nment type.

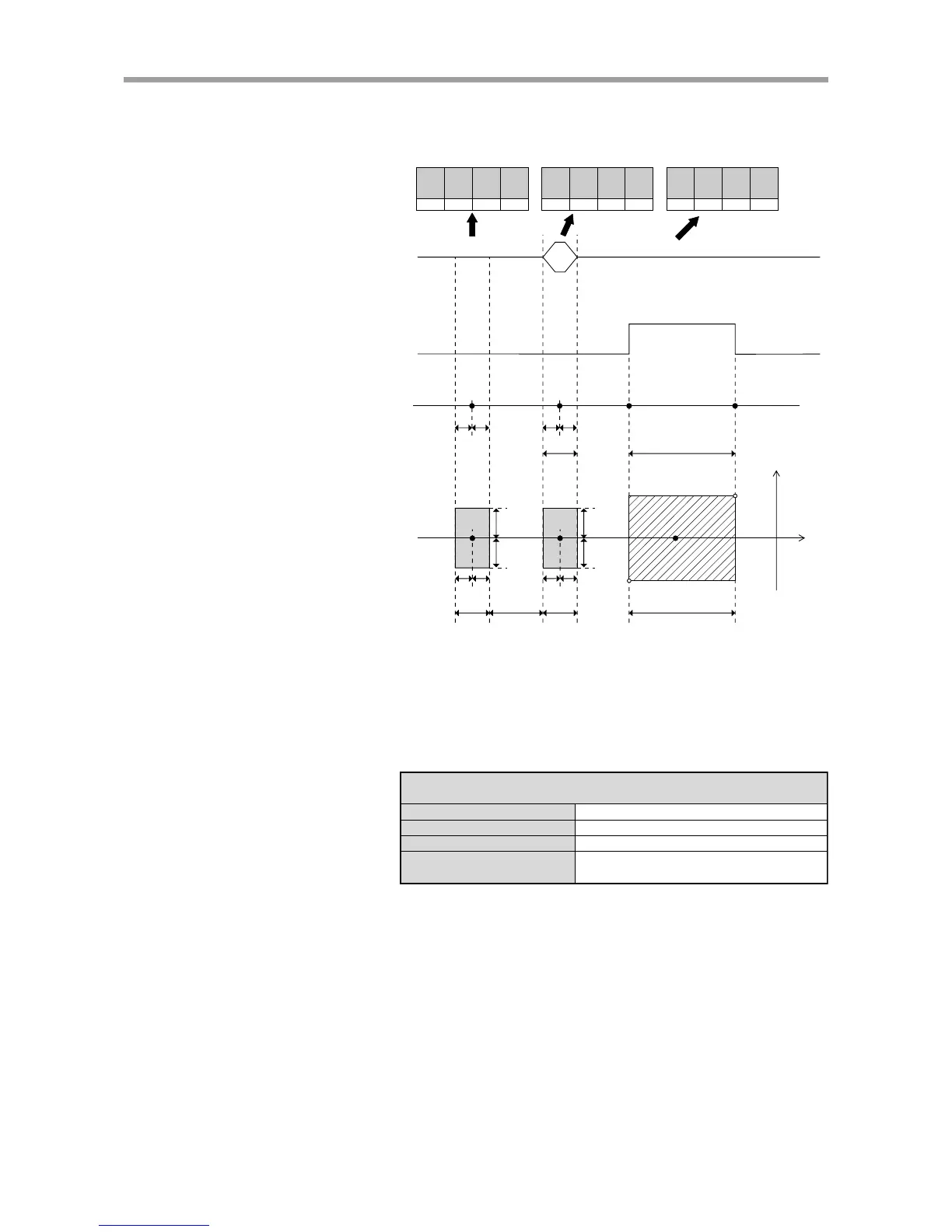

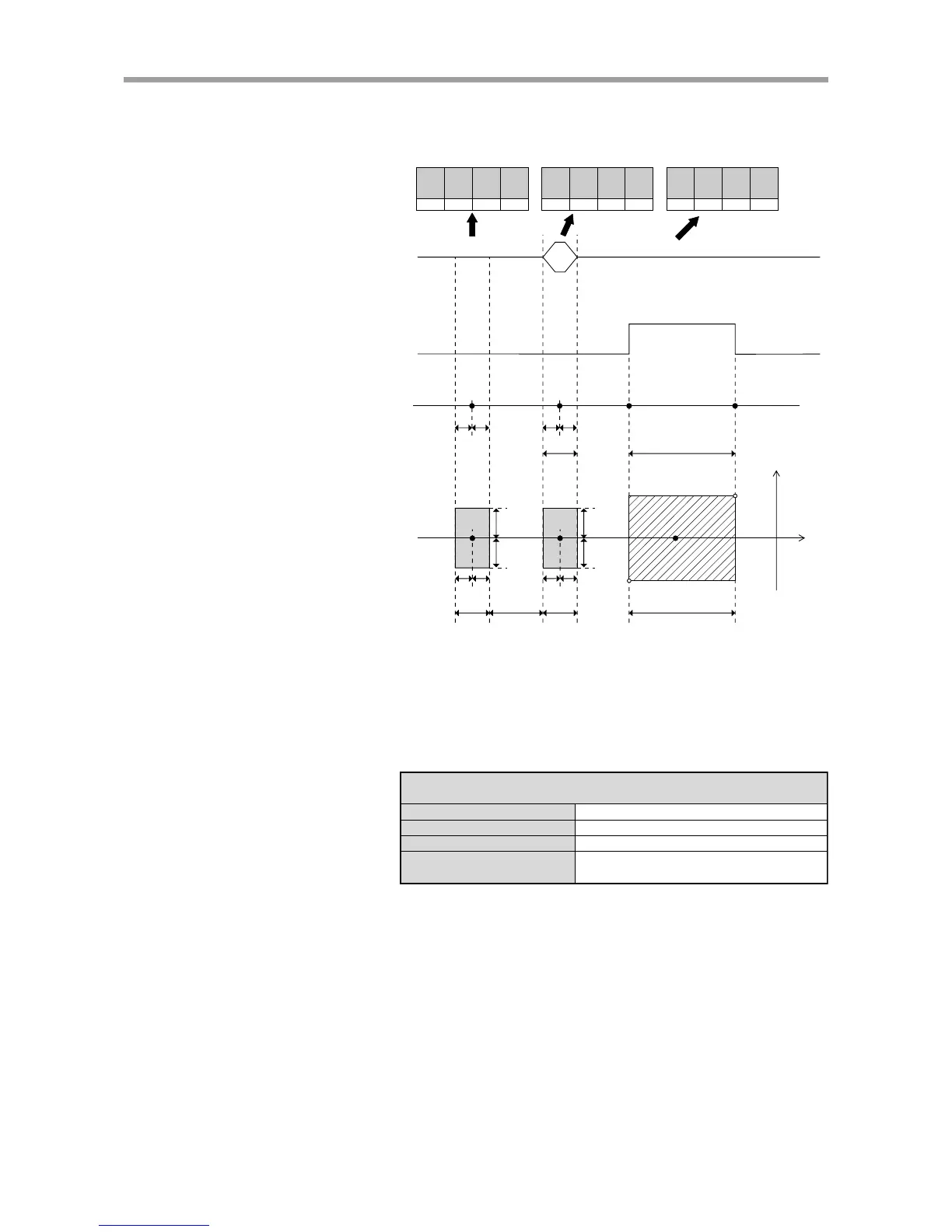

q w r

X+

b

b

Y+

a: X-axis position judgment parameter range

b: Y-axis position judgment parameter range

(In this case, this is the OUT valid position range.)

OFF OFFON ONOFF OFF OFF OFFOFFOFF OFF OFF

aa

P6

e

Point zone output range

* For single-axis type

* For dual-axis type

Precondition: 1) The following steps are explained assuming that the I/O assign-

ment selection parameter (single-axis controllers: PRM59, dual-

axis controllers: PRM26) is set to 321.

I/O assignment type

Permissible number of movement points

Point output selection

Point zone judgment method

(position judgment parameter)

When I/O assignment selection parameter = 321

(single-axis controllers: PRM59, dual-axis controllers: PRM26)

Type 2 (Point No. output type)

16 points

Movement point zone output

OUT valid position

2) The Zone 0 output is enabled and set to positive logic output by the

Zone output selection parameter (single-axis controllers: PRM53,

dual-axis controllers: PRM24).

3) Set the movement point as P6.

(1) Although the robot is within the P1 ± OUT valid position range (point zone

output range), all the PO200 to PO203 target position point number outputs are

off because P1 is not the movement point. Moreover, the ZONE 0 output is

also off because the robot is not within the specified zone output range.

(2) All the PO200 to PO203 target position point number outputs are off because

the robot is not within the point zone output range. Moreover, the ZONE 0

output is also off because the robot is not within the specified zone output

range.

Loading...

Loading...