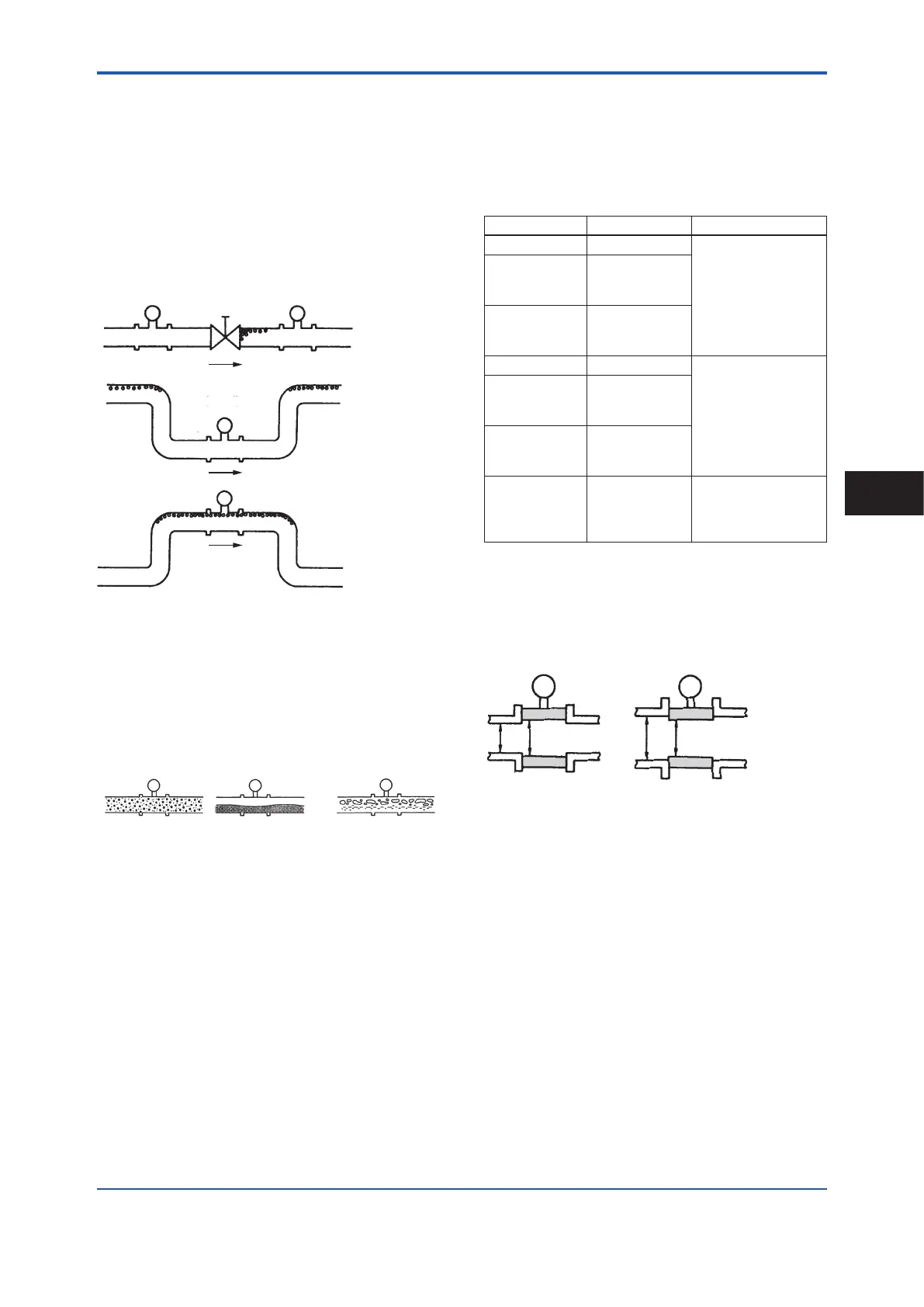

● Piping for Avoiding Bubbles

Flows containing both gas and liquid may not satisfy

the accuracy specications of the instrument.

Prevent gas bubbles from forming in a liquid ow.

Piping should be carried out to prevent the build-

up of gas bubbles in the vortex owmeter. Also,

install the valve on the downstream side of the

vortex owmeter because pressure drop across the

control valve may cause gas to liquefy.

F0304.ai

Flow

Flow

Flow

(Good)

(Good)

(No Good)

Value

(No Good)

(3) Multi-Phase Flow

The vortex owmeter can measure gas, liquid and

steam within the same structure. However, accurate

measurement of mixed ows (e.g. gas and liquid) is

not possible.

Mist flow

Stratified flow

Bubble flow

(No Good) (No Good) (No Good)

gas

liquid

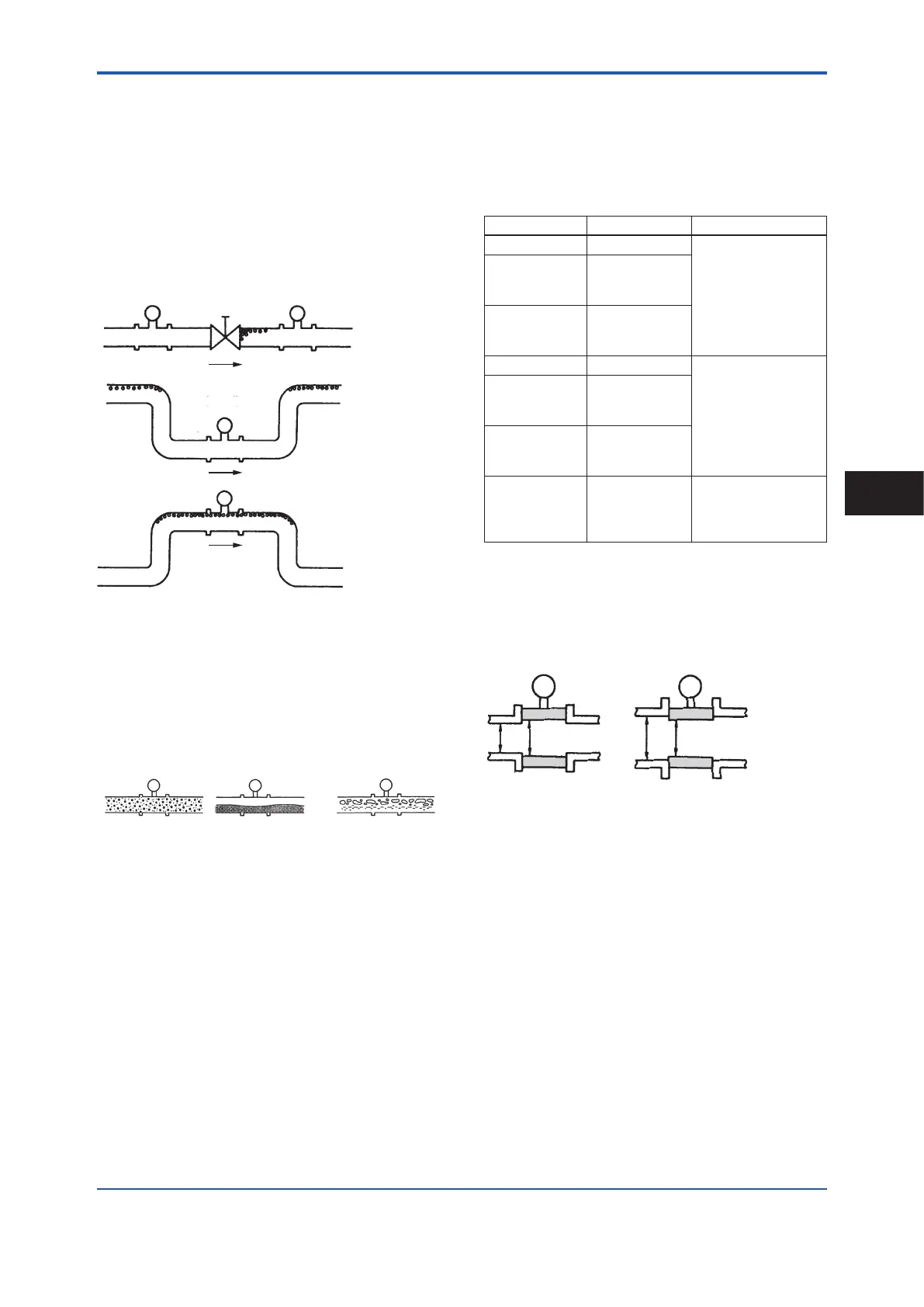

(4) Diameter of Adjacent Pipes and

Concentricity of Inner Diameters in Vortex

Flowmeter

Use the adjacent pipes which have a larger inner

diameter than that of the vortex owmeter. Refer to

the table below.

Model code Type of body Adjacent pipe

VY015 to VY050 -0: General type Sch40 or pipe with

larger inner diameter

than Sch40

VY025 to VY080

-1: Reduced

bore type (1 size

reduction)

VY040 to VY100

-2: Reduced

bore type (2 size

reduction)

VY080 to VY400 -0: General type Sch80 pipe with larger

inner diameter than

Sch80

VY100 to VY200

-1: Reduced

bore type (1 size

reduction)

VY150 to VY200

-2: Reduced

bore type (2 size

reduction)

VY025 to VY150

-4: High pressure

reduced bore

type (1 size

reduction)

Sch160pipe with larger

inner diameter than

Sch160

• Ensure that the piping and pipe of the vortex

owmeter are concentric.

• Ensure that the gaskets of adjacent pipes do

not protrude into the piping line.

F0306.ai

(No Good) (Good)

D

1

D

1

<

D

2

D

1

≥

D

2

D

2

D

1

D

2

(5) Other

The degree of protection of the vortex owmeter is

of IP66/IP67 (JIS C 0920, IEC60629) or Type 4X

(NEMA250). Therefore, it cannot be used under

water.

<3. Installation>

15

IM 01F07A01-01EN

Installation

3

Loading...

Loading...