Appendix

App.-2

IM 11M10A01-01E

2.Installation

The sampling unit is a desktop type and should be installed on a stand near the sampling point.

Note the following when installing the unit.

CAUTION

The unit should be installed in places where:

• Ambienttemperatureisintherangeof0to40Candtemperatureuctuationsareminimal.

• Mechanical vibration is negligible.

• Adequatespaceforinspectionandmaintenance,suchasreplacinglterelement,is

secured.

• The unit should be securely mounted on a stand to prevent its dropping.

• No exposure to rain or water is allowed.

Procedure:

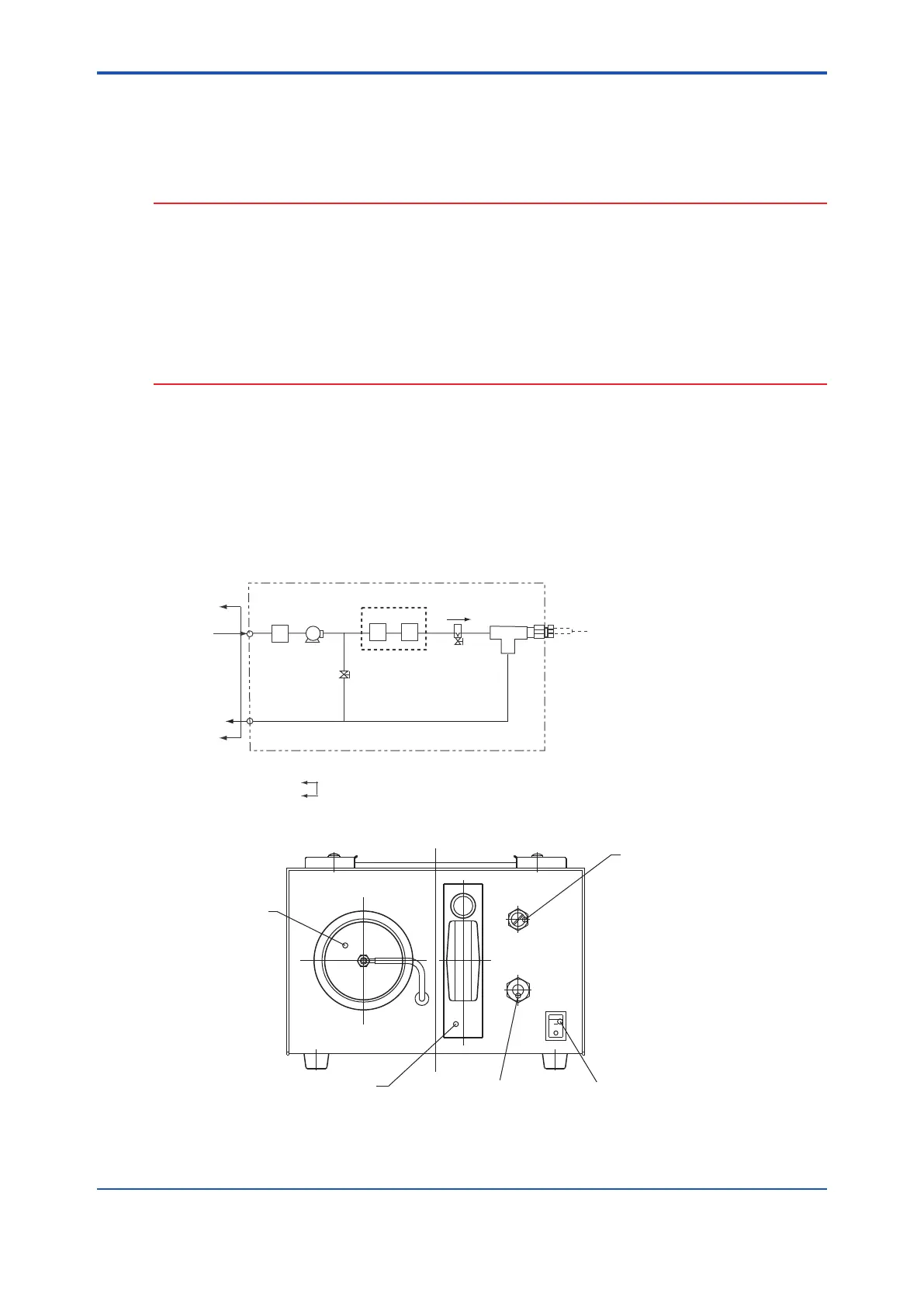

(1) Feed sampling tubing from the sampling point through a stop valve to the sample gas inlet,

GAS IN, with care not to produce gas leakage. The piping connection of the sample gas

inlet is Rc1/4. Use an appropriate joint for this connection.

(2) Feed gas vent tubing from the sampling outlet, GAS OUT, with care not to produce gas

leakage. The piping connection of the sampling gas outlet is Rc1/4. Use an appropriate joint

for his connection.

(3) Insert a power cable to the power connector of the sampling unit.

SENSOR

0.5l/min

AP101E.eps

F2 F3

FM1

V1

F1 PU1

GAS IN

GAS OUT

Note: Piping connection: Rc1/4

: Provided by customer

Figure1. PipingDiagram

AP102.Eeps

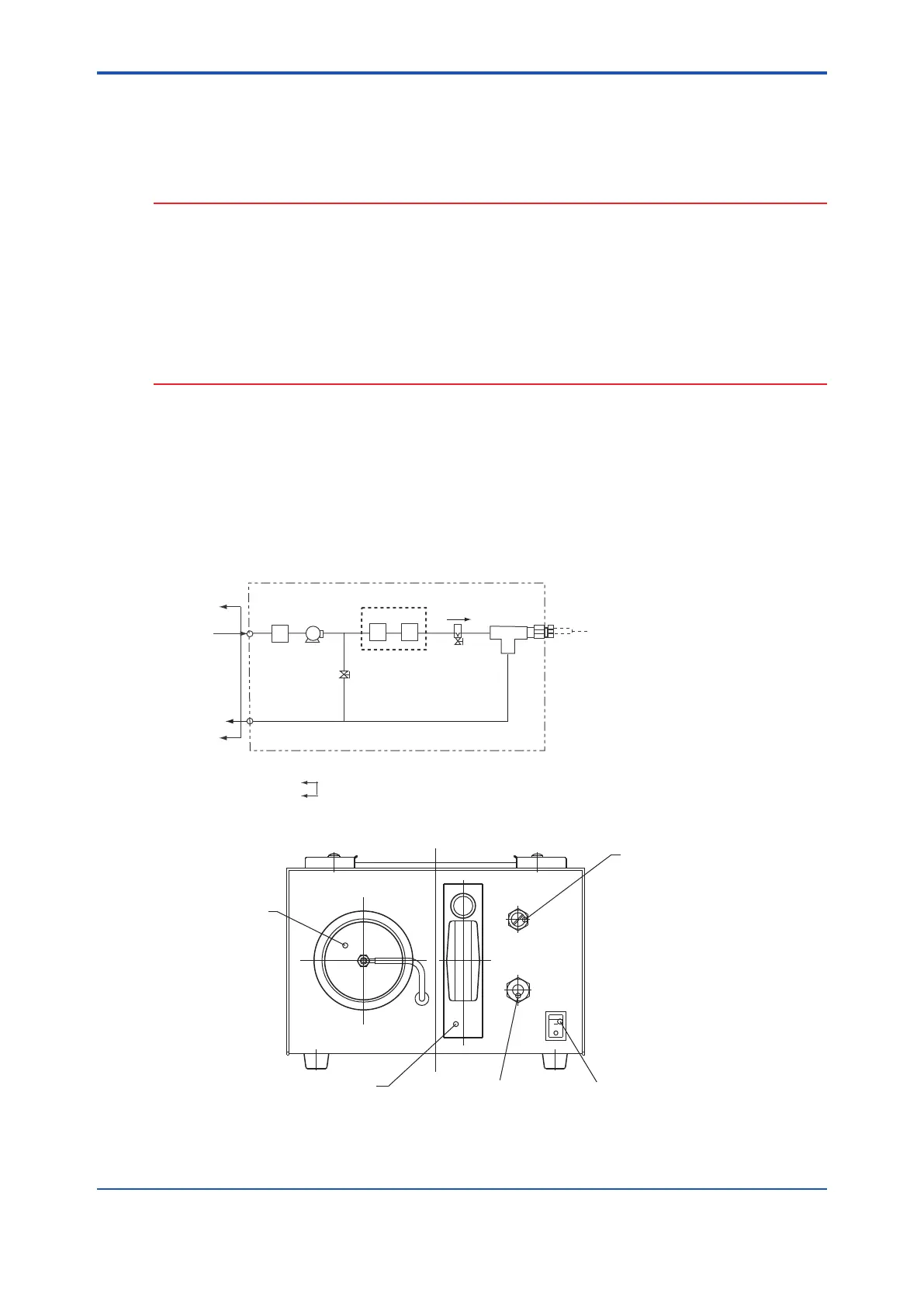

Activated Carbon

Filters: F2 + F3

Flowmeter: FM1

Sensor Connector, 8 mm O.D.

Switch

Needle Valve: V1

Figure2. SamplingUnit

4th Edition : Oct. 23, 2019-00

Loading...

Loading...