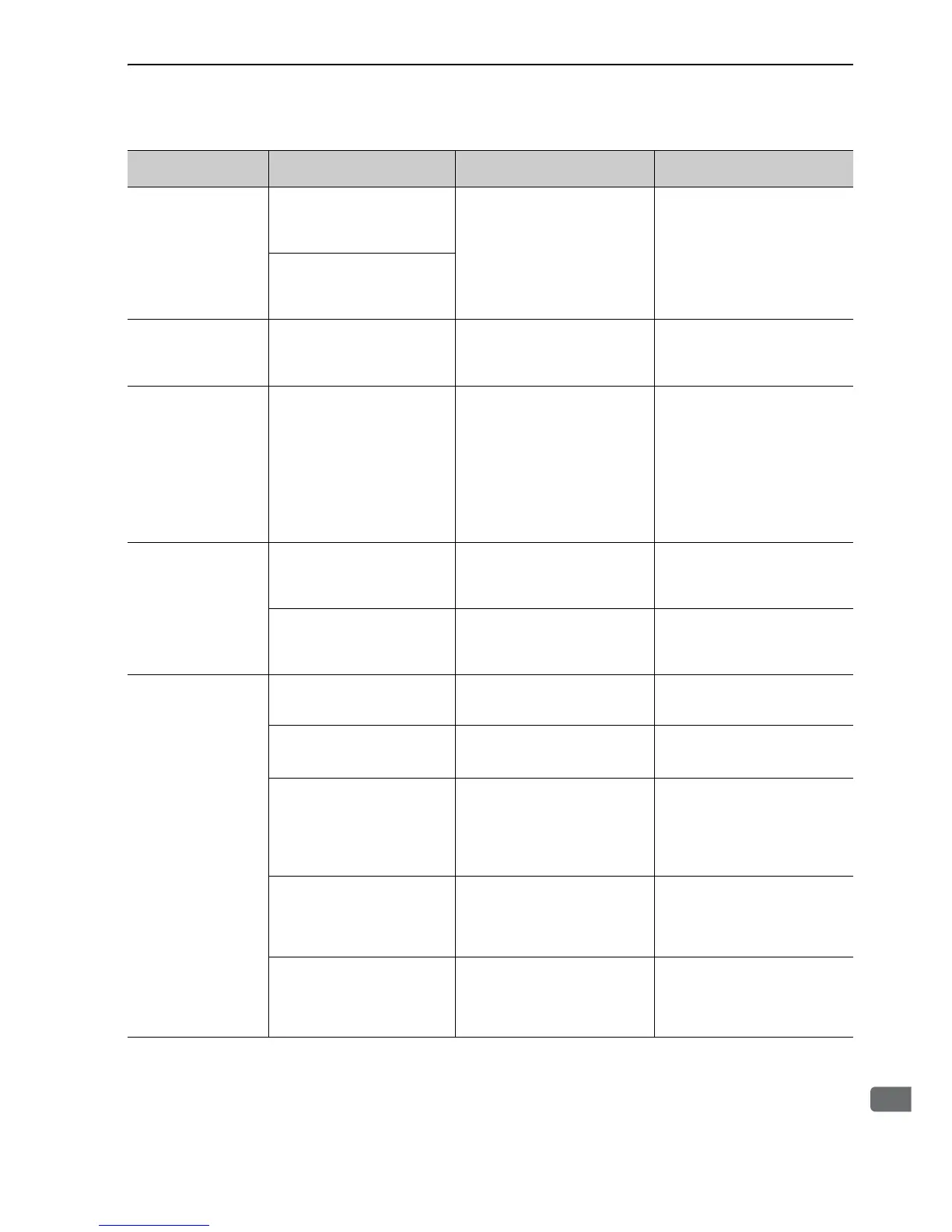

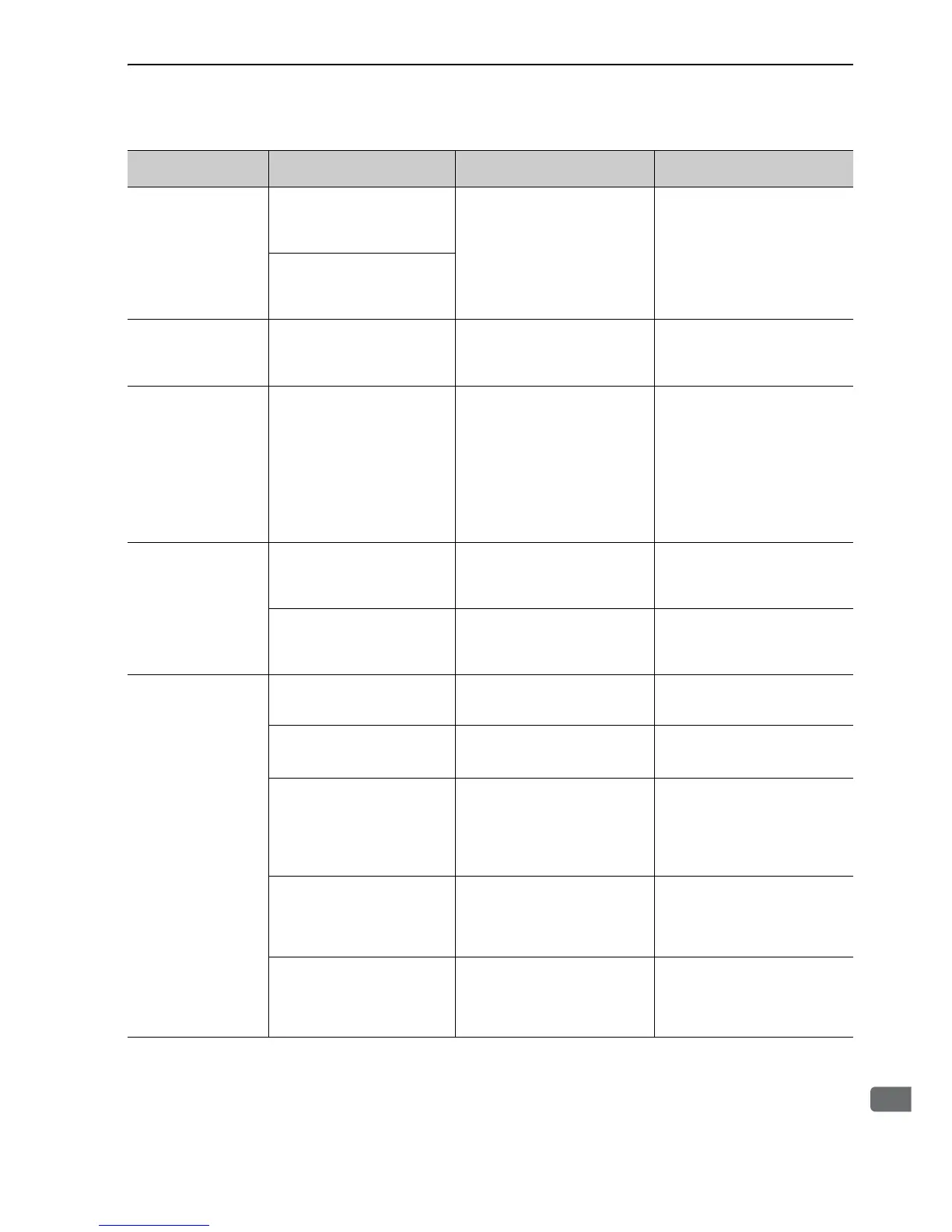

A.C52:

Polarity Detection

Uncompleted

An attempt was made to detect

the magnetic pole for the high-

speed winding (for motors with a

winding selection).

−

Perform magnetic pole detection for

the low-speed winding.

An attempt was made to detect

the magnetic pole when changing

the winding (for motors with a

winding selection).

C53:

Out of Range for

Polarity Detection

The travel distance during mag-

netic pole detection exceeded the

magnetic pole detection travel

range in Pn494.

−

Increase the magnetic pole detec-

tion travel range in Pn494.

Increase the magnetic pole detec-

tion speed loop gain in Pn481.

C54:

Polarity Detection

Error 2

The motor’s electrical angle dur-

ing magnetic pole detection con-

firmation exceeded the magnetic

pole detection allowable devia-

tion range in Pn498.

−

Increase the magnetic pole detec-

tion confirmation torque in Pn495.

Increase the magnetic pole detec-

tion allowable deviation range in

Pn498 (however, a motor overheat-

ing alarm or overload alarm may

occur).

Reduce the external force on the

motor’s stator to about 10% or less

of the motor’s rated torque.

A.C80:

Absolute Encoder

Clear Error

(Multiturn Limit Setting

Error)

Encoder failure −

Turn the power supply OFF and

then ON again. If the alarm still

occurs, the servomotor may be

faulty. Replace the servomotor.

SERVOPACK failure −

Turn the power supply OFF and

then ON again. If the alarm still

occurs, the SERVOPACK may be

faulty. Replace the SERVOPACK.

A.C90:

Encoder

Communications Error

Contact fault of encoder connec-

tor or incorrect encoder wiring.

Check the encoder connector con-

tact status.

Re-insert the encoder connector and

confirm that the encoder is correctly

wired.

Encoder cable disconnection or

short-circuit.

Or, incorrect cable impedance.

Check the encoder cable.

Use the encoder cable with the

specified rating.

Corrosion caused by improper

temperature, humidity, or gas

Short-circuit caused by intrusion

of water drops or cutting oil

Connector contact fault caused by

vibration.

Check the operating environment.

Improve the operating environmen-

tal conditions, and replace the cable.

If the alarm still occurs, replace the

SERVOPACK.

Malfunction caused by noise

interference.

−

Correct the wiring around the

encoder to avoid noise interference

(Separate the encoder cable from

the servomotor main circuit cable,

improve grounding, etc.)

SERVOPACK failure −

Connect the servomotor to another

SERVOPACK, and turn ON the

control power. If no alarm occurs,

the SERVOPACK may be faulty.

Replace the SERVOPACK.

(cont’d)

Alarm:

Alarm Name

Cause Investigative Actions Corrective Actions

Loading...

Loading...