Confirming a vacuum

Use a vacuum gauge to measure a target vacuum. However, it is not possible to read the vacuum

gauge installed in the manifold accurately. Use a digital vacuum measuring device.

Water evaporation

In atmospheric pressure, water boils at 212°F (100°C). However, each time the pressure in the pipes

reaches a vacuum state, water boils at a lower temperature than 212°F (100°C). The lower this

temperature is, the easier the water evaporators and vacuum drying occurs.

If there is a possibility of dew condensation, the vacuuming time must be controlled more strictly

because water does not evaporate easily and it is difficult to know the degree of dew condensation.

130 Pa (1,000 microns) is a guideline to control the vacuum grade.

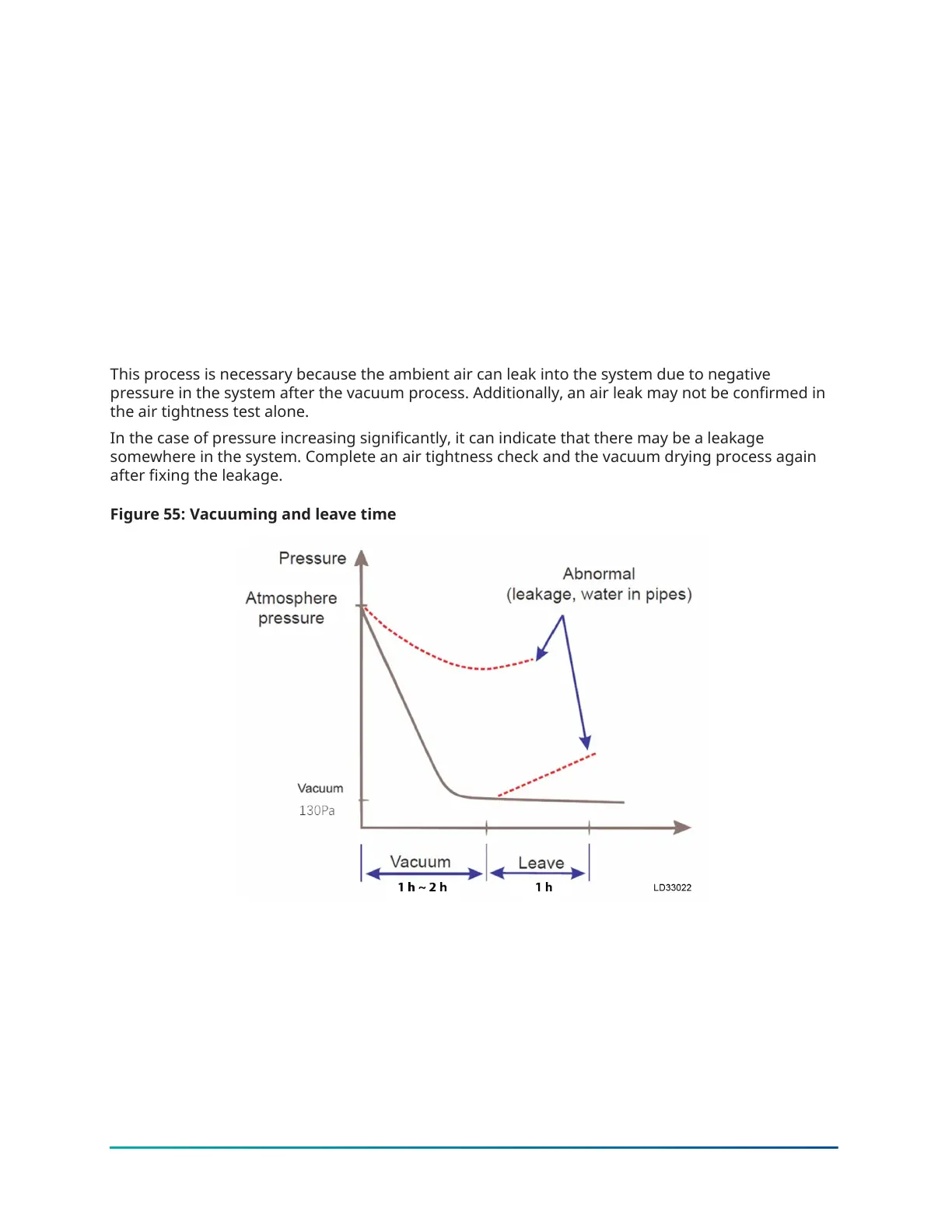

After finishing vacuuming, close the manifold valve and stop the vacuum pump. Leave the unit for 1

h to confirm that the pressure measured by a vacuum gauge has not increased.

This process is necessary because the ambient air can leak into the system due to negative

pressure in the system after the vacuum process. Additionally, an air leak may not be confirmed in

the air tightness test alone.

In the case of pressure increasing significantly, it can indicate that there may be a leakage

somewhere in the system. Complete an air tightness check and the vacuum drying process again

after fixing the leakage.

Figure 55: Vacuuming and leave time

YMAE Air-Cooled Inverter Scroll Chiller and Heat Pump76

Loading...

Loading...