● Required straight pipe lengths and recommendations (3)

Description Figure

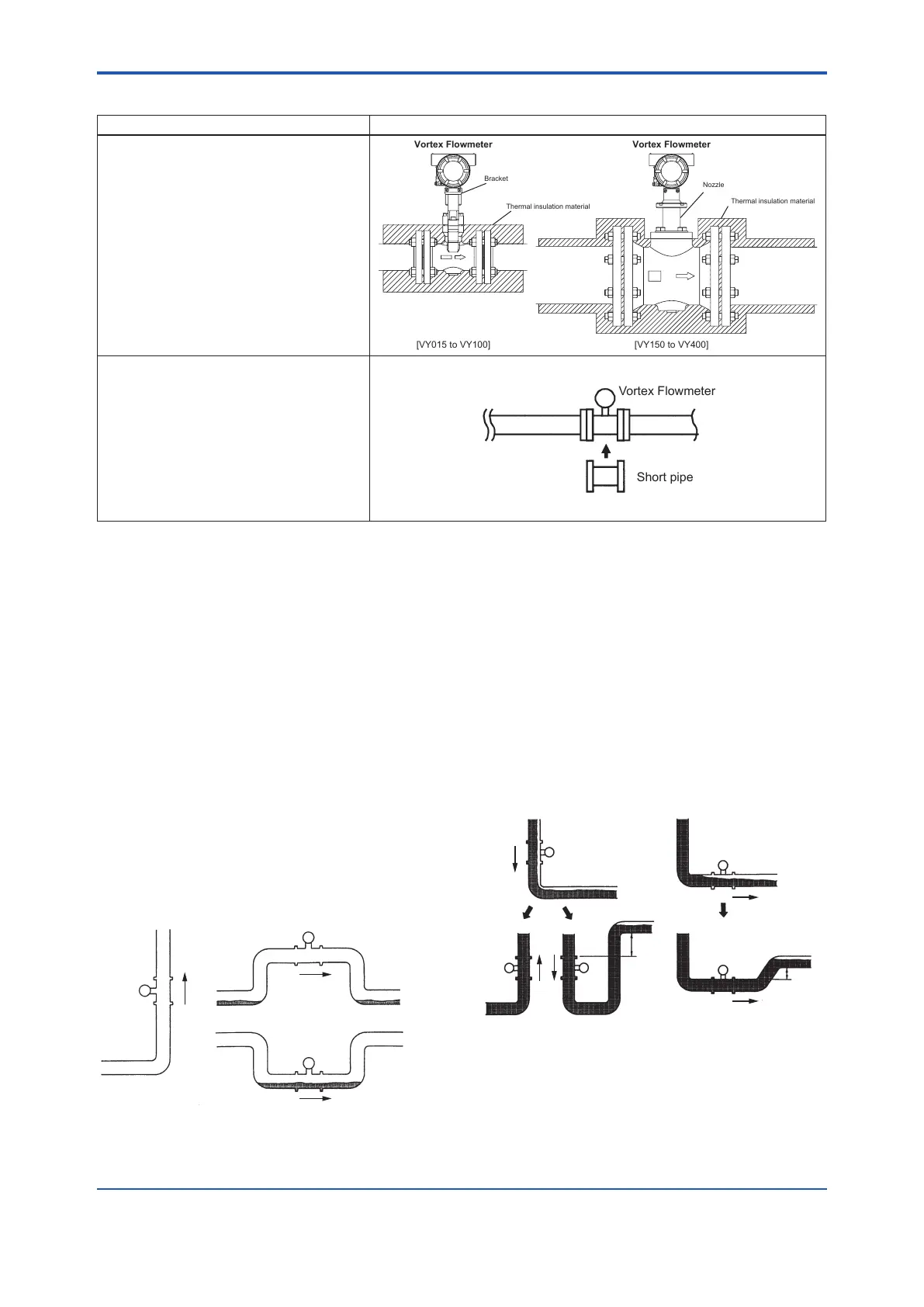

● Thermal insulation of integral

owmeter and remote sensor

When applying thermal insulation to a pipe

carrying high-temperature uid, do not wrap the

insulating material around the bracket (VY015 to

VY100) or the nozzle (VY150 to VY400).

Nozzle

Thermal insulation material

[VY015 to VY100]

Vortex Flowmeter

Vortex Flowmeter

[VY150 to VY400]

Thermal insulation material

● Flushing (cleaning) the pipe

If there is a possibility of scaling or sludge

(boiling scale, mud) inside newly installed or

repaired piping, ush the piping before operation.

When performing ushing, use bypass piping

to avoid damaging the owmeter. If there is no

bypass piping, install a short pipe in place of the

owmeter when performing ushing.

■ Mounting Precautions

Be sure to observe the following items so that

the performance of the vortex owmeter is fully

demonstrated.

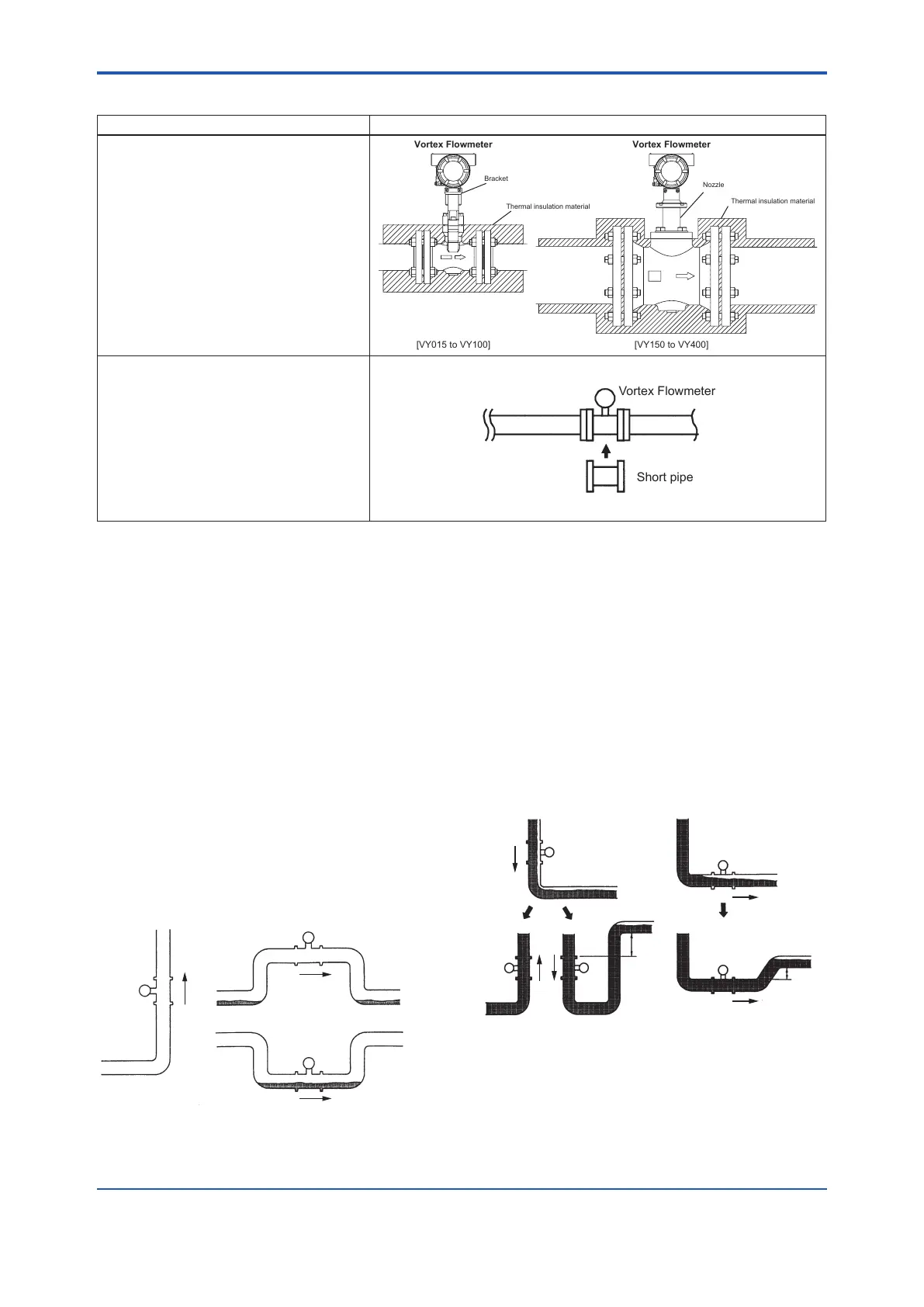

(1) Gas or Steam Measuring Precautions

Ensure that accurate measurement can be

performed with the piping line lled with the uid

that ows through.

● Piping to Prevent Liquid Traps

Mount the vortex owmeter in a vertical pipeline

to avoid liquid traps. When the vortex owmeter is

installed horizontally, raise the part of the piping line

in which the vortex owmeter is installed.

F0302.ai

(Good)

(Good)

(No Good)

Flow

Flow

Flow

(2) Liquid Measurement Precautions

The owrate cannot be measured accurately if

the piping line is not lled with uid. When piping,

observe the following precautions.

● Maintaining a Filled Pipe State

Make the uid ow against gravity upwards from

below. When the uid is owing with gravity, lift

the down-stream pipe length above the vortex

owmeter installation level to maintain a lled pipe

state at all times.

Flow

Flow

Flow

Flow

(No Good) (No Good)

(Good)

(Good)

h h>0

h

h>0

F0303.ai

<3. Installation>

14

IM 01F07A01-01EN

Loading...

Loading...