: 1) The following steps are explained assuming that the I/O assign-

ment selection parameter (single-axis controllers: PRM59, dual-

axis controllers: PRM26) is set to 221.

I/O assignment type

Permissible number of movement points

Point output selection

Point zone judgment method

(position judgment parameter)

When I/O assignment selection parameter = 221

(single-axis controllers: PRM59, dual-axis controllers: PRM26)

Type 2 (Point No. output type)

16 points

Point zone output

OUT valid position

2) The Zone 0 output and Zone 1 output are enabled and set to posi-

tive logic output by the Zone output selection parameter (single-

axis controllers: PRM53, dual-axis controllers: PRM24).

(1) Target position's point number outputs PO200 to PO203 are off since the cur-

rent robot position is not within the point zone output range. ZONE 0 and

ZONE 1 output signals are also off since the robot does not yet enter the zone

output range.

Loading...

Loading...