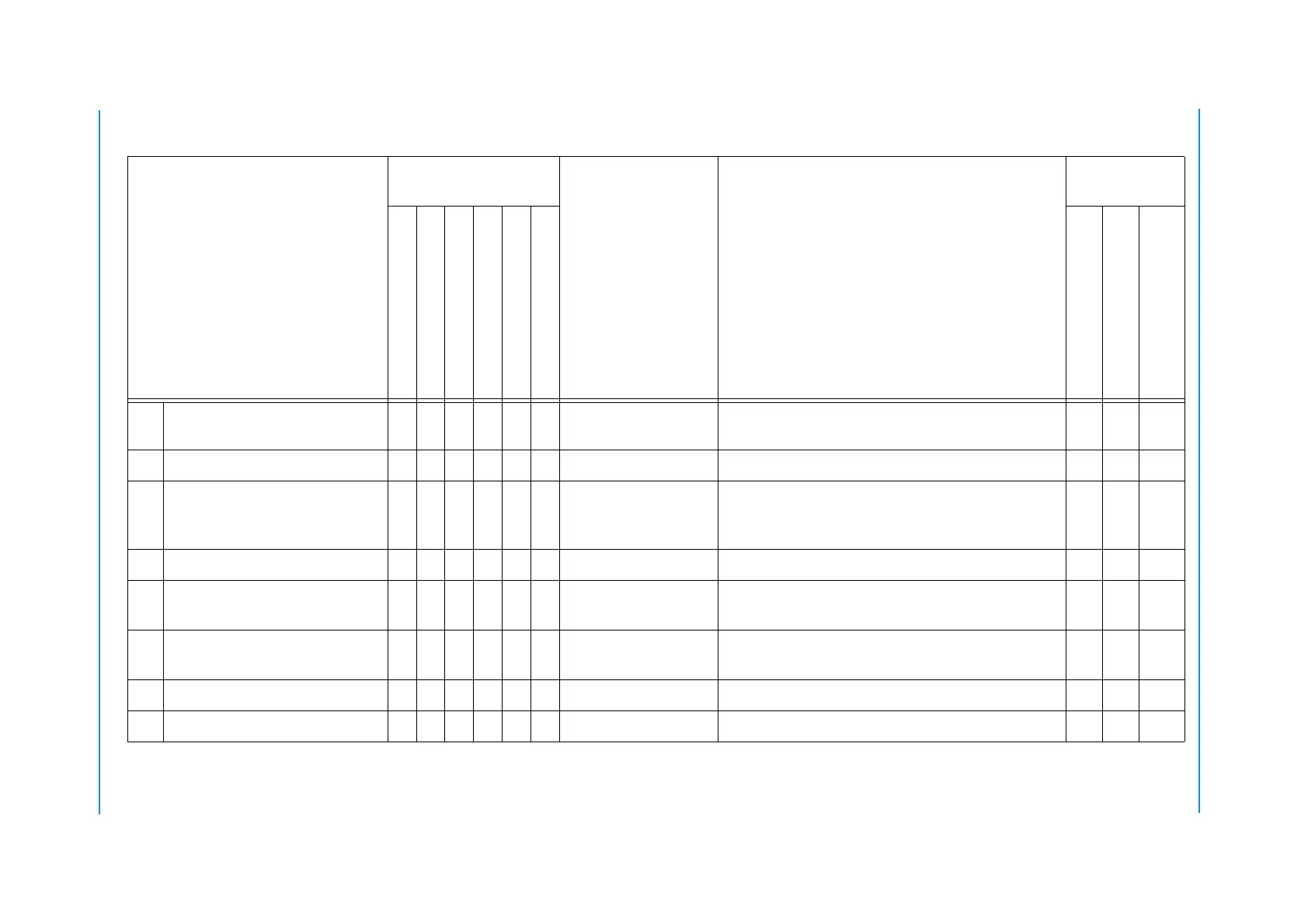

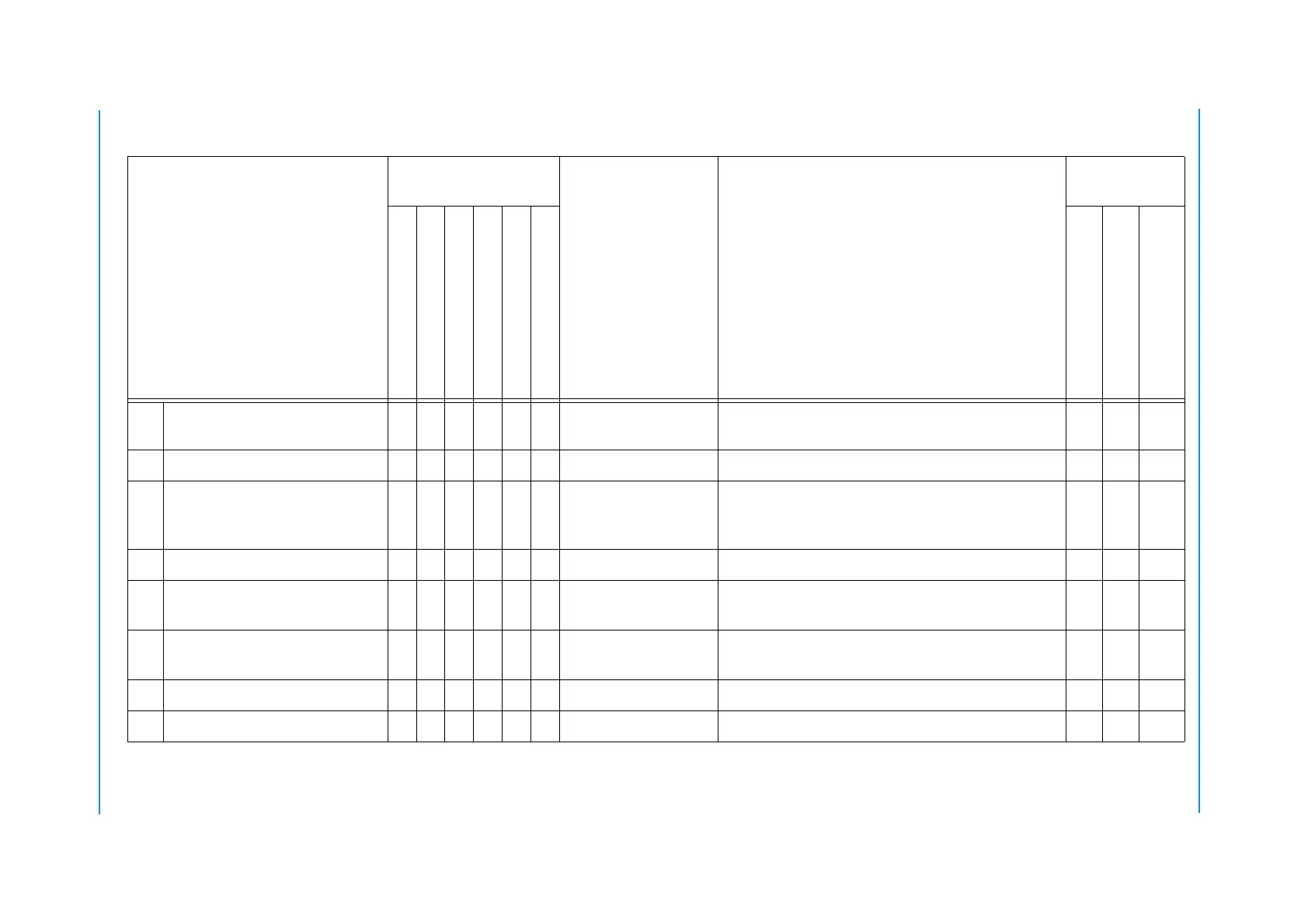

Maintenance and inspection

9

- 47

Inspection intervals

Item number

1

Schedule Checking method Operation Inspection

Charge:

Daily

Every 1000 hours

Every 6000 hours

Every 12000 hours

Every 24000 hours

Every 36000 hours

trained staff

YASKAWA trained staff

YASKAWA staff

1 Alignment marks Visual inspection Check alignment mark accordance and damage

at the home position.

2 External cable Visual inspection Check cable for damage.

3 Working area and robot Visual inspection Dirty working area has to be cleaned. Please

control the robot for damage and external

cracks.

4 Motor for S-, L-, U-axes Visual inspection Check for grease leakage.

5 Baseplate mounting bolts Using correspond-

ing tool

Tighten loose screws (replace if necessary).

6 Cover mounting screws Using correspond-

ing tool

Tighten loose screws (replace if necessary).

7 Power input module Manual Check for loose connectors

8 Toothed belt for B- and T-axes Manual Check for tension and wear

Loading...

Loading...