6.2 Motion Command Details

6.2.2 Latch Target Positioning (EX_POSING) (External Positioning)

6-12

5.

Set OW08 to 0 to execute the NOP motion command to complete the external positioning opera-

tion.

( 2 ) Holding

Axis travel can be stopped during command execution and then the remaining travel can be restarted. A command is

held by setting the Holds a Command bit (OW09, bit 0) to 1.

• Set the Holds a Command bit (OW09, bit 0) to 1. The axis will decelerate to a stop.

• When the axis has stopped, the Command Hold Completed bit (IW09, bit 1) will turn ON.

• Reset the Holds a Command bit (OW09, bit 0) to 0.

The command hold status will be cleared and the remaining portion of the positioning will be restarted.

( 3 ) Aborting

Axis travel can be stopped during command execution and the remaining travel canceled by aborting execution of a

command. A command is aborted by setting the Interrupt a Command bit (OW09, bit 1) to 1.

• Set the Interrupt a Command bit (OW09, bit 1) to 1. The axis will decelerate to a stop.

• When the axis has stopped, the remain travel will be canceled and the Positioning Completed bit (IW0C,

bit 1) will turn ON.

This type of operation will also be performed if the motion command is changed during axis movement.

( 4 ) Related Parameters

[ a ] Setting Parameters

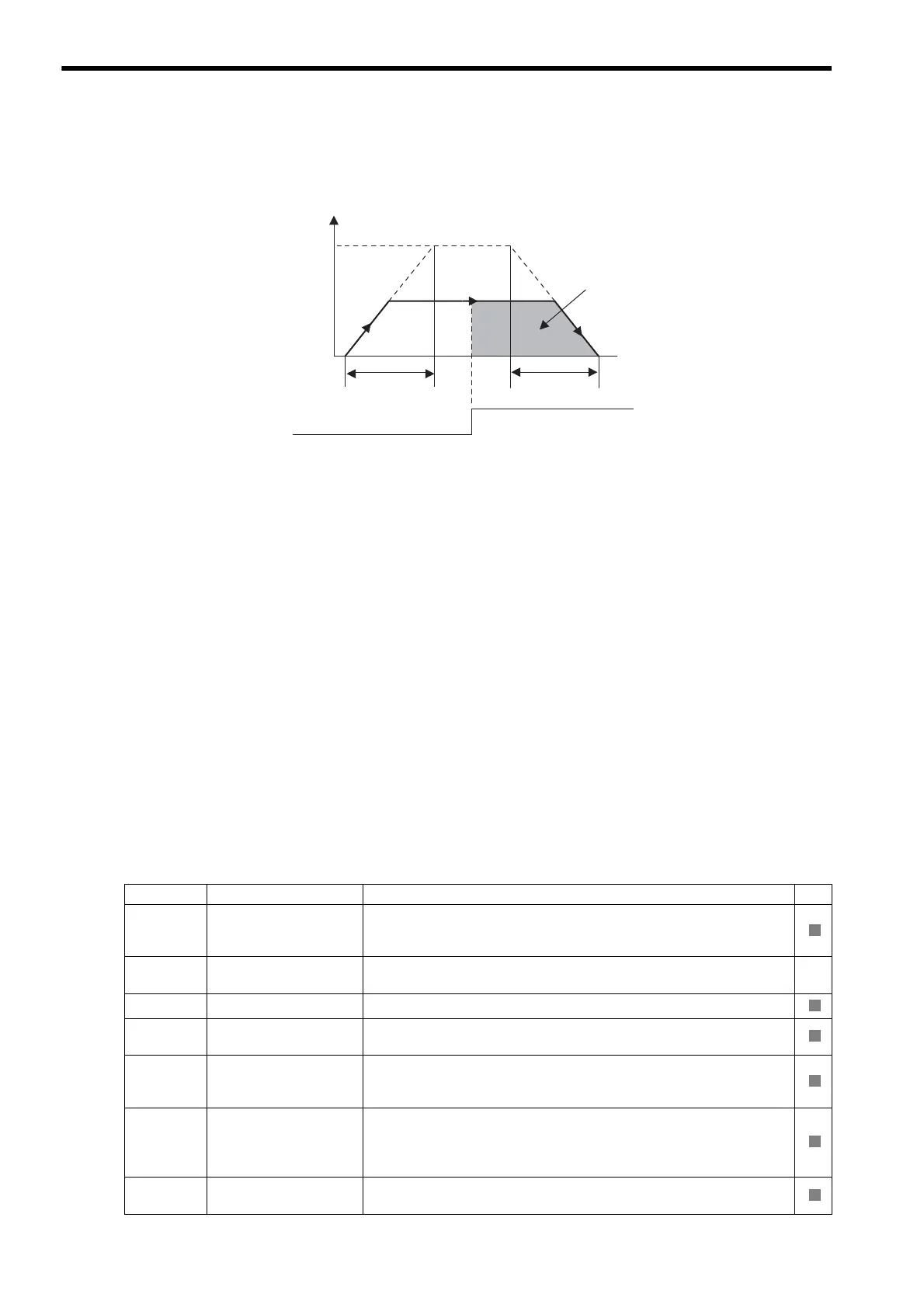

Speed

(%)

(100%)

0

Time (t)

Straight line deceleration time constant

Rated speed

Latch signal

(external positioning signal)

Positioning

speed

External positioning

final travel distance

Straight line acceleration time constant

EX_POSING Operating Pattern

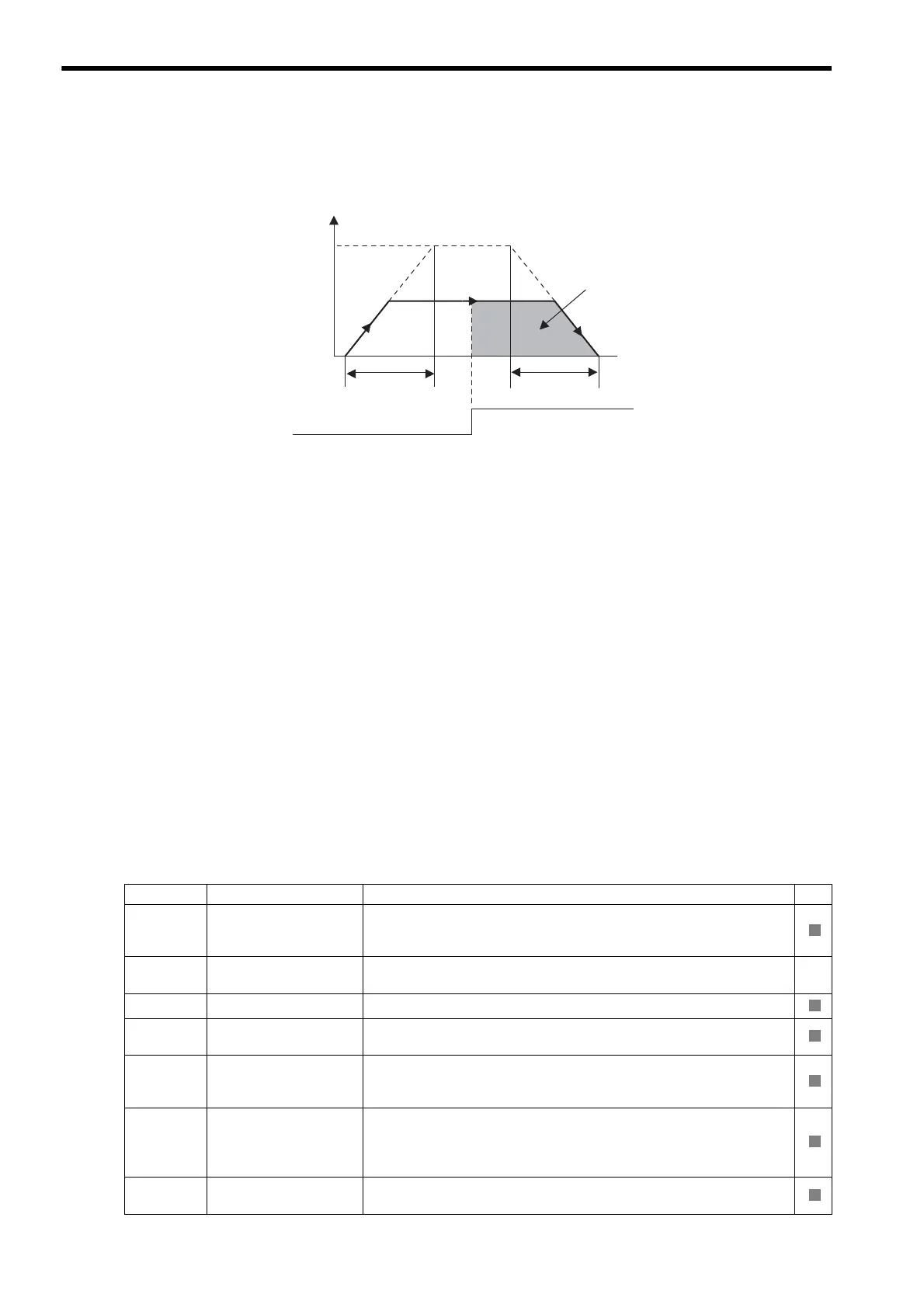

Parameter Name Setting SVR

OW00

Bit 0

Servo ON

Turn the power to the Servomotor ON and OFF.

1: Power ON to Servomotor, 0: Power OFF to Servomotor

Turn ON the power before setting the Motion Command (OW08) to 2.

OW01

Bit 3

Speed Loop

P/PI Switch

Switch the speed control loop between PI control and P control.

0: PI control, 1: P control

−

OW03 Function Setting 1

Set the speed unit, acceleration/deceleration units, and filter type.

OW04 Function Setting 2

Set the external positioning signal.

2: phase-C pulse, 3: /EXT1, 4: /EXT2, 5: /EXT3

OW08 Motion Command

The positioning starts when this parameter is set to 2.

The operation will be canceled if this parameter is set to 0 during EX_POSING

command execution.

OW09

Bit 0

Holds a Command

The axis will decelerate to a stop if this bit is set to 1 during execution of

EX_POSING command execution.

The positioning will restart if this bit is reset to 0 when a command is being

held.

OW09

Bit 1

Interrupt a Command

The axis will decelerate to a stop if this bit is set to 1 during EX_POSING com-

mand execution.

Loading...

Loading...