3D Systems, Inc.

5

p/n: 15-D99, rev. C

EQUIPMENT AND PACKAGING

3.1 Equipment

This section lists all of the equipment that is provided as a part of the DMP Flex 350 system.

PRODUCTION PRINTER SUBMODULES

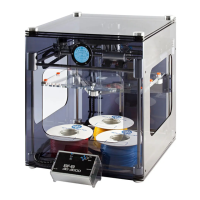

DMP Flex 350

• Process chamber

• Electrical cabinet

• Blower

•

• Transport cart

• Sieving station (optional)

3.2 Crated Weights and Dimensions

3D Systems expedites the assembly and sub-assembly parts in wooden transport crates. The Centre Of Gravity (COG) of the

packed wooden crate is indicated on the wooden crate. Mark that the COG of the assembly or sub-assembly part is indicated

on supplied drawings. Mark that the wooden crates are equipped with forklift-pockets. 3D Systems states the underneath

dimensions for: logistical purposes internal at the facility of the client, plant – and building access.

The wooden crates have the following dimensions and weight:

ASSEMBLY W (MM / INCH) D (MM / INCH) H (MM / INCH) MASS (KG / LBS)

Printer module 2540 / 100 1830 / 72 2760 / 109 4400 / 9700

Printer ancillaries 2200 / 87 1840 / 73 1920 / 76 1100 / 2425

Chiller 580 / 23 790 / 31 470 / 19 58 / 127

3.3 Storage Requirements

The packaging consists of crates with physical-chemical protection. The corrosion protection is guaranteed by a seal wrapping

position protected from impact.

3.3.1 Recommended Storage Conditions

• Dust free environment

• Frost free environment

• Indoor location

• Humidity level: 20% - 80%

• Storage temperature: 5° C - 40° C (40° F - 105° F)

3.4 Noise Emission

The DMP Flex 350 is in scope with Machinery Directive 2006/42/EC on noise emissions. The noise emission measurements were

performed on a DMP Flex 350 compact setup, including printer, blower, chiller and vacuum pump.

3.4.1 Measurement Device

All measurements are performed with the following device:

Testo 815

•

• Date of calibration: 03/07/2018

• Calibrated by: Calimet Calibration

Loading...

Loading...