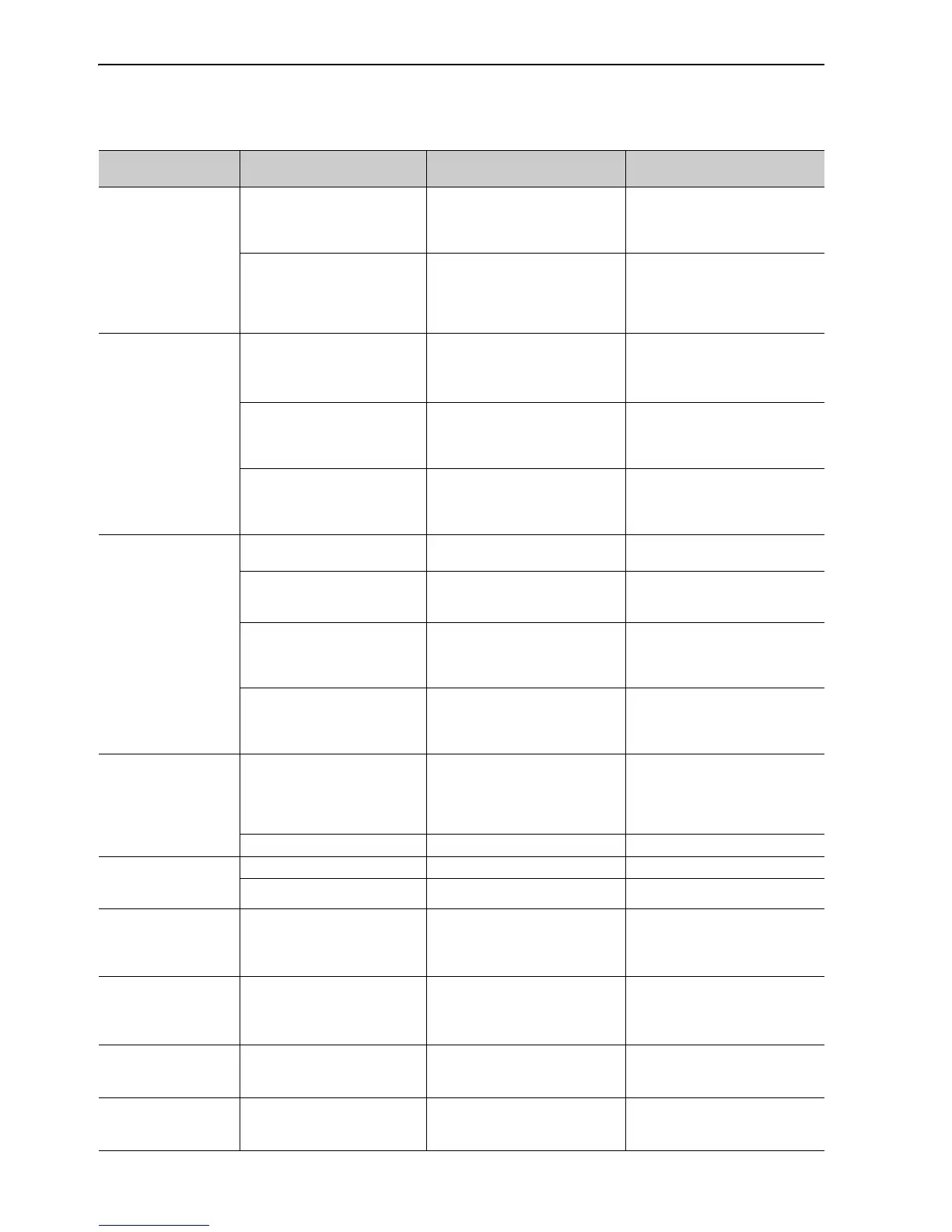

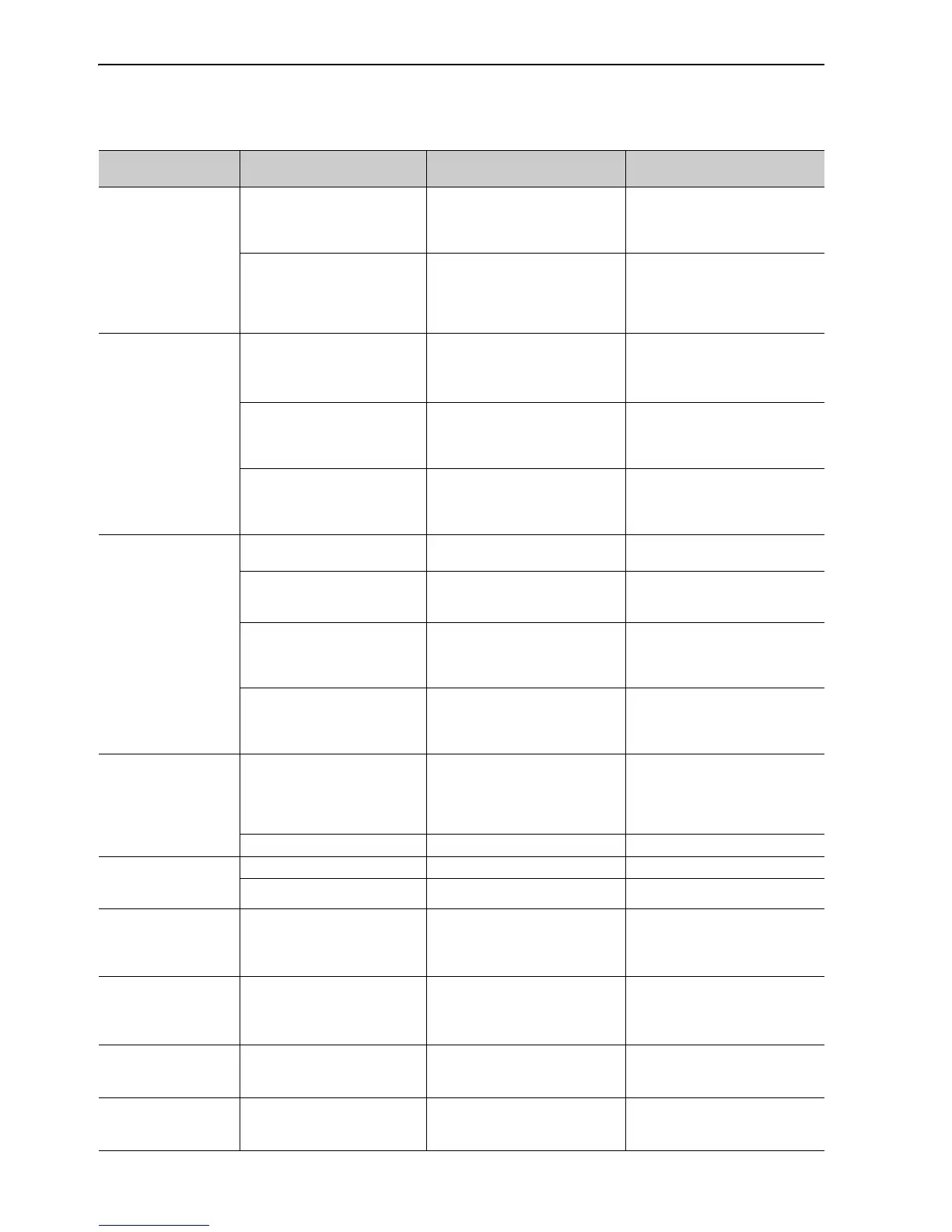

11 Inspection, Maintenance, and Troubleshooting

11.2.3 Troubleshooting of the Servo Drive Alarms

11-24

A.840:

Encoder Data Error

(Detected on the

encoder.)

Encoder failure −

Turn the power supply OFF and

then ON again. If the alarm still

occurs, the servomotor may be

faulty. Replace the servomotor.

Malfunction of encoder because

of noise interference, etc.

−

Correct the wiring around the

encoder by separating the encoder

cable from the servomotor main cir-

cuit cable or by checking the

grounding and other wiring.

A.850:

Encoder Overspeed

(Detected when the con-

trol power supply was

turned ON.)

(Detected on the

encoder.)

The servomotor was running at

200 min

-1

or higher when the

control power supply was turned

ON.

Check the speed monitor in

SigmaWin for the Σ-V-SD (MT)

to see the servomotor speed

when the power is turned ON.

Reduce the servomotor speed to a

value less than 200 min

-1

, and turn

ON the control power supply.

Encoder failure −

Turn the power supply OFF and

then ON again. If the alarm still

occurs, the servomotor may be

faulty. Replace the servomotor.

SERVOPACK failure −

Turn the power supply OFF and

then ON again. If the alarm still

occurs, the SERVOPACK may be

faulty. Replace the SERVOPACK.

A.860:

Encoder Overheated

(Only when an absolute

encoder is connected.)

(Detected on the

encoder.)

The ambient temperature around

the servomotor is too high.

Measure the ambient temperature

around the servomotor.

The ambient temperature must be

40°C or less.

The servomotor load is greater

than the rated load.

Check the accumulated load ratio

monitor in SigmaWin for the Σ-V-

SD (MT) to see the load.

Set the servomotor load within the

specified range.

Encoder failure −

Turn the power supply OFF and

then ON again. If the alarm still

occurs, the servomotor may be

faulty. Replace the servomotor.

SERVOPACK failure −

Turn the power supply OFF and

then ON again. If the alarm still

occurs, the SERVOPACK may be

faulty. Replace the SERVOPACK.

A.8A0:

External Encoder

Error of Scale

Setting of the zero point position

of absolute external scale failed

because the servomotor rotated.

Before setting the zero point posi-

tion, use the fully-closed feedback

counter monitor in SigmaWin for

the Σ-V-SD (MT) to confirm that

the servomotor is not rotating.

Make the settings so that the servo-

motor will be stopped while setting

the zero point position.

External encoder failure − Replace the external encoder.

A.8A1:

External Encoder

Error of Module

External encoder failure − Replace the external encoder.

Serial converter unit failure − Replace the serial converter unit.

A.8A2:

External Encoder

Error of Sensor

(Incremental)

External encoder failure − Replace the external encoder.

A.8A3:

External Encoder

Error of Position

(Absolute)

Absolute external encoder failure −

The absolute external encoder may

be faulty. Refer to the encoder man-

ufacture’s instruction manual for

corrective actions.

A.8A5:

External Encoder

Overspeed

The overspeed from the external

encoder occurred.

−

Repair or replace the external

encoder.

A.8A6:

External Encoder

Overheated

The overheat from the external

encoder occurred.

−

Repair or replace the

external

encoder.

(cont’d)

Alarm:

Alarm Name

Cause Investigative Actions Corrective Actions

Loading...

Loading...