6.4 Motion Subcommand Details

6.4.3 Write User Constant (PRM_WR)

6-105

6.4.3 Write User Constant (PRM_WR)

The PRM_WR command writes the setting of the SERVOPACK parameter using the specified parameter number,

parameter size, and setting data. The write destination is in the SERVOPACK's RAM.

This command will end with a Command Error Completed Status if it is executed with a communication method

other than MECHATROLINK-II 32-byte Mode.

( 1 ) Executing/Operating Procedure

1.

Check to see if all the following conditions are satisfied.

2.

Set OW0A to 2 to execute the PRM_WR motion subcommand.

The PRM_WR command will write the SERVOPACK parameter.

IW0A will be 2 during command execution.

IW0B, bit 0 will turn ON during the command processing and will turn OFF when the command processing

has been completed.

3.

Set OW0A to 0 to execute the NOP motion command and then complete the writing operation.

( 2 ) Related Parameters

[ a ] Setting Parameters

[ b ] Monitoring Parameters

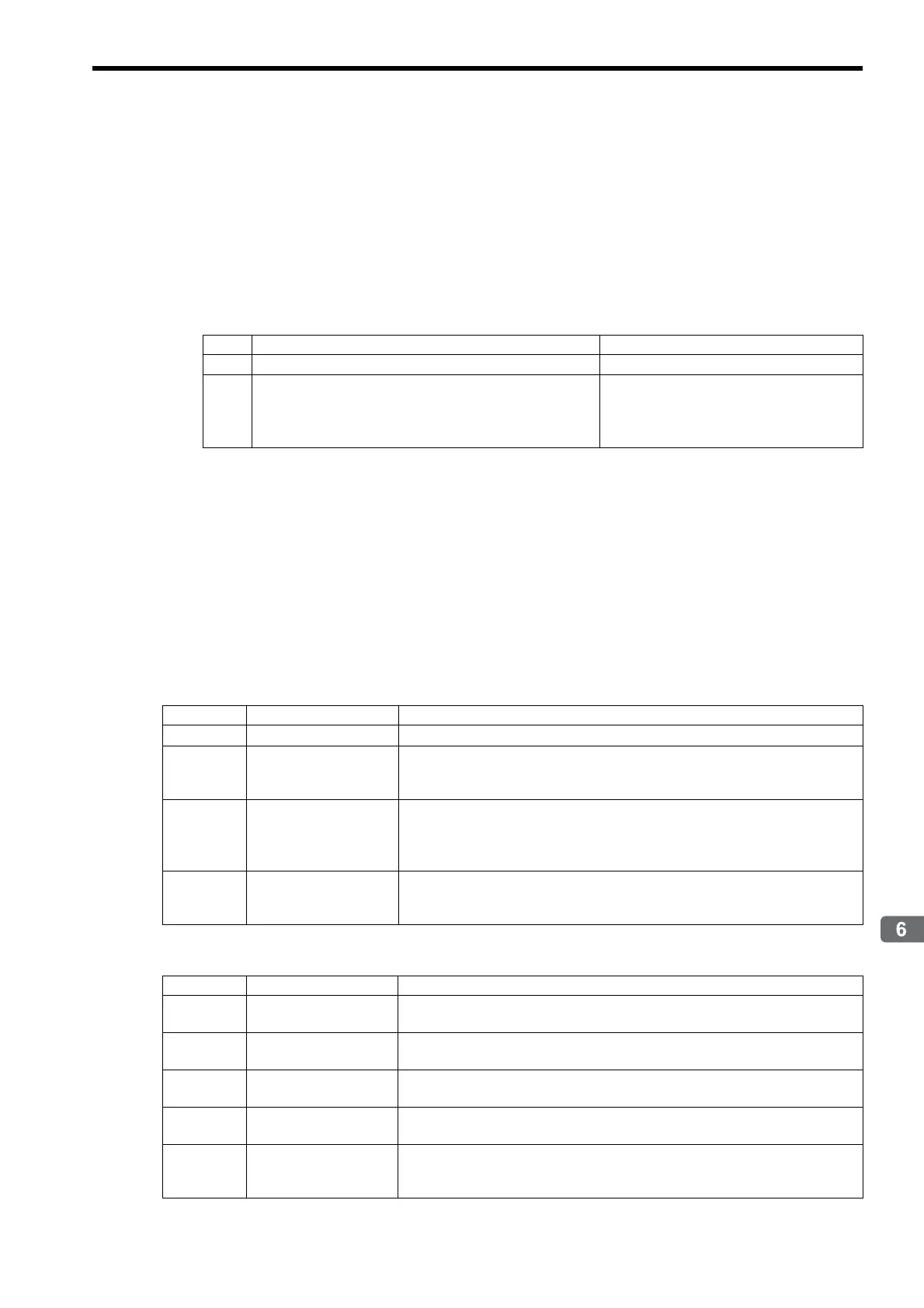

No. Execution Conditions Confirmation Method

1 Motion subcommand execution has been completed. IW0A is 0 and IW0B, bit 0 is OFF.

2

The OW

54, OW

55, and OL

56 settings have

been completed.

Refer to 6.4.3 ( 1 ) [ a ] Setting Parameters below for

details.

−

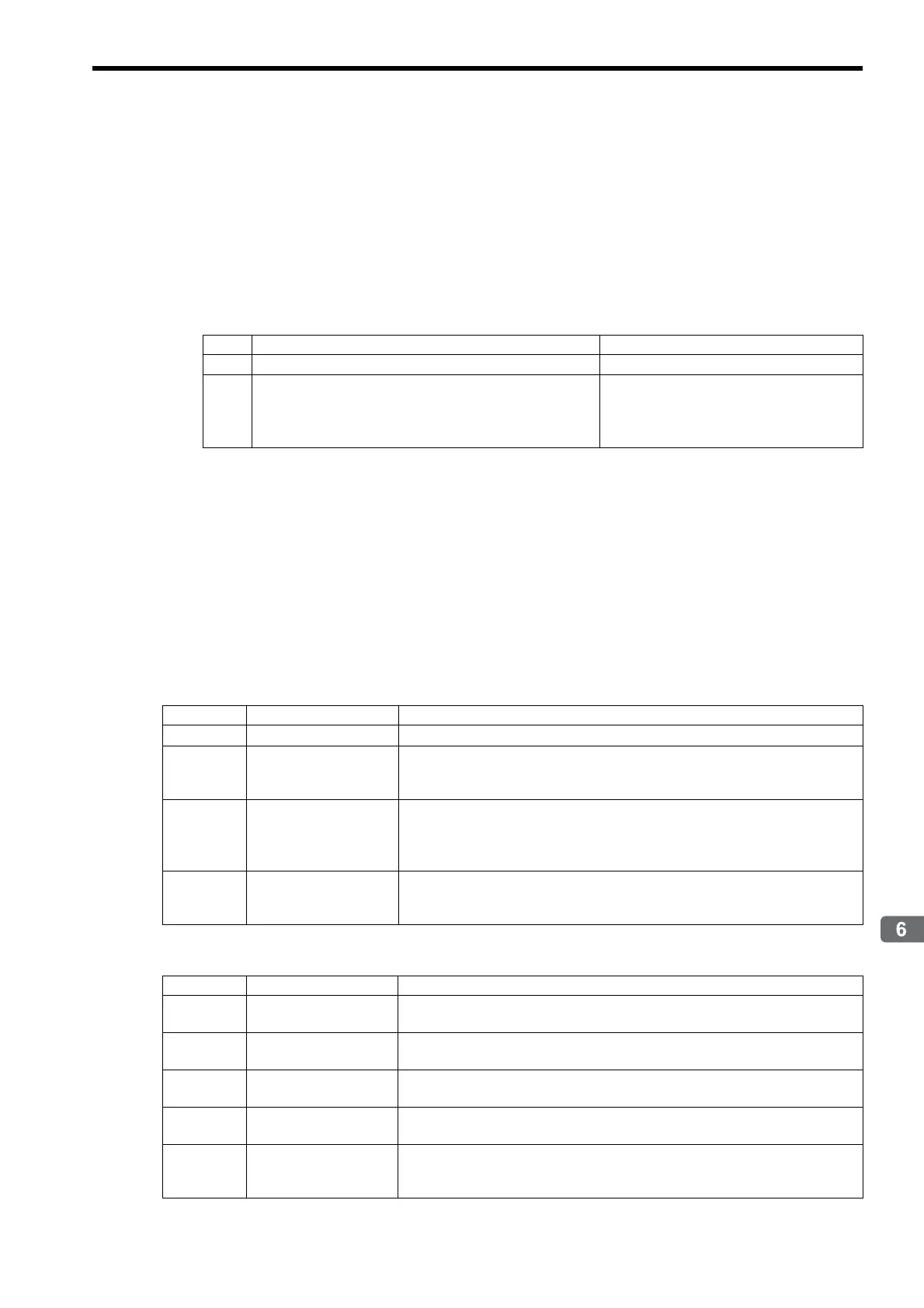

Parameter Name Setting Contents

OW0A Motion Subcommand

The SERVOPACK parameter is written when this parameter is set to 2.

OW54

Servo Driver for Assis-

tance User Constant

No.

Set the number of the SERVOPACK parameter to be written.

OW55

Servo Driver for Assis-

tance User Constant

Size

Set the size of the SERVOPACK parameter to be written.

Set the size in words.

The SERVOPACK’s user manual lists the size in bytes, so those values

must be converted to words.

OL56

Servo Driver for Assis-

tance User Constant

Set Point

Set the set value for the SERVOPACK parameter to be written.

Parameter Name Monitoring Contents

IW0A

Motion Subcommand

Response Code

Indicates the motion subcommand that is being executed.

The response code is 2 during PRM_WR command execution.

IW0B

Bit 0

Command Execution

Flag

Turns ON during PRM_WR command execution and turns OFF when execution has

been completed.

IW0B

Bit 3

Command Error

Completed Status

Turns ON if an error occurs during PRM_WR command execution.

Turns OFF when another command is executed.

IW0B

Bit 8

Command Execution

Completed

Turns ON when PRM_WR command execution has been completed.

IW37

Supplementary Servo

Driver User Constant

No.

Stores the parameter number of the SERVOPACK parameter that was written.

Loading...

Loading...