6.2 Motion Command Details

6.2.11 Change Filter Time Constant (SCC)

6-58

6.2.11 Change Filter Time Constant (SCC)

The SCC command transfers the setting of the Filter Time Constant (motion setting parameter OW3A) to the Mov-

ing Average Time or Exponential Acceleration/Deceleration Time Constant in the SERVOPACK and enables the set-

ting.

Always execute the CHG_FILTER command before executing the SCC command. The setting of the servo parame-

ter to be transferred will depend on the set filter type.

MECHATROLINK-II has a function that automatically updates setting parameters if a parameter changes. There is

no need to execute the SCC command with this function. For details, refer to bit A (User Constants Self-writing

Function) in 4.4.1 ( 2 ) Function Selection 1.

( 1 ) Executing/Operating Procedure

1.

Check to see if all the following conditions are satisfied.

2.

Set OW08 to 12 to execute the SCC motion command.

The parameter to which the value of OW3A is transferred will depend on the set filter type:

Without filter or with moving average filter: Moving Average Time

With exponential acceleration/deceleration filter: Exponential Acceleration/Deceleration Time Constant

IW08 will be 12 during command execution.

IW09, bit 0 will turn ON during the command processing and will turn OFF when the processing has been

completed.

3.

Set OW08 to 0 to execute the NOP motion command and then complete the change of the linear

deceleration time constant.

( 2 ) Holding and Aborting

The Holds a Command bit (OW09, bit 0) and the Interrupt a Command bit (OW09, bit 1) cannot be used.

( 3 ) Related Parameters

[ a ] Setting Parameters

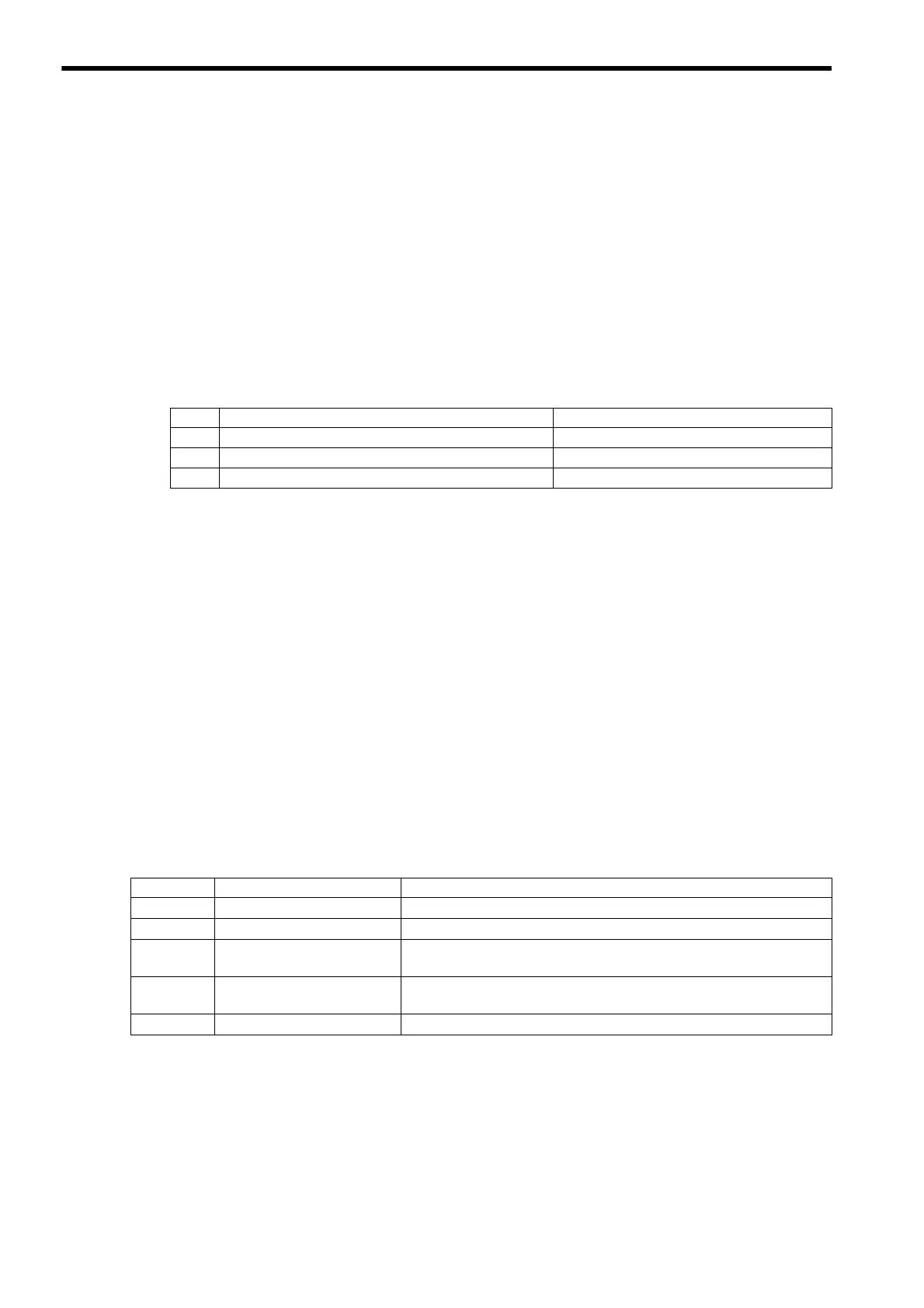

No. Execution Conditions Confirmation Method

1 There are no alarms. Both IL02 and IL04 are 0.

2 Pulse distribution has been completed for the SERVOPACK. IW0C, bit 0 is ON.

3 Motion command execution has been completed. IW08 is 0 and IW09, bit 0 is OFF.

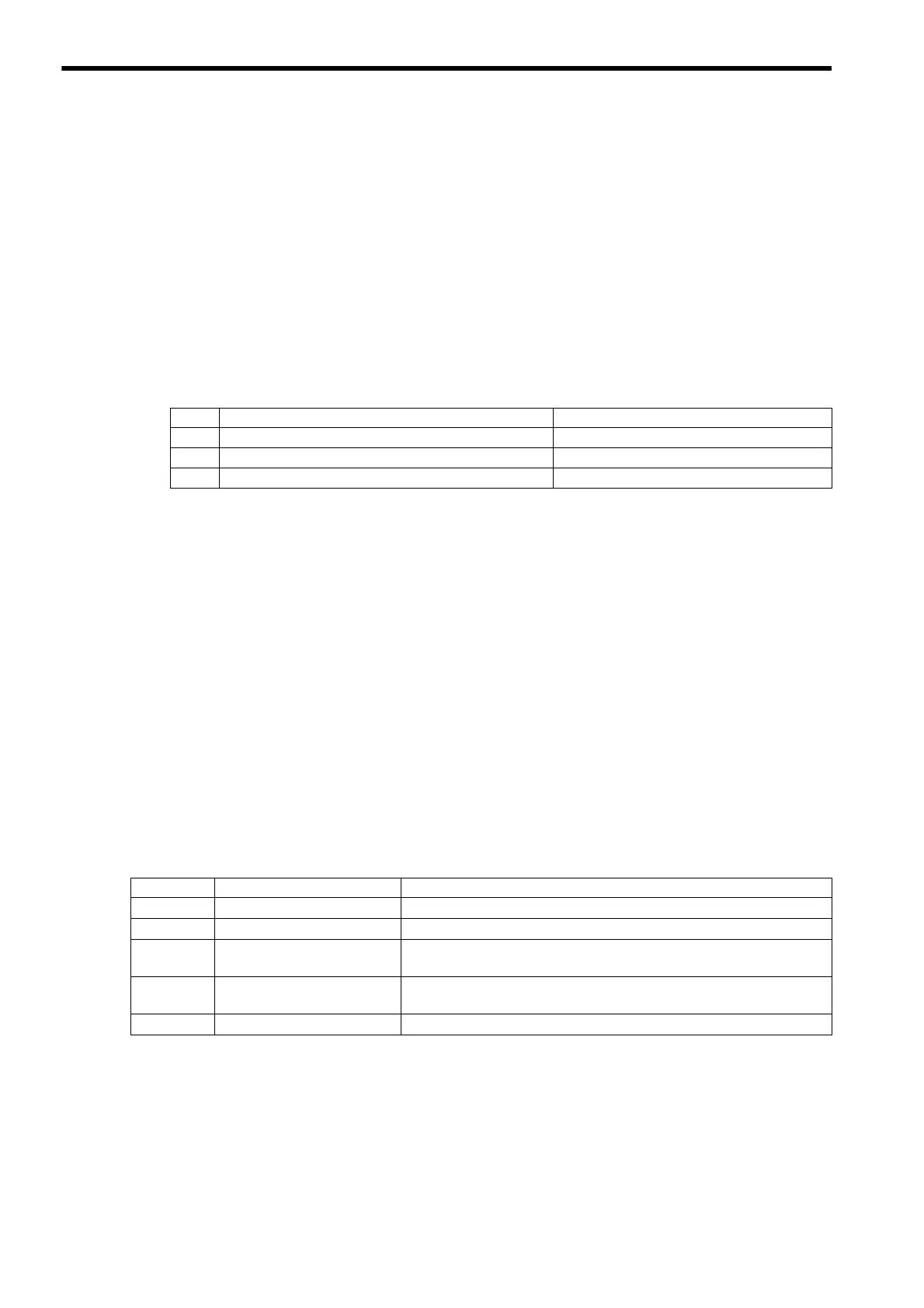

Parameter Name Setting

OW03 Function Setting 1

Set the speed unit, acceleration/deceleration units, and filter type.

OW08 Motion Command

The filter time constant is changed when this parameter is set to 12.

OW09

Bit 0

Holds a Command

This parameter is ignored for SCC command.

OW09

Bit 1

Interrupt a Command

This parameter is ignored for SCC command.

OW3A Filter Time Constant

Set the filter time constant for acceleration/deceleration.

Loading...

Loading...