EndPlay

NOTE; End

play

should be

inspected before removing

crankshaft.

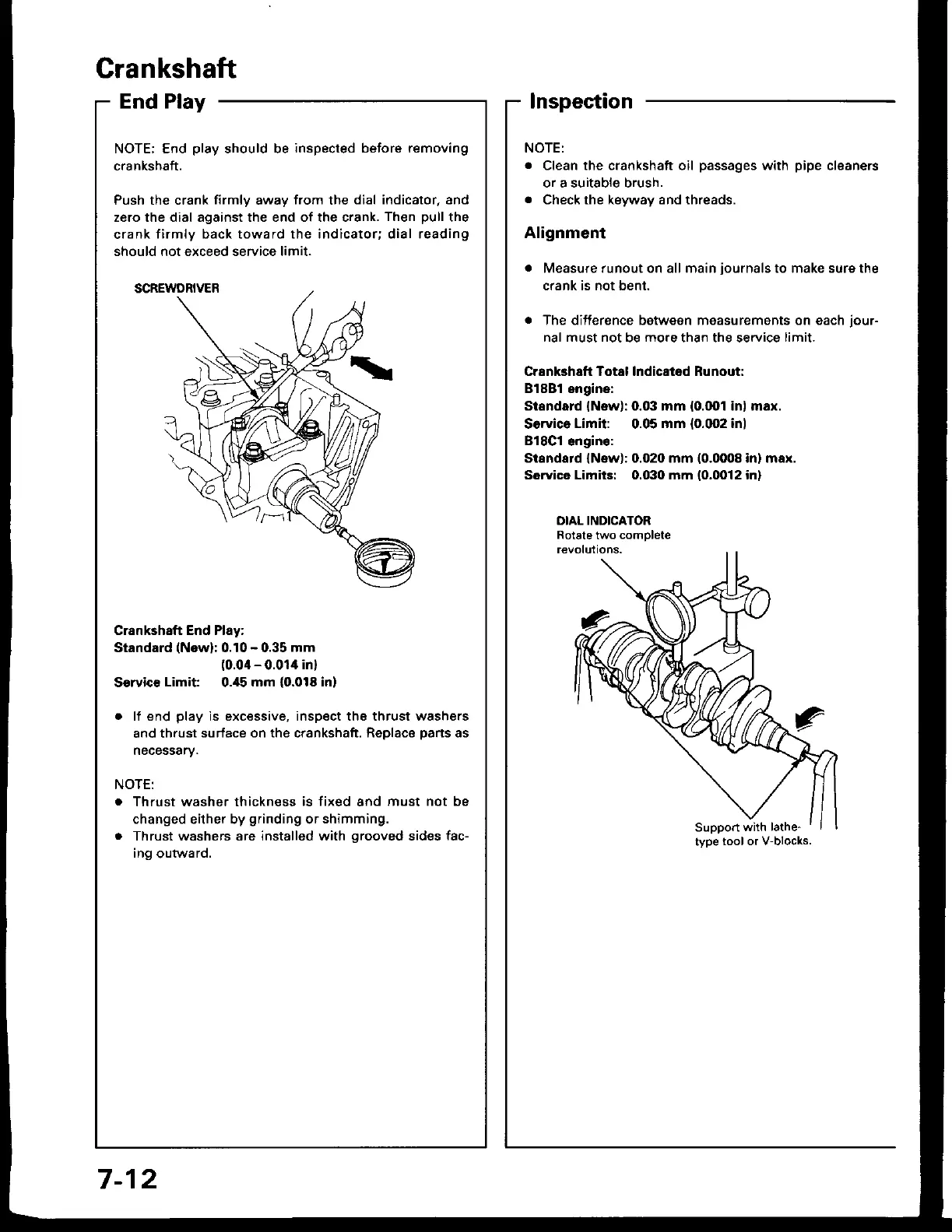

Push the crank

firmly

awav

from

the

dial indicator, and

zero the dial against the end of the crank.

Then

pull

the

crank

firmly back toward the indicator; dial reading

should not exceed service limit.

Crankshaft End Play:

Standard

(New):

0.10

-

0.35

mm

(0.04

-

0.01i|

inl

S€rvic€

Limit

0.i15

mm

(0.018

inl

.

lf end

play

is excessive, inspect the thrust wash€rs

and thrust

surface on the crankshaft. Replace

pans

as

necessary.

NOTE:

Thrust washer thickness

is fixed

and

must not be

changed either by

grinding

or shimming.

Thrust washers are installed with

grooved

sides

fac-

ing

outward.

Crankshaft

lnspection

.

Clean the crankshatt oil

passages

with

pipe

cleaners

or a suitable brush.

.

Check the keyway and threads.

Alignment

Measure runout on all main

journals

to make sure the

crank is not bent.

The differ€nce between measurements on each

jour-

nal must not

be

more

than the service

limit.

Crank3haft Total lndicatod Runout:

Bl8Bl engins:

Sisndod

{Nsw):

0.03 mm

{0.001

in) max.

Sorvice

Limit:

0.05

mm

{0.002

inl

818C1

engin€:

Standard

{Nsw):

0.020 mm

(0.0008

in} mar.

SGrvice Limits: 0.030 mm 10.0012 in)

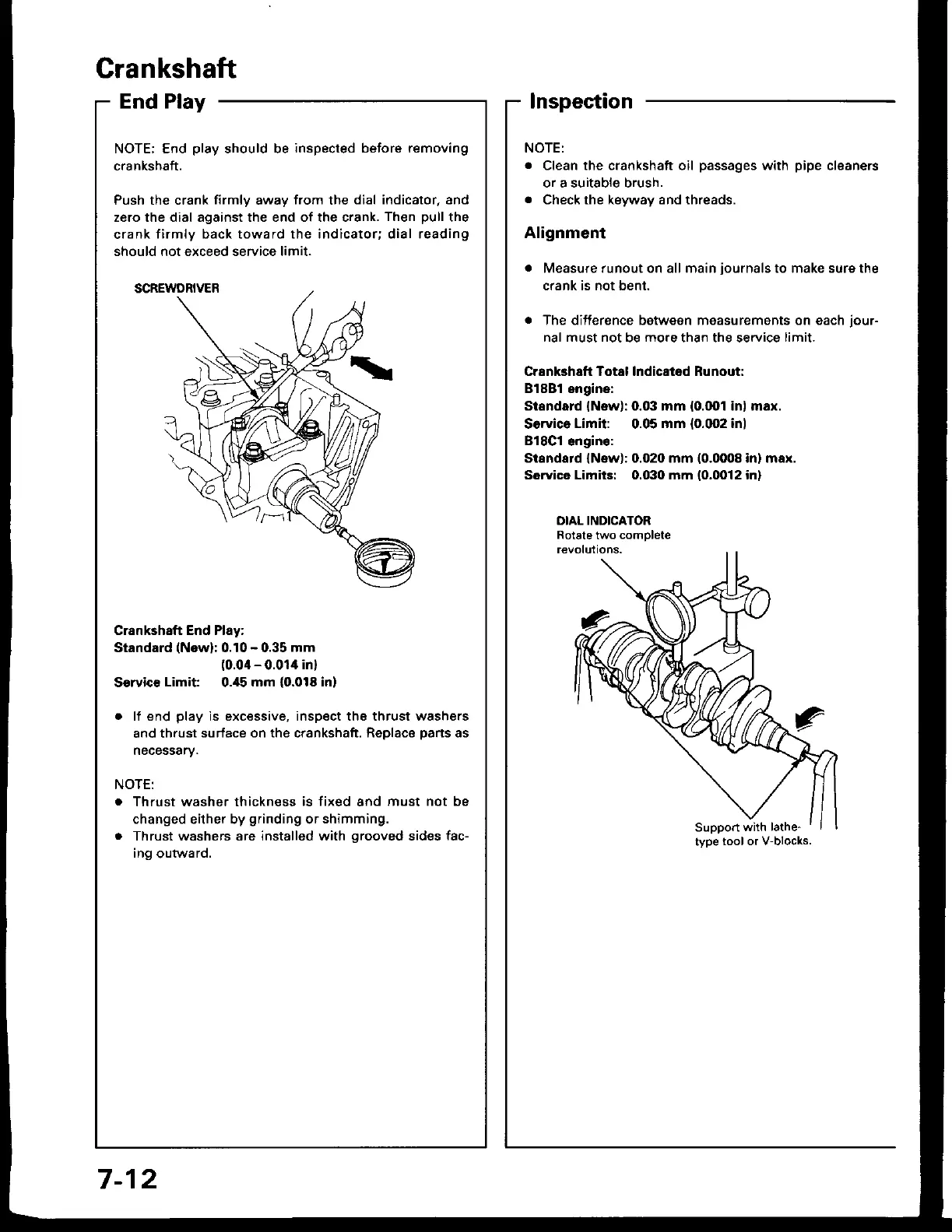

OIAL INDICATOR

Rotate

tlvo

complete

revolutions.

Support

with lathe-

7-12

Loading...

Loading...