6.2 Motion Command Details

6.2.23 Torque /Thrust Reference (TRQ)

6-86

( 3 ) Aborting

The torque control mode can be canceled by aborting execution of a command. A command is aborted by setting the

Interrupt a Command Abort bit (OW09 Bit1) to 1.

• Set the Interrupt a Command bit (OW09, bit 1) to 1. The axis will decelerate to a stop. The abort process-

ing will be completed when the axis has decelerated to a stop.

• The torque control mode operation will restart if the Interrupt a Command bit (OW09, bit 1) is reset to 0

during abort processing.

• This type of operation will also be performed if the motion command is changed during operation with torque

control mode.

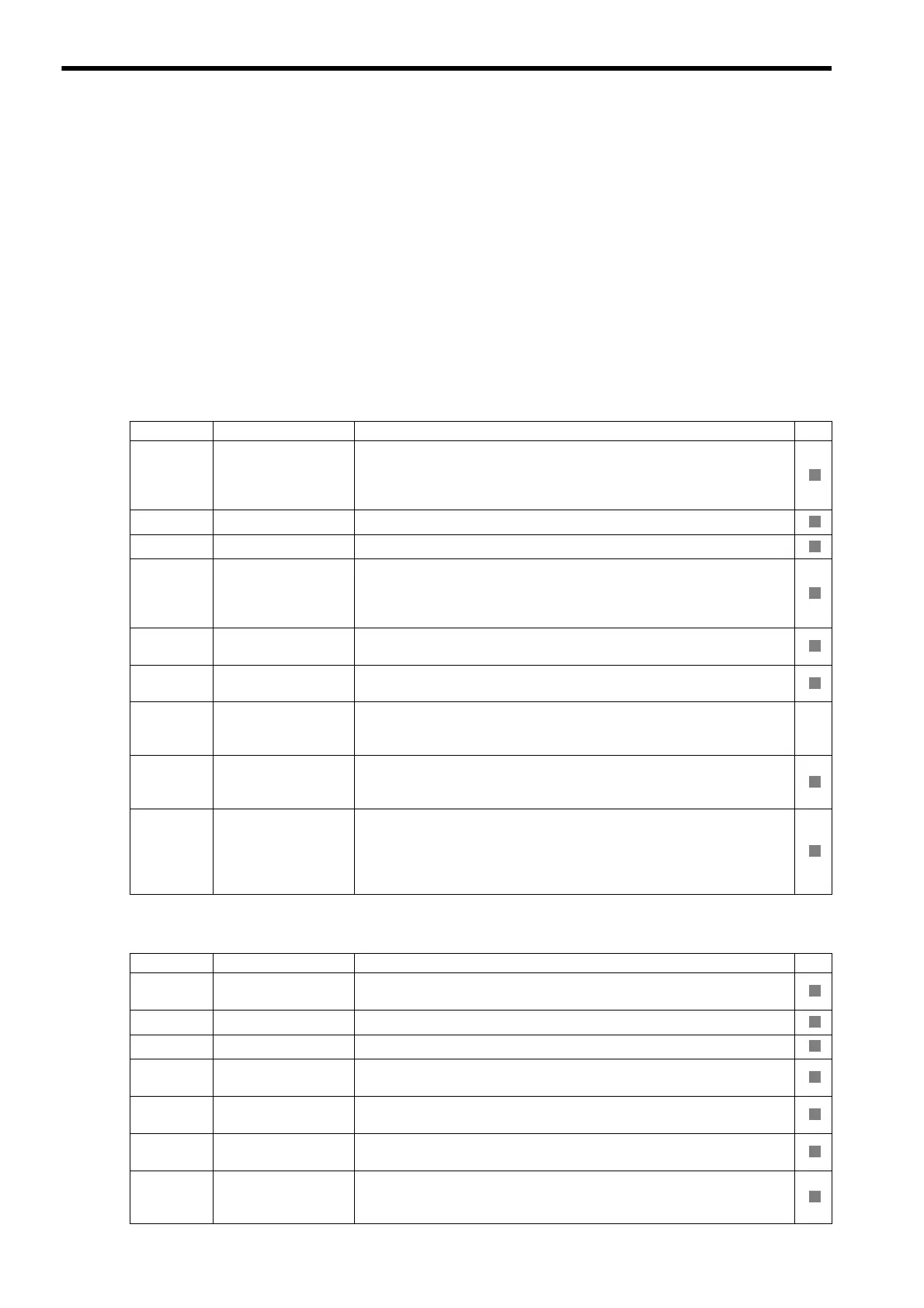

( 4 ) Related Parameters

[ a ] Setting Parameters

[ b ] Monitoring Parameters

Parameter Name Setting SVR

OW00

Bit 0

Servo ON

Turn the power to the Servomotor ON and OFF.

1: Power ON to Servomotor, 0: Power OFF to Servomotor

Motor torque will start to rotate when the Servo is turned ON after switching to

Torque Control Mode.

OW03 Function Setting 1

Set the unit for torque reference.

OW08 Motion Command

The mode is changed to torque control when this parameter is set to 24.

OW09

Bit 0

Holds a Command

The axis will stop when this bit is changed to ON while the axis is moving for the

torque reference.

The axis will start moving again when this bit is changed to OFF while the com-

mand is being held.

OW09

Bit 1

Interrupt a Command

A deceleration stop is performed when this bit set to 1 during operation.

OL0C Torque Reference

Set the torque reference. This setting can be changed during operation.

The unit depends on the Function Setting 1 (OW03, bits C to F).

OW0E

Speed Limit Setting at

the Torque/Thrust

Reference

Set the speed limit for torque references. The speed limit is set as a percentage of

the rated speed.

−

OL38

Straight Line Deceler-

ation/Deceleration

Time Constant

Set the rate of deceleration or deceleration time for positioning.

OW3A Filter Time Constant

Set the acceleration/deceleration filter time constant. Exponential acceleration/

deceleration or a moving average filter can be selected in the Function Setting 1

(OW03, bits 8 to B).

Change the setting only after pulse distribution has been completed for the com-

mand (IW0C, bit 0 is ON).

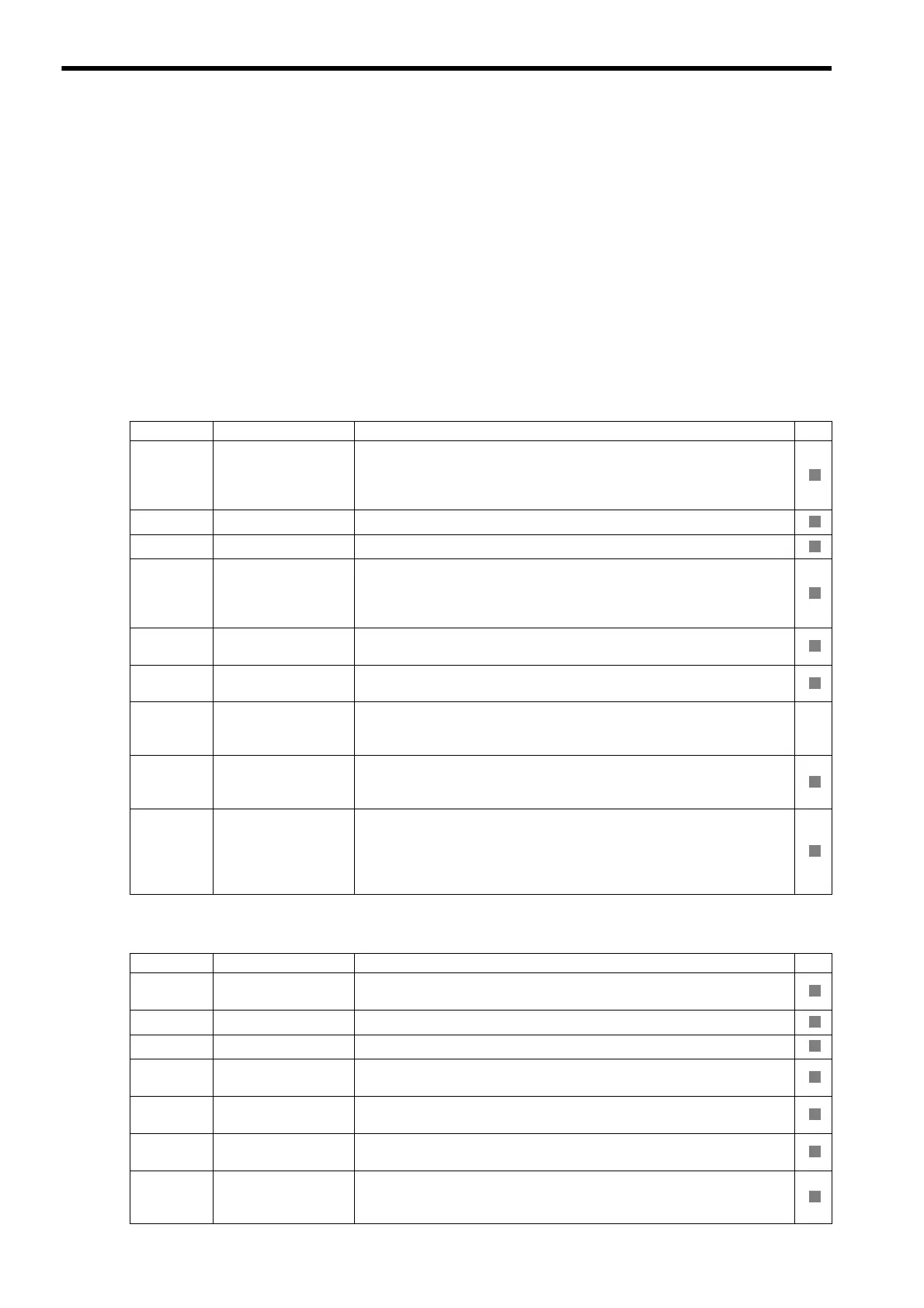

Parameter Name Monitor Contents SVR

IW00

Bit 1

Running (At Servo

ON)

Indicates the Servo ON status.

ON: Power supplied to Servomotor, OFF: Power not supplied to Servomotor

IL02 Warning

Stores the most current warning.

IL04 Alarm

Stores the most current alarm.

IW08

Motion Command Re-

sponse Code

Indicates the motion command that is being executed.

The response code will be 24 during TRQ command execution.

IW09

Bit 0

Command Execution

Flag

Turns ON when abort processing is being performed for TRQ command. Turns

OFF when abort processing has been completed.

IW09

Bit 1

Command Hold

Completed

Always OFF for TRQ command.

IW09

Bit 3

Command Error

Completed Status

Turns ON if an error occurs during TRQ command execution.

The axis will decelerate to a stop if it is operating. Turns OFF when another com-

mand is executed.

Loading...

Loading...