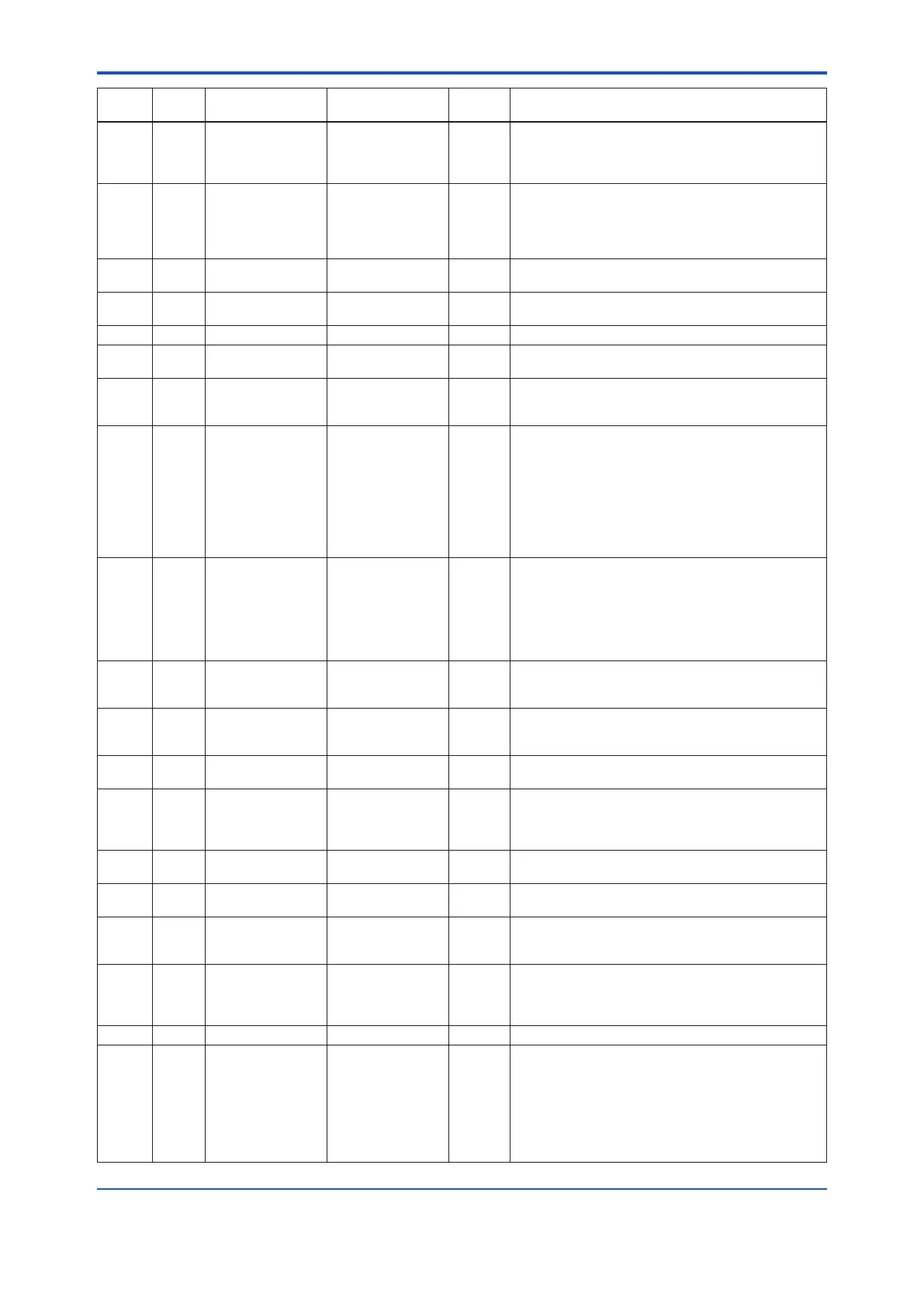

<APPENDIX 1. LIST OF PARAMETERS FOR EACH BLOCK OF digitalYEWFLO>

A1-9

IM 01F06F00-01EN

Relative

Index

Index Parameter Name Factory Default

Write

Mode

Explanation

63 2063 SECOND_TEMP

_COEF

0 O/S Sets the second temperature coefcient for the density

compensation of a liquid.

Setting range: –32000 to 32000

Unit: 1/TEMP_UNIT^2

64 2064 SIZE_SELECT 25 mm (2) (Note 5) O/S Selects the owmeter size: 1 = 15 mm (1/2 in.); 2 = 25 mm

(1 in.); 3 = 40 mm (1.5 in.); 4 = 50 mm (2 in.); 5 = 80 mm

(3 in.); 6 = 100 mm (4 in.); 7 = 150 mm (6 in.); 8 = 200 mm

(8 in.); 9 = 250 mm (10 in.); 10 = 300 mm (12 in.); 11 =

400 mm (16 in.)

65 2065 BODY_TYPE Standard (1) O/S Selects the owmeter body type: 1 = Standard; 2 = High

Pressure; 3 = Low Flow Unit (1); 4 = Low Flow Unit (2)

66 206 VORTEX _

SENSOR_TYPE

Standard (1) O/S Selects the vortex sensor type: 1 = Standard; 2 = High

Temperature; 3: Low temperature.

67 2067 K_FACTOR_UNIT p/L (1) O/S Selects the unit of the K factor.

68 2068 K_FACTOR 68.6 O/S Sets the K factor of the combined detector at 15°C.

Setting range: 0.00001 to 32000

69 2069 LOW_CUT_FLOW 0.46687 (minimum

gas ow rate for the

size of 25 mm [1 in.])

O/S Sets the low cutoff ow rate level. Setting range: Minimum

ow rate x 0.5 to XD_SCALE.EU_100. The unit selected in

PRIMARY_VALUE_RANGE.Units Index applies.

70 2070 UPPER_DISPLAY

_MODE

1 AUTO Selects the data to be displayed on the upper row of the

LCD indicator:

1 = Flow Rate (%): Instantaneous ow rate as a

percentage

2 = Flow Rate: Instantaneous ow rate in the specied

unit

3 = Temperature (%): Temperature as a percentage (can

only be selected for a mode with the MV option)

4 = Arithmetic Out

71 2071 LOWER_DISPLAY

_MODE

1 AUTO Selects the data to be displayed on the upper row of the

LCD indicator, as follows:

1 = Blank

2 = Total: Totalized ow rate

3 = Temperature: Temperature (can only be selected for

a mode with the MV option)

4 = Integrator Out

72 2072 DISPLAY_CYCLE 1 (500 ms) O/S,

AUTO

Sets the display refresh cycle of the LCD indicator, as a

multiple of 500 milliseconds. Setting range: 1 to 10 (= 0.5

to 5 seconds)

73 2073 USER_ADJUST 1 O/S User-set adjustment factor. The measured ow rate

multiplied by this factor is output. Setting range: 0.00001

to 32000

74 2074 REYNOLDS

_ADJUST

1 (Not Active) O/S Selects whether to activate Reynolds number correction: 1

= Not Active; 2 = Active

75 2075 VISCOSITY _VALUE 1 (Note 5) O/S Sets the viscosity coefcient of the process uid. When

REYNOLDS_ADJUST is set to Active, this parameter

needs to be set since it is used in the Reynolds number

calculation. Setting range: 0.00001 to 32000 [mPa•Pas]

76 2076 GAS_EXPANSION

_FACT

1 (Not Active) O/S Selects whether to activate expansion correction for a

compressible uid: 1 = Not Active; 2 = Active

77 2077 FLOW_ADJUST 1 (Not Active) O/S Selects whether to activate instrument error correction for

a compressible uid: 1 = Not Active; 2 = Active

78 2078 FLOW_ADJ _FREQ 0 O/S Sets the rst to fth breakpoint frequencies for the

instrument error correction in an array format. Setting

range: 0.0 to 32000 (unit is Hz [1077])

79 2079 FLOW_ADJ_DATA 0 O/S Sets the correcting values corresponding to the rst to fth

breakpoint frequencies for the instrument error correction

in an array format. Setting range: –50.00 to 50.00 (unit is

% [1342])

80 2080 TRIGGER_LEVEL 1 O/S Sets the trigger level. Setting range: 0.1 to 20.0

81 2081 NOISE_BALANCE

_MODE

1 (Auto) O/S Indicates the mode of noise balance ratio tuning and

allows tuning to be activated:

1 = Auto: Automatic noise balance mode

2 = Manual: Manual noise balance mode

3 = Tuning at Zero: Setting this value causes noise

balance ratio to be tuned given that the current ow

rate is zero; then after completion of the tuning, the

parameter value reverts to 2 (Manual).

Loading...

Loading...