Camshafts

Inspection

4,

5.

9.

1.

Remove

the bolts, then remove the camshaft hold-

ers from the cvlinder head.

NOTE: Unscrew the camshaft holder

bolts two

turns at a time, in a crisscross

pattern.

Lift camshaft out of cylinder head. wipe clean,

then

inspect lift ramps. Replace camshaft if lobes

are

pit-

ted, scored, or excessively worn.

Clean

the camshaft bearing surfaces in the cylinder

head. then set camshaft

back

in

place.

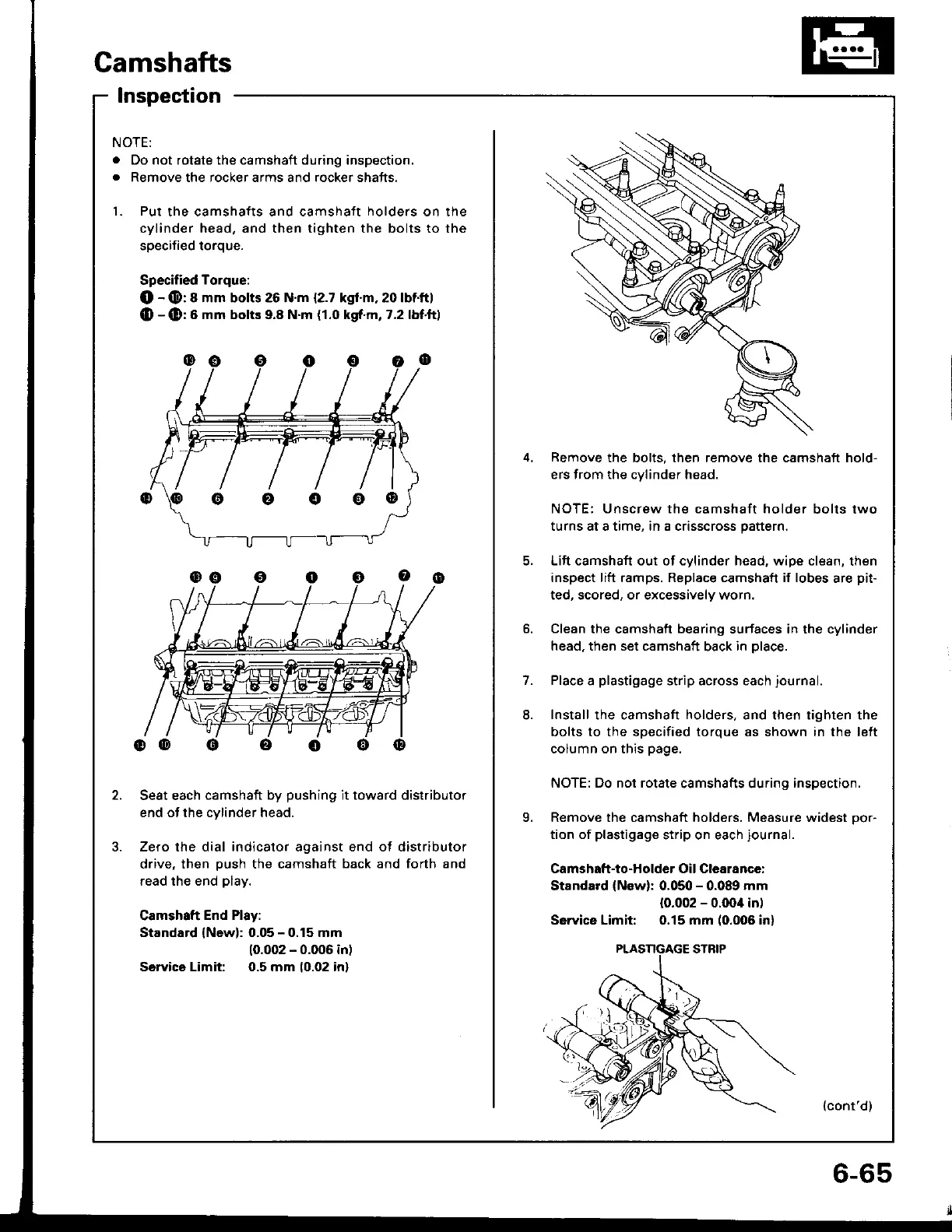

Place

a

plastigage

strip across each

journal.

Install

the camshaft

holders,

and then tighten the

bolts to the specified torque as shown in the left

column on this

page.

NOTE: Do not rotate

camshafts during

inspection.

Remove the camshaft holders. Measure widest Dor-

tion of

plastigage

strip on each

journal.

Camshaft-to-Holder Oil Clearance:

Standard

{New):

0.050

-

0.089

mm

{0.002

-

o.Ooil in)

Sswice Limit: 0.15 mm

(0.006

in)

(cont'dl

NOTE:

.

Do not rotate the camshaft during inspection.

.

Remove the rocker arms and rocker shafts.

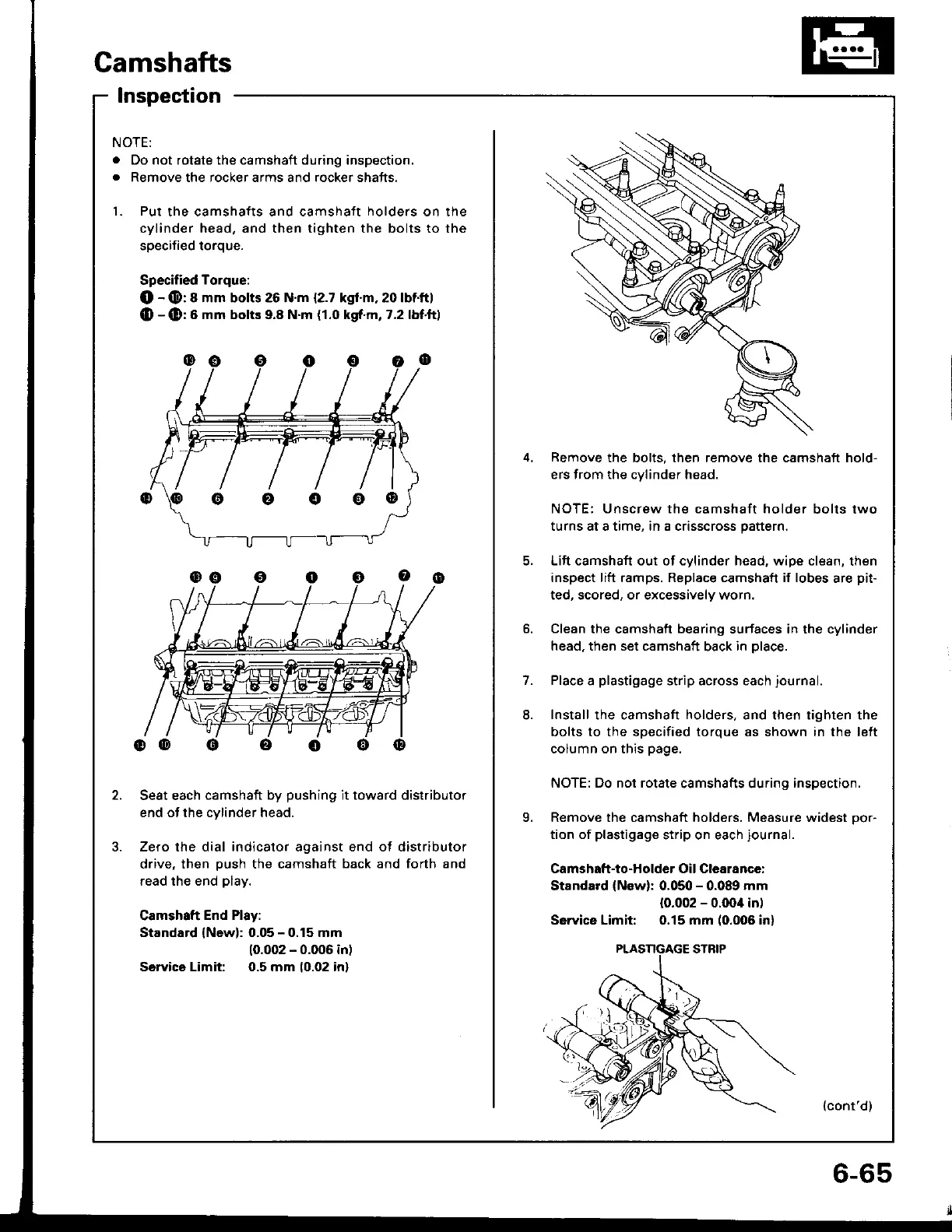

1. Put

the camshafts and camshaft

holders

on the

cylinder head, and then tighten the bolts to the

soecified torque.

Specified

Torque:

O

-

@:

8 mm bolts 26 N.m

{2.7

kgl.m,20 lbt'ftl

(D

-(D:6

mm bolts 9.8 N.m

{1.0

kgt.m, 7.2 lbf'ftl

Seat each

camshaft by

pushing

it toward distributor

end of the cylinder head.

Zero the dial indicator against end of distributor

drive, then

push

the camshaft

back and forth and

read the end

play.

Camshaft

End Play:

Standard

(New):

0.05

-

0.15 mm

10.002

-

0.006 inl

Sawics Limit: 0.5 mm

(0.02

inl

oooo@

Loading...

Loading...