Valve lnstallation

When installing

valves in cylinder head, coat

valve

stems

with oil before inserting

into valve

guides,

and

make

sure

valves move up and down

smoothly.

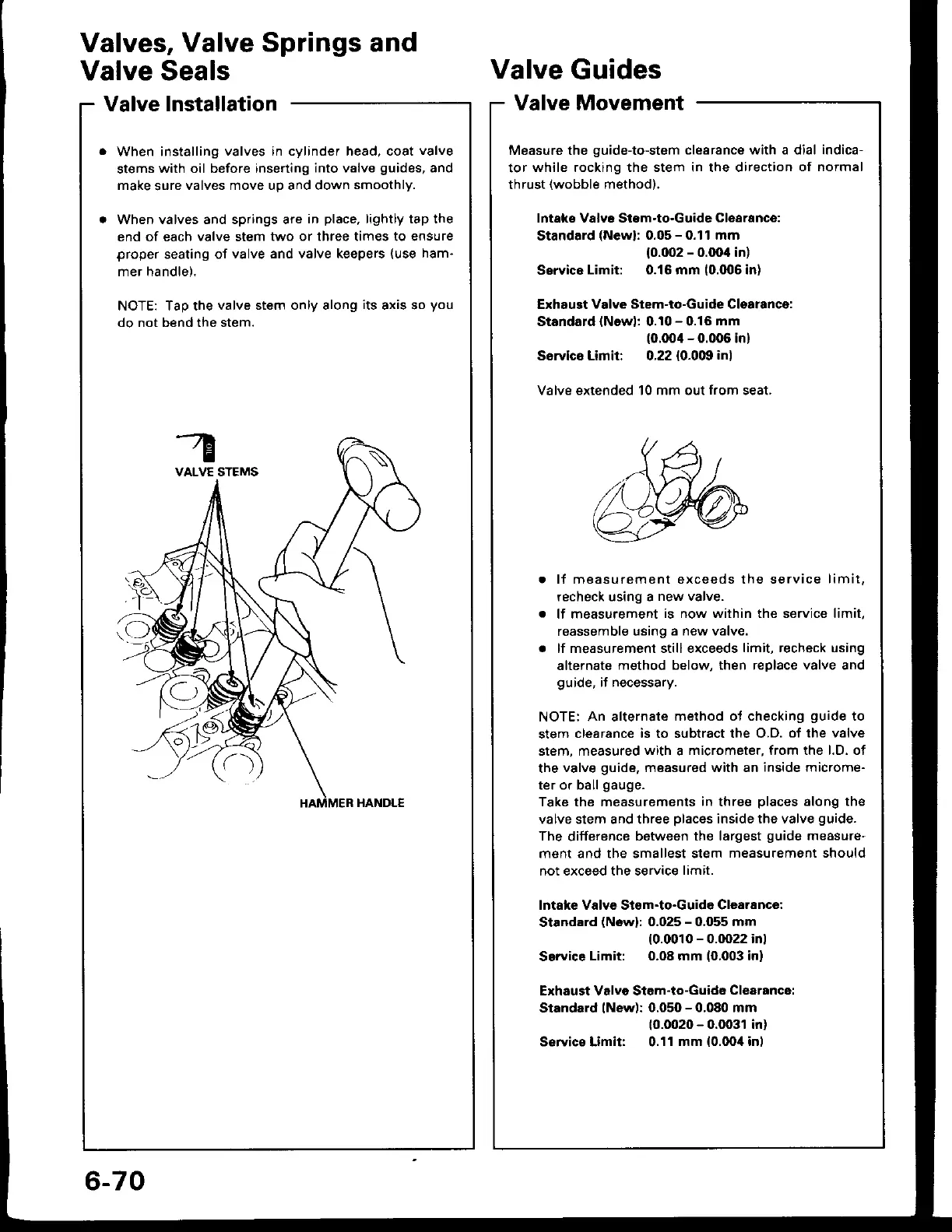

When valves and springs are

in

place,

lightly tap the

end of each valve stem

two or three times to ensure

proper

seating of

valve and valve keepers

(use

ham-

mer handle).

NOTE: Tap the

valve stem only along

its

axis so

you

do not bend the stem.

Valves,

Valve Springs and

Valve Seals

Valve

Guides

Valve Movement

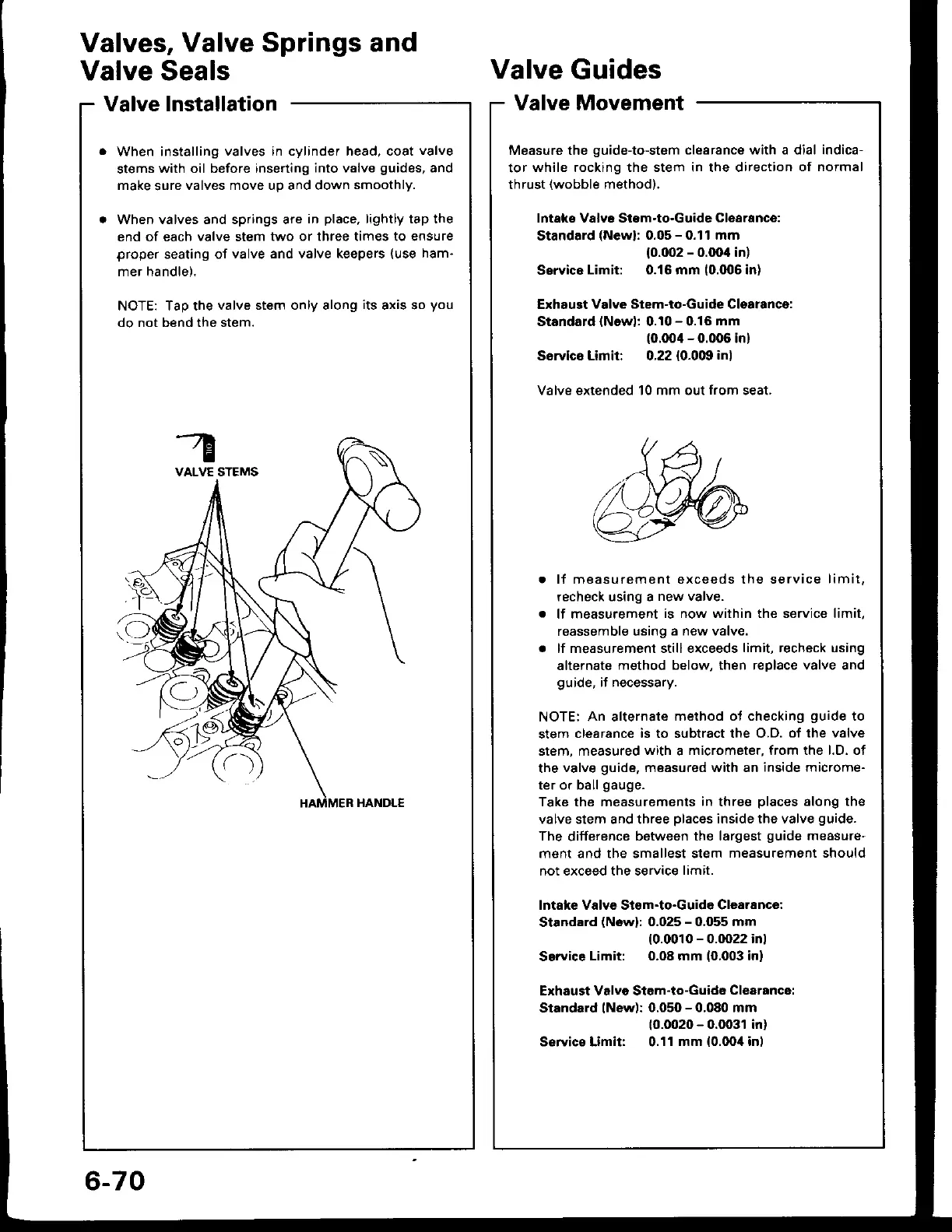

Measure the

guide-to-stem

clearance with a dial indica-

tor

while rocking the stem in the direction

of normal

thrust

(wobble

method).

lntaks Valvr Stom-to-Guide

Clearance:

Standard

(Newl:

0.05

-

0.11 mm

{0.002

-

0.OO'l in)

Ssrvice

Limit: 0.16 mm

(0.006

in)

Exhaugt

Vdve Stem-to-Guide Clsarancg:

Standald

lNowl:

0.10

-

0.16

mm

(0.00'l

-

0.006 in)

Sorvics Limit: 0.22 {0.0m

in)

Valve extended 10 mm out

from

seat.

.

lf measurement exceeds the service

limit.

recheck using a

new valve.

.

lf measurement

is now within the service limit,

reassemble using

a new valve.

.

lf measurement still exceeds

limit, recheck using

alternate

method below, then replace valve and

guide,

if necessary.

NOTE: An alternate

method ot checking

guide

to

stem

clearance is to subtract the O.D.

of the valve

stem. measured

with

a

micrometer, from the l.D. ot

the

valve

guide,

measured with an

inside microme-

ter or ball

gauge.

Take the measurements

in

three

places

along the

valve stem and three

places

inside the valve

guide.

The

difference

between the largest

guide

measure'

ment and the smallest stem

measurement should

not exceed the service

limit.

lntafte Valvs Stom-to-Guida Clearance:

Stardard

(Nowl:

0.025

-

0.055 mm

(0.0010

-

0.0022 inl

Service

Limit: 0.08 mm

(0,003

in)

Exhaust Valvo Stem-to-Guide

Clearance:

Standard lNew):

0.050

-

0.080 mm

10.0020

-

0.0031 in)

S€rvics Limit: 0.11

mm

{0.0oil

inl

6-70

Loading...

Loading...