TURBOCHARGER

Tests and Adjustments

12/05

BY Service Manual

9-5

© 2009 Yanmar Marine International

TESTS AND ADJUSTMENTS

Measure Charge Pressure

The turbocharger charge pressure can be

measured using a console digital display.

Low charge pressure can be due to compressor

wheel or turbine wheel damage, control rod wear or

dirt in the compressor housing.

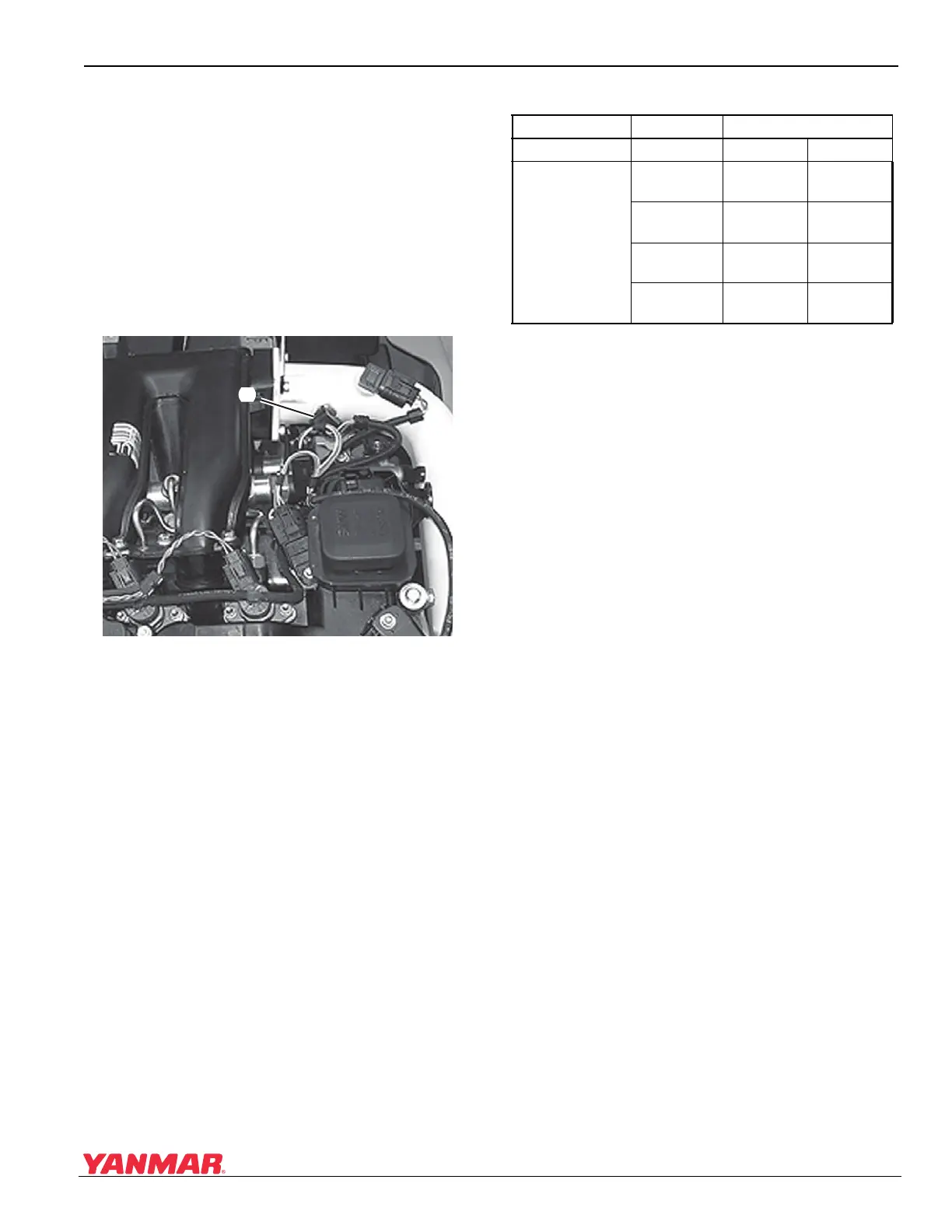

1. Remove charge air temperature sensor

(Figure 9-1, (1)) from charge air intake pipe.

Figure 9-1

Figure 9-1

2. Install an M12 x 1.5 adapter and connect a

mechanical gauge to the charge air

temperature sensor port.

3. Operate the engine under normal load

conditions at wide open throttle (4000 rpm) and

take a reading after at least 30 seconds of

constant operation.

Results:

If the reading is not within specification, adjust the

control rod (4BY2) or replace the turbocharger.

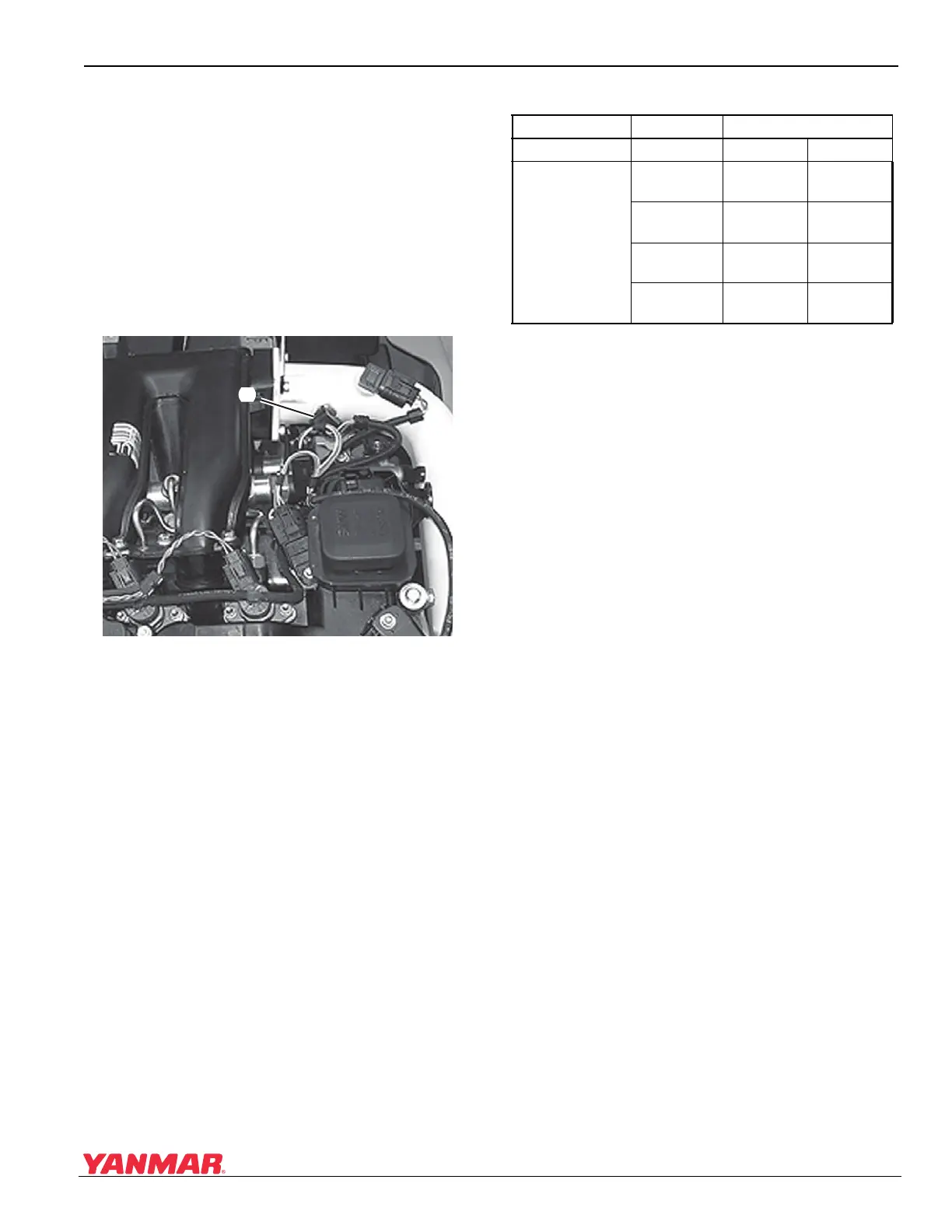

Specifications

(

1

)

0003769B

Limit

Inspection Item Engine Minimum Maximum

Turbocharger

Boost Pressure

4BY2-150

1600 mbar

(23.2 psi)

1750 mbar

(25.4 psi)

4BY2-180

1650 mbar

(23.9 psi)

1800 mbar

(26.1 psi)

6BY2-220

1950 mbar

(28.3 psi)

2150 mbar

(31.2 psi)

6BY2-260

2000 mbar

(29.0 psi)

2200 mbar

(31.9 psi)

Loading...

Loading...