IM 01C50B01-01E

6-4

6. MAINTENANCE

6.4 Troubleshooting

When the measured value is found abnormal, follow

the troubleshooting flowchart below. If the complex

nature of the trouble means that the cause cannot be

identified using the following flowchart, refer the

matter to our service personnel.

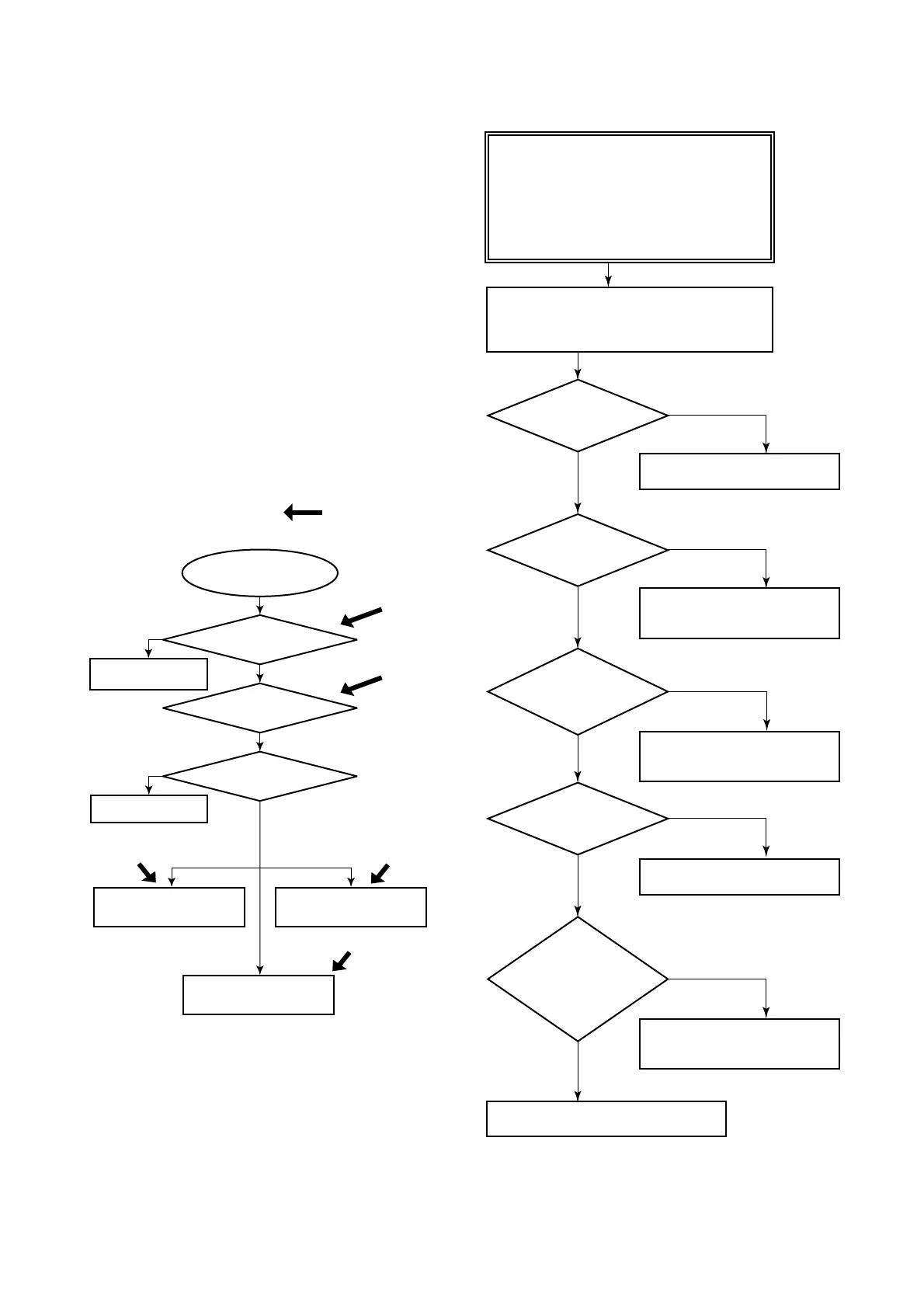

6.4.1 Basic Troubleshooting Flow

When the process measurement is found to be abnor-

mal, it is necessary to determine whether the input

temperature is out of range, the sensor has failed or

being damaged, or the unit has been improperly wired.

If it is suspected that the measurement system is the

source of the problem, use the flowchart to identify the

affected area and determine how to proceed.

In these troubleshooting steps, the self diagnostic

function provides helpful solutions to the problem,

refer to the instructions in Section 6.5 for details.

YES

YES

NO

NO

F0604.EPS

Measured value

is found faulty

Error in process

variable?

Faulty

area in measurement

system

Receiver error

Operating requirements:

check, study, correction

Check the transmitter

Environmental condition:

check, study, correction

Environmental condition

Operating requirements

Error in measurement

system

Transmitter

Inspect receiver

Inspect the process

:Part supported

by self-diagnosis

Figure 6.5 Basic Flow and Self-diagnosis

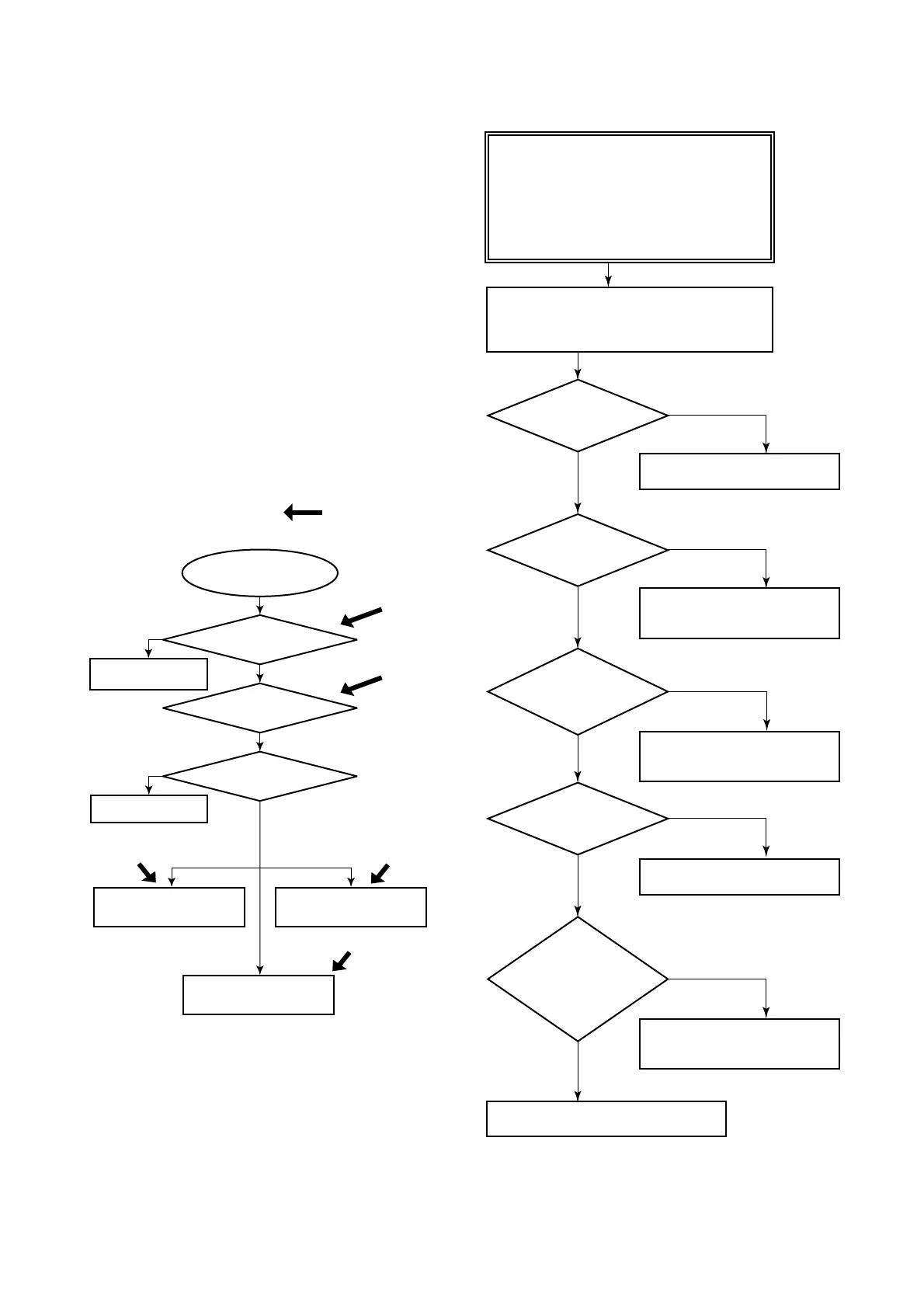

6.4.2 Example of Troubleshooting Flow

F0605.EPS

YES

NO

NO

YES

NO

YES

NO

NO

YES

YES

Was a faulty

area found with self-

diagnosis?

Is the polarity

of the power supply

correct?

Are the power

supply voltage and load

resistance correct?

Is the sensor

correctly connected?

Is there a

disconnection in the loop?

Do the loop numbers

correspond to the

counterpart?

The following phenomena indicate that this

instrument may be out of operation.

[Example]

• No output signal is delivered.

• Process variable changes but the output

signal remains unchanged.

• The assessed value of the process variable

and the output are not coincident.

Refer to our service personnel for details.

• If a built-in indicator is attached, check the

display of the error code.

• Connect a hand-held terminal and check

self-diagnosis.

Refer to the error message list and

check for recovery measures.

Check the polarity between the

power supply and terminal box and

correct it.

Refer to Section 5.2 and set

the specified voltage and load

resistance.

Check the sensor connection and

correct it.

Check for disconnection or faulty

wiring and take corrective

measures.

Figure 6.6 Example of Troubleshooting Flow

Loading...

Loading...