3D Systems, Inc.

28

p/n: 15-D99, rev. C

UTILITIES AND EQUIPMENT REQUIREMENTS

6.1 Atmosphere Requirements

6.1.1 Room Ventilation

The printing process takes place under an inert argon atmosphere inside the process chamber. During the preparation, loading,

and unloading, argon gas is released to the workplace. In small rooms, argon volumes exhausted into the room may be

The printing process takes place under an inert argon atmosphere inside the process chamber. During the preparation and

loading /unloading, the machine argon gas is released to the workplace. Therefore, in small rooms, a minimum ventilation is

required.

During cleaning of the machine, powder particles/dust may become airborne. The presence of metal powders in the work

area air is unsafe and must be avoided as much as possible. Therefore adequate room ventilation is recommended, as well as

wearing PPE (Personal protective equipment).

A. Air Conditioning

The facility air conditioning system where the printer is operating should be capable of dissipating 1.0 kW (3412 Btu or 0.28 ton

U.S. refrigeration) of heat or equivalent to keep temperature requirements. Ensure that any air conditioning ducting does not

vent directly onto the machine.

B. Room Air Source

The facility HVAC system provides source air only. Air that is introduced into the room is not allowed to recirculate back into

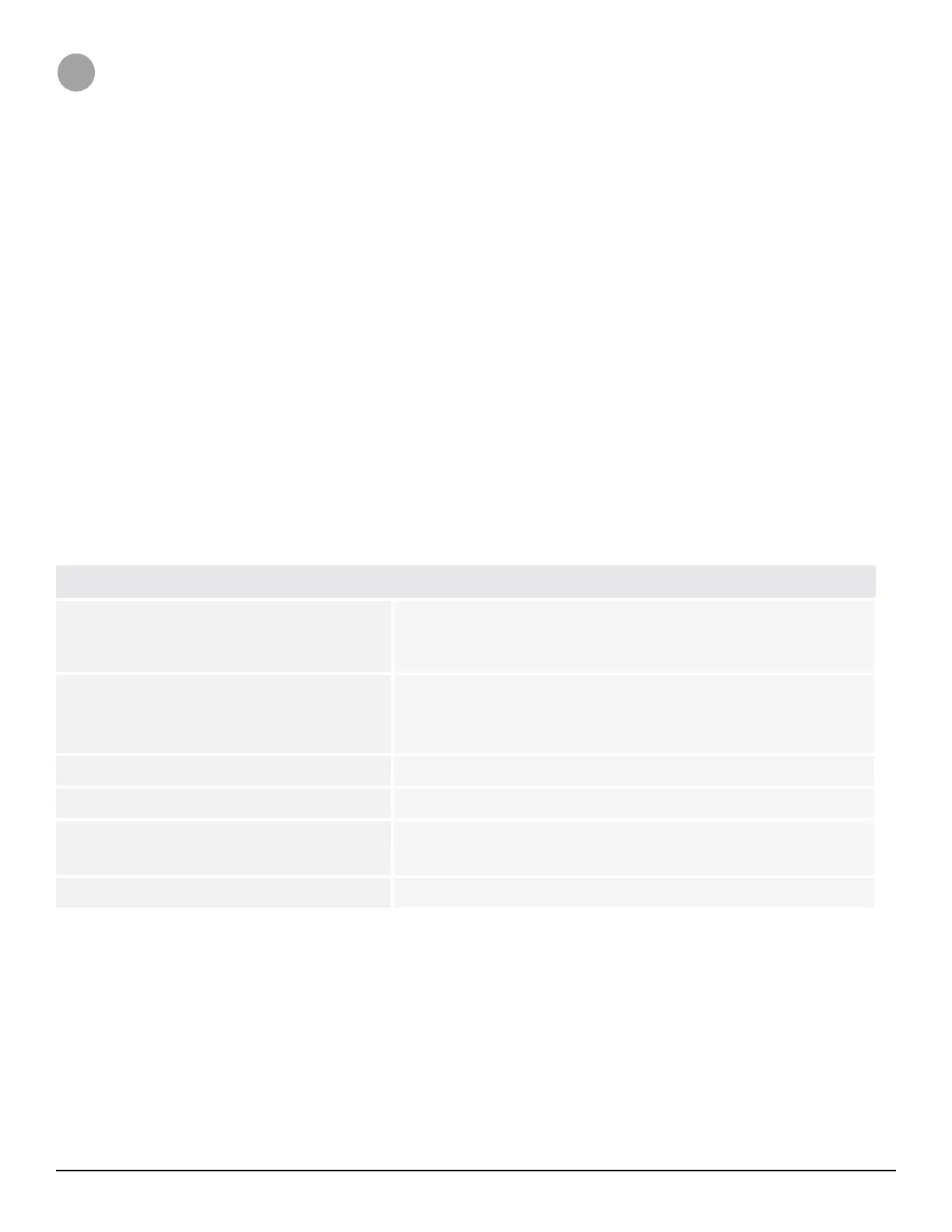

ATMOSPHERIC VARIABLES REQUIREMENTS

Room temperature controls

End user must ensure constant temperature in operating room.

Heating and air conditioning may be required.

In case of A/C present, it should not blow on top of process station.

Temperature

Operating range: (16 to 27) °C; (60 to 80) °F

Setpoint range: (18 to 24) °C; (65 to 75) °F

Stability: ± 2 °C (± 5 °F)

Non-condensing relative humidity No lower than 20% and no higher than 80%

Room air changes 4 per hour minimum

Heat dissipation

Maximum: 3.2 kW (11000 BTU/hr)

Average: 2.4 kW ( 8200 BTU/hr)

Atmospheric corrosives None; Clean Dry Air (CDA) is required

Loading...

Loading...