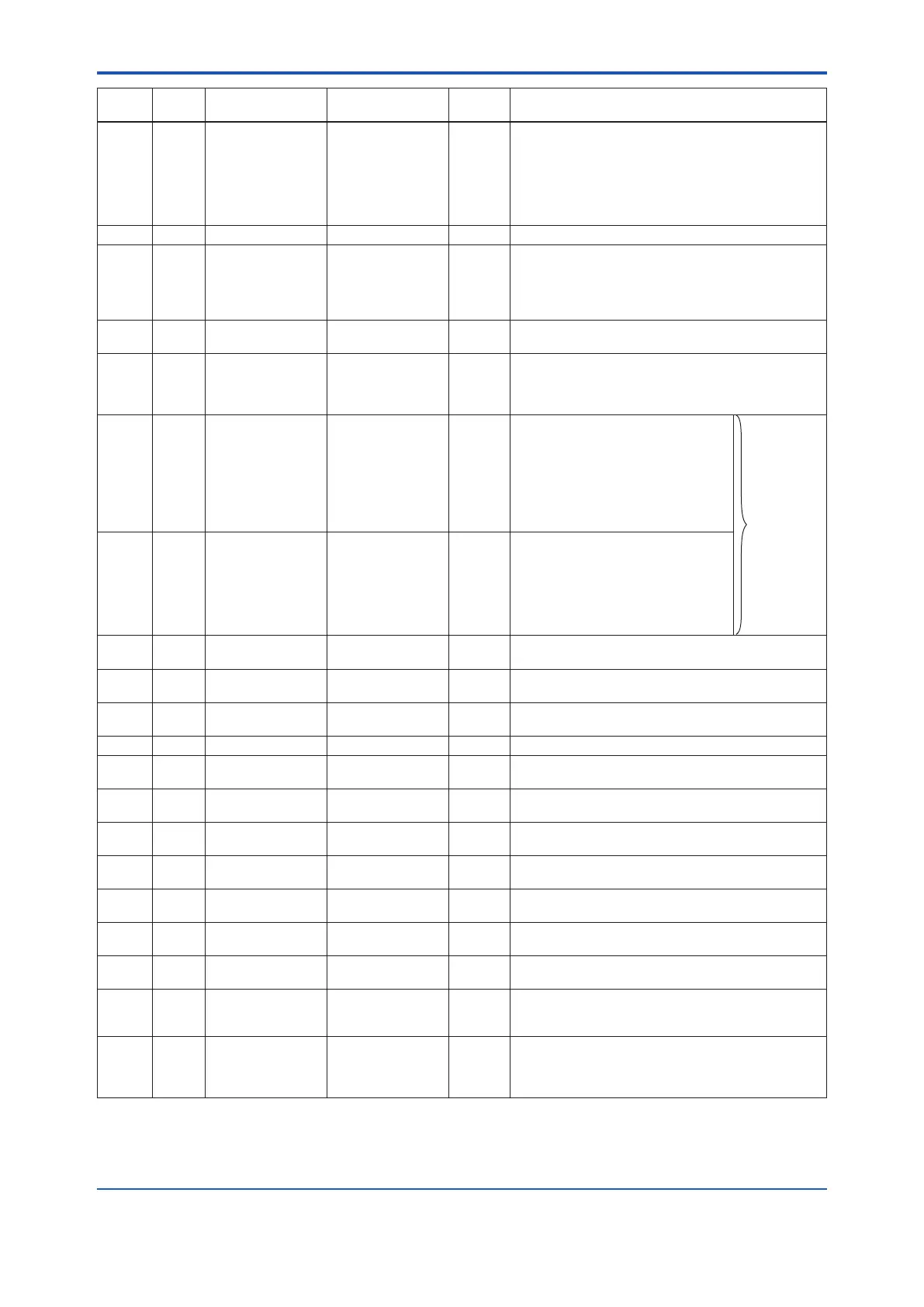

<APPENDIX 1. LIST OF PARAMETERS FOR EACH BLOCK OF digitalYEWFLO>

A1-8

IM 01F06F00-01EN

Relative

Index

Index Parameter Name Factory Default

Write

Mode

Explanation

43 2043 LIMSW_2 _

HYSTERESIS

0 O/S Sets the hysteresis of limit switch 2 to be applied

for resetting the LIMSW_2_VALUE_D to OFF after

LIMSW_2_TARGET went beyond LIMSW_2_SETPOINT

and LIMSW_2_VALUE_D turned ON (when used as a

high-limit switch), or after LIMSW_2_TARGET went below

LIMSW_2_SETPOINT and LIMSW_2_VALUE_D turned

ON (when used as a low-limit switch).

44 2044 LIMSW_2_UNIT — — Indicates the unit set in LIMSW_2_TARGET.

45 2045 ALARM _PERFORM 0x1070 AUTO A series of bits, each of which works as a switch to

enable and disable specic alarm(s); write zeros to the

respective bits in this parameter to disable desired alarms.

(For details, read APPENDIX 3 "OPERATION OF EACH

PARAMETER IN FAILURE MODE.")

46 2046 ARITHMETIC

_BLOCK

1 (Available) — Indicates whether the arithmetic block is available.

47 2047 SENSOR_STATUS — — Indicates whether the ow detector has the built-in

temperature sensor:

1 = Standard

2 = Built-in Temp. Sensor

48 2048 THERMOMETER

_FUNCTION

1 (Monitor only)

(Note 5)

O/S Selects the usage of the thermometer

function:

1 = Monitor only

2 = Saturated steam

3 = Superheat steam

4 = GAS: STD/Normal

5 = LIQUID: Mass

6 = Not use

(For details,

read

Section 6.2

"Transducer

Block

Parameters.")

49 2049 FLUID_TYPE 1 (LIQUID: Volume)

(Note 5)

O/S Selects the type of the measured

process uid:

1 = LIQUID: Volume

2 = GAS/STEAM: Volume

3 = LIQUID: Mass

4 = GAS/STEAM: Mass

5 = GAS: STD/Normal

50 2050 TEMPERATURE

_UNIT

°C (1001) (Note 5) O/S Selects the unit of temperature.

51 2051 PROCESS_TEMP 15 (Note 5) O/S Sets the normal operating temperature of the process.

Setting range: –999.9 to 999.9

52 2052 BASE_TEMP 15 (Note 5) O/S Sets the temperature under the standard conditions of the

process. Setting range: from –999.9 to 999.9

53 2053 DENSITY_UNIT Kg/m

3

(1097) (Note 5) O/S Selects the unit of density.

54 2054 PROCESS _

DENSITY

1024 (Note 5) O/S Sets the density of the process uid under the normal

operating conditions. Setting range: 0.00001 to 32000

55 2055 BASE_DENSITY 1024 (Note 5) O/S Sets the density of the process uid under the standard

operating conditions. Setting range: 0.00001 to 32000

56 2056 PRESSURE_UNIT MPaa (1545) (Note 5) O/S Selects the unit of pressure between 1545 (= MPaa) and

1547 (= kPaa).

57 2057 PROCESS _

PRESSURE

0.1013 (Note 5) O/S Sets the normal operating absolute pressure of the

process. Setting range: 0.00001 to 32000

58 2058 BASE _PRESSURE 0.1013 (Note 5) O/S Sets the absolute pressure under the standard conditions

of the process. Setting range: 0.00001 to 32000

59 2059 DEVIATION 1 (Note 5) O/S Sets the deviation factor of the process uid. Setting range:

0.001 to 10.0

60 2060 SECONDARY

_VALUE_FTIME

4 s AUTO Sets the time constant of damping for the temperature

calculation. Setting range: 0 to 99 s

61 2061 CABLE_LENGTH 0 O/S Sets the length of cable between the ow detector and

remote amplier. Set 0 for an integral type digitalYEWFLO.

Setting range: 0 to 30 (meters)

62 2062 FIRST_TEMP

_COEF

0 O/S Sets the rst temperature coefcient for the density

compensation of a liquid.

Setting range: –32000 to 32000

Unit: 1/TEMP_UNIT

Loading...

Loading...