F.

Cylinder

1.

Visually check the cylinder walls for

scratches.

If vertical scratches

are

evi-

dent, the

cylinder wall should be rebored

or the

cylinder should

be

replaced.

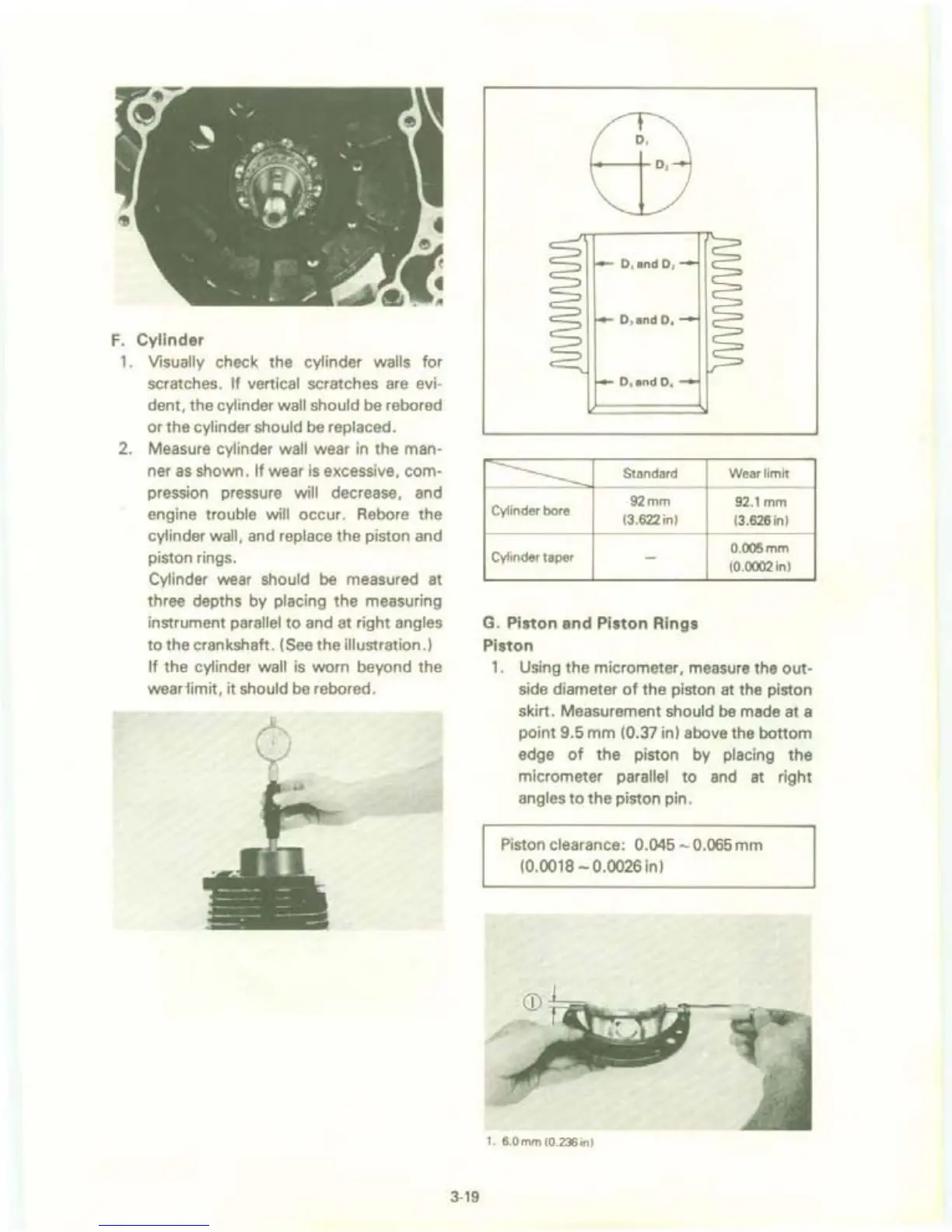

2.

Measure cylinder wall wear

in

the man-

ner

as

shown. If wear is excessive, com-

pression pressure will decrease, and

engine

trouble will occur. Rebore the

cylinder wall, and replace the piston and

piston rings.

Cylinder wear should

be

measured at

three depths by

placing the measuring

instrument

parallel

to

and at right angles

to the crankshaft. (See the illustration.)

If the cylinder wall is worn beyond the

wear'limit, it should

be

rebored.

3-19

0,

and

0,

0 3

and

O.

O,

and

O.

---------

Standard

Cylinder

bore

92mm

(3.622 in)

Cylinder taper

-

G. Piston and Piston Rings

Piston

Wear limit

92.1

mm

(3.626 in)

0.OO5mm

(0.0002

in)

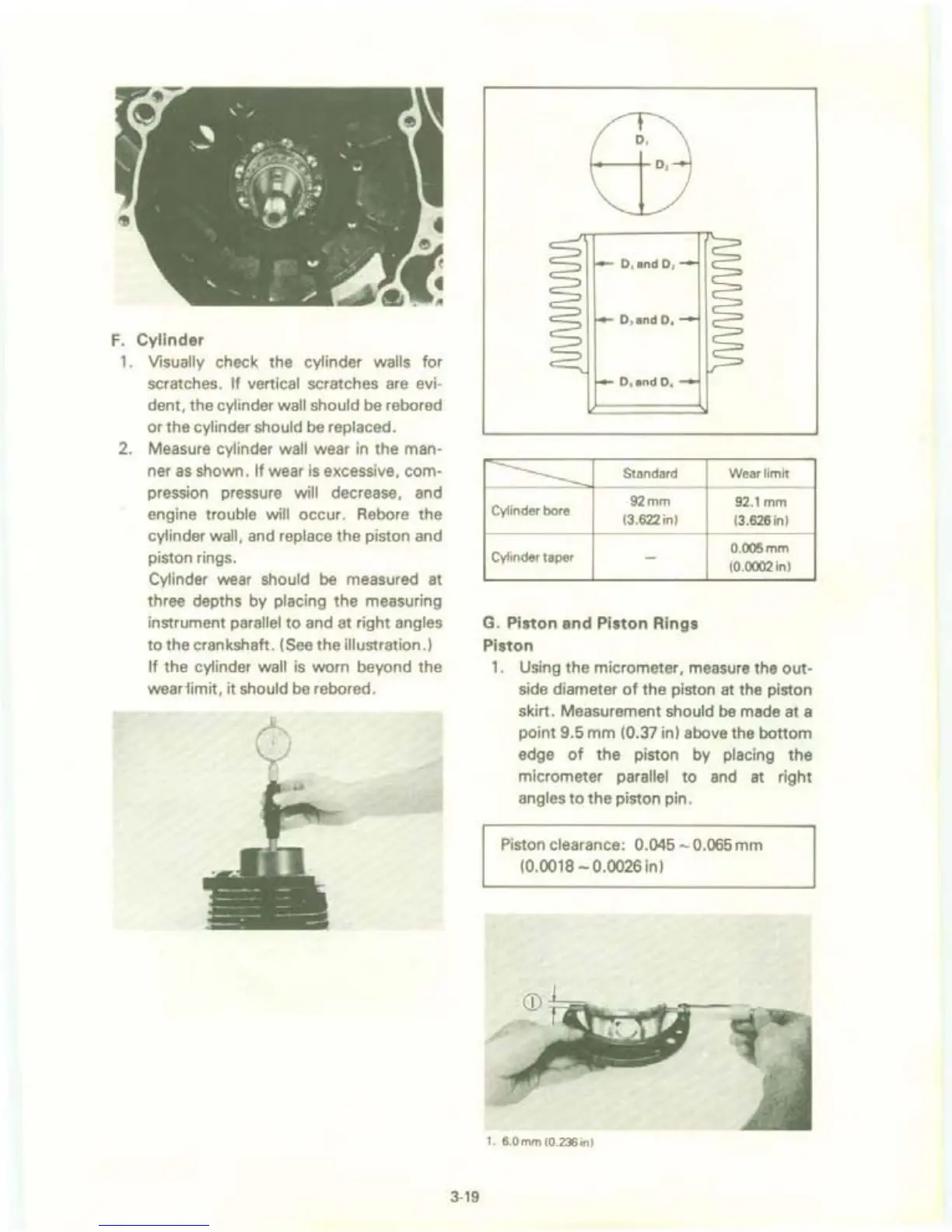

1.

Using the micrometer, measure the out-

side diameter

of

the piston at the piston

skirt. Measurement

should

be

made at a

point 9.5

mm

(0.37 in) above the bottom

edge

of

the piston by placing the

micrometer

parallel to

and

at right

angles

to

the piston pin.

Piston clearance:

0.045 - 0.065 mm

(0.0018 - 0.0026 in)

1. 6.

0mm

(0,236 in)

Loading...

Loading...