● Required straight pipe lengths and recommendations (2)

D: Nominal diameter of vortex owmeter (mm)

Description Figure

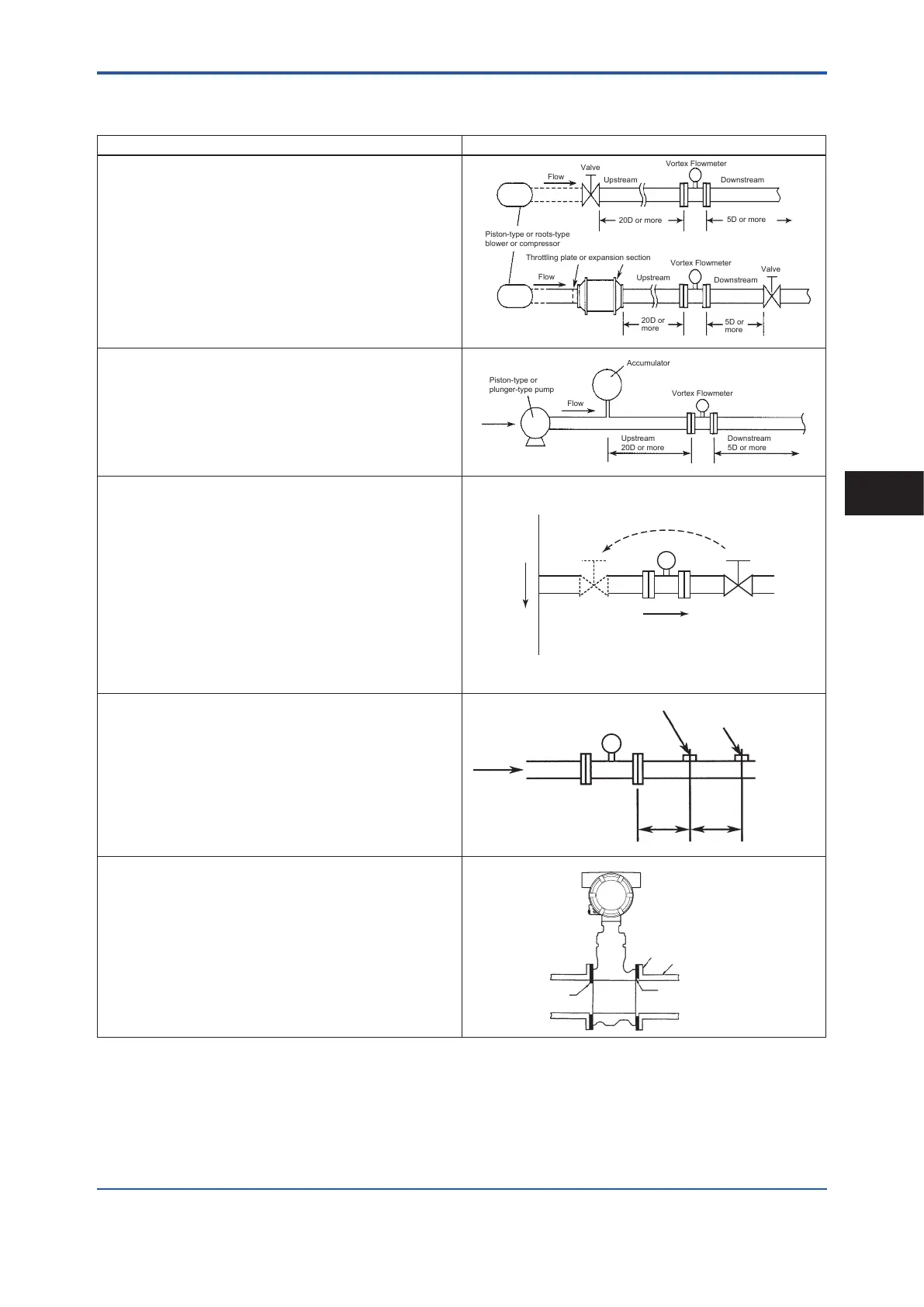

● Fluid vibration

Fluid vibration may occur in a gas line or high-pressure liquid

line (approximately 1 MPa or more) that uses a piston-type or

roots-type blower or compressor. In these cases, install the vortex

owmeter on the downstream side of the valve at a distance of 20D

or more, and ensure a length of 5D or more on the downstream

side of the owmeter. If the piping design requires that a valve be

installed on the downstream side of the vortex owmeter, install

a vibration damping device such as throttling plate or expansion

section on the upstream side of the vortex owmeter.

Vortex Flowmeter

Vortex Flowmeter

Upstream

Upstream

Downstream

Downstream

Flow

Valve

Valve

Flow

Piston-type or roots-type

blower or compressor

Throttling plate or expansion section

20D or

more

5D or

more

20D or more

5D or more

● Installing near a pump

If a piston-type or plunger-type pump is used, install an

accumulator on the upstream side of the vortex owmeter to

reduce uid vibration in the piping.

Vortex Flowmeter

Accumulator

Flow

Piston-type or

plunger-type pump

Upstream

20D or more

Downstream

5D or more

●Eect of pulsation pressure due to T-type piping

If pulsation pressure occurs due to T-type piping, install a valve on

the upstream side of the vortex owmeter.

Example: As shown in the gure, when the ow rate of A is zero

because V1 is closed, pulsation pressure is detected when B is

owing, which causes the zero point of the meter to uctuate. To

prevent this from occurring, change the valve installation location

to V1'.

Note: In case of the Reduced Bore Type, moisture may be

remained upstream of the owmeter. Drain it appropriately.

Relocating

Valve (Off)

A

Flow

V1’ V1

Vortex Flowmeter

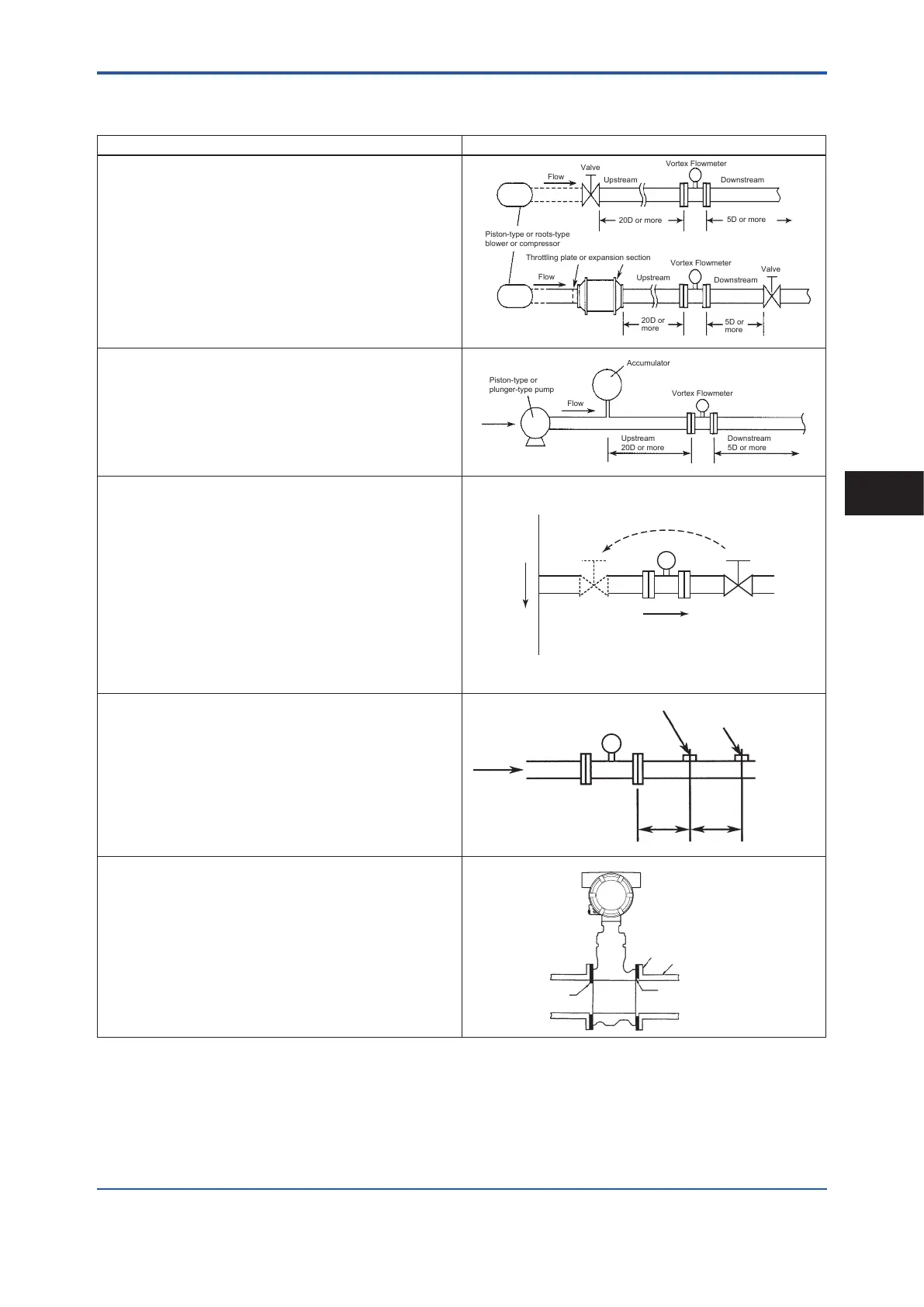

● Pressure and temperature taps

When temperature/pressure compensation is to be performed,

install a pressure tap on the downstream side of the vortex

owmeter at a distance of 2D to 7D.

Then install a temperature tap on the downstream side of the

pressure tap at a distance of 1D to 2D.

When using a temperature tap only, install it on the downstream

side of the vortex owmeter at a distance of 3D to 9D.

Temperature tap

Upstream

2 to 7D 1 to 2D

Vortex Flowmeter

Flow

● Mounting gasket

Avoid mounting gaskets that protrude into the pipe line, as this

may cause inaccurate readings.

Use gaskets with bolt holes to prevent protrusion into the piping

line. When using a spiral gasket (without bolt holes), conrm the

size with the gasket-manufacturer, as standard items may not be

used for certain ange ratings.

Flange of adjacent pipe

Adjacent pipe

Make sure gasket does

not protrude

<3. Installation>

13

IM 01F07A01-01EN

Installation

3

Loading...

Loading...